A method for making a pure electric vehicle battery box assembly

A pure electric vehicle and battery box technology is applied in the field of making pure electric vehicle battery box assemblies to achieve the effects of flame retardant smoke density, low smoke density and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

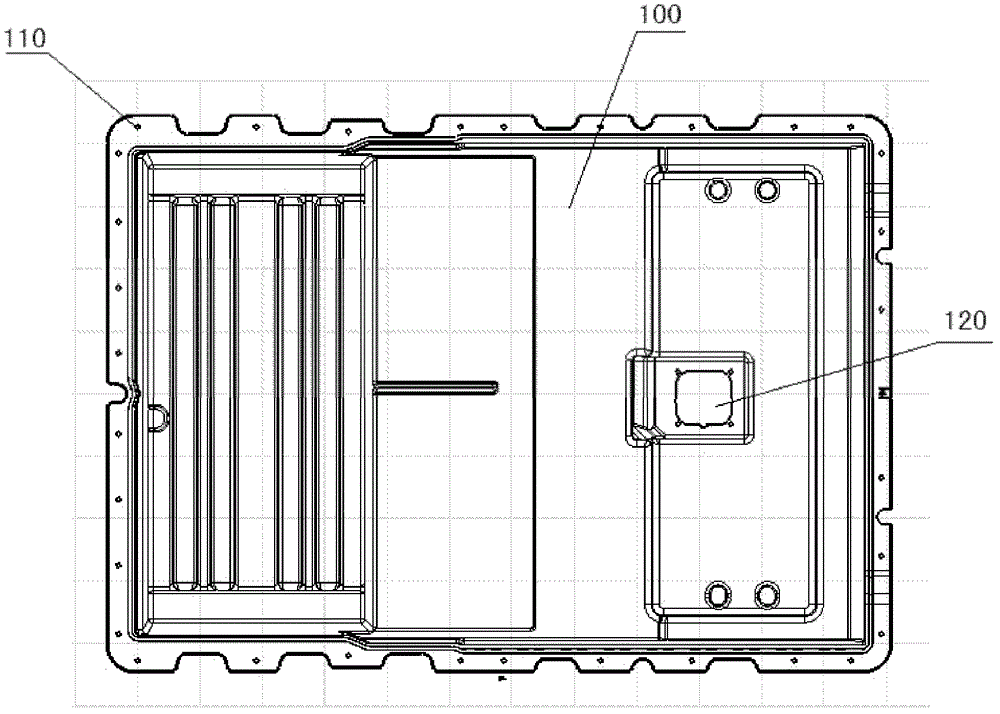

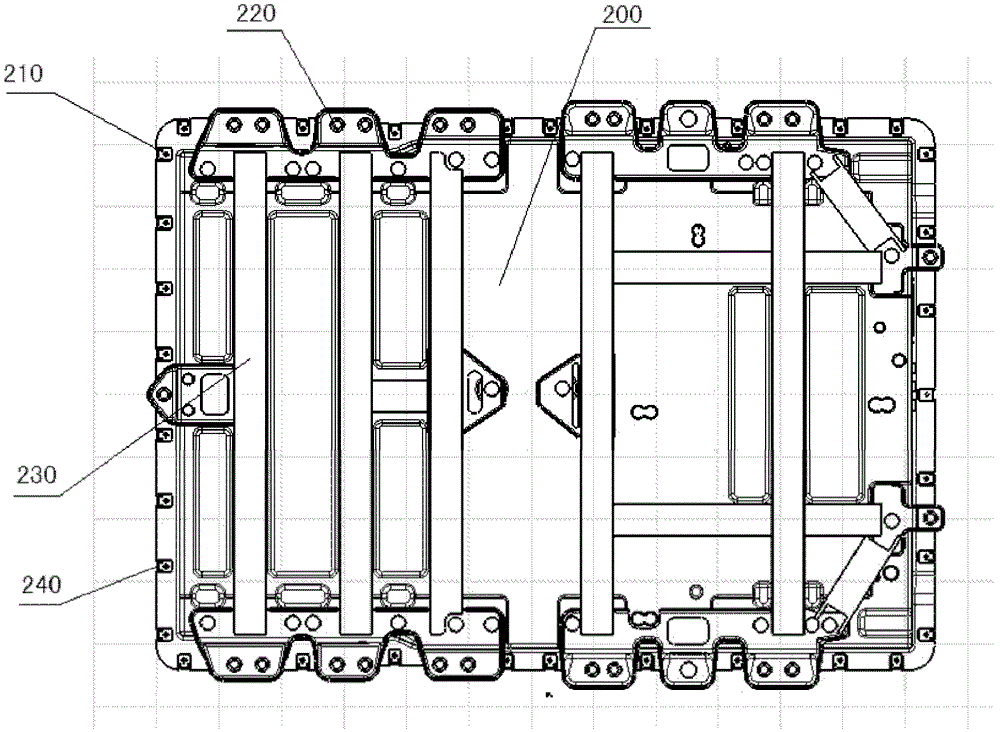

[0054] A method for manufacturing a battery box assembly for a pure electric vehicle, the battery box assembly is composed of a battery box upper cover assembly and a battery box tray assembly, after the battery is assembled, the battery box upper cover assembly is buckled on the battery tray ; Wherein the battery case upper cover assembly is prepared by the following steps:

[0055] 1. Compression step

[0056] Prepare the battery box cover forming mold for preparing the battery box cover, the battery box forming mold includes the battery box cover forming upper mold and the battery box cover forming lower mold, on the surface of the battery box cover forming upper mold and the battery box cover forming lower mold Spray the external release agent, and then lay the rectangular SMC raw material cut into 1200mmx600mm on the lower mold for forming the battery box cover. The weight of the paving material is 7.8kg, and the area of the paving material is 60% of the surface area of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com