On-line cleaning method of coke oven gas pipeline

A coke oven gas and pipeline technology, applied in the field of cleaning, can solve problems such as poor circulation, difficult transportation, unstable production of the gas purification system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

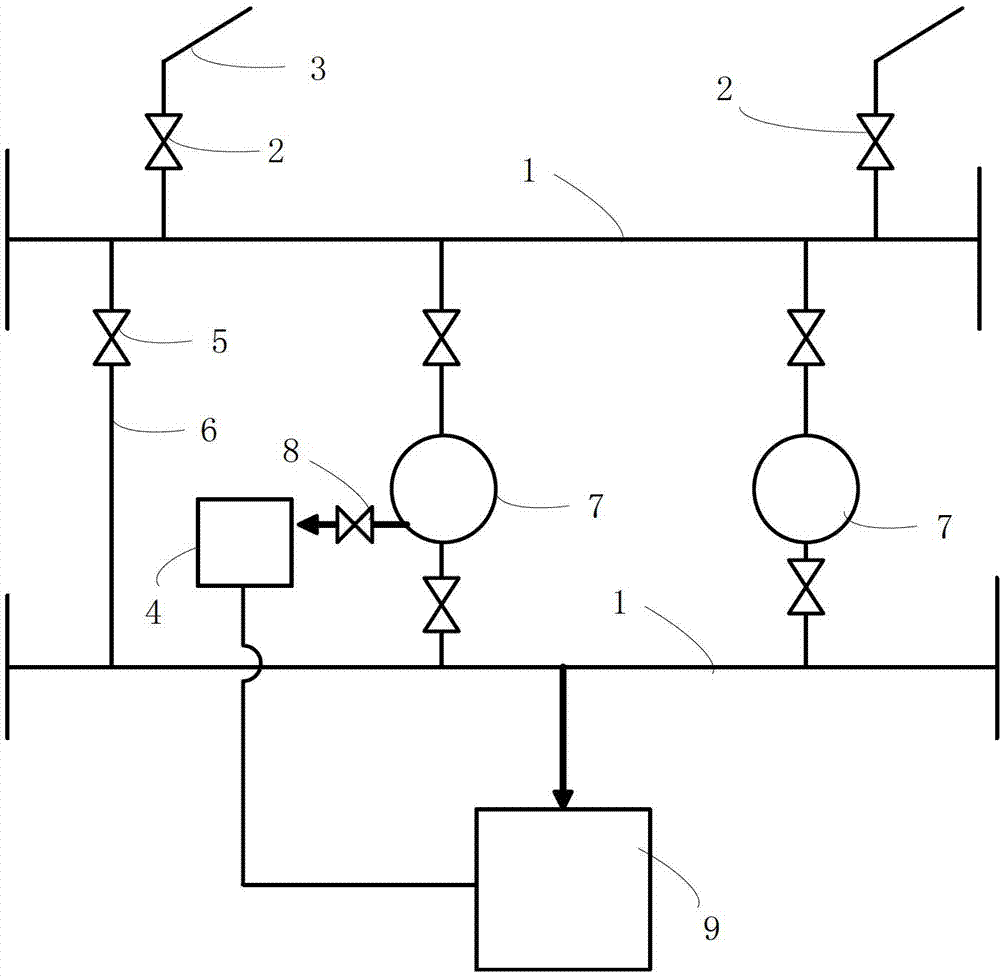

[0020] In order to overcome the deficiencies of steam purging technology, the present invention passes hot ammonia water into the coke oven gas pipeline through the improvement of coke oven gas online cleaning technology, and uses the principle of similar compatibility to remove impurities such as tar and naphthalene attached to the inner wall of the pipeline , Solve the problem of gas pipeline blockage.

[0021] Step 1: Set a temporary ammonia water pipeline valve on the temporary ammonia water pipeline, select a connection point on the coke oven gas pipeline, and connect the temporary ammonia water pipeline to the coke oven gas pipeline;

[0022] The connection point can be selected from the vent pipe, steam pipe, nitrogen pipe or instrument connection provided on the coke oven gas pipeline. When connecting, the temporary ammonia water pipeline can be connected to the release pipe, steam pipe, nitrogen pipe or instrument connection pipe set on the coke oven gas pipeline.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com