Method for controlling emptiness sound of bearing plate of prestressed post-tensioned box beam

A bearing plate and prestressing technology, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of bearing plate fasting sound, dense steel bars, and poor concrete penetration, so as to reduce later maintenance and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

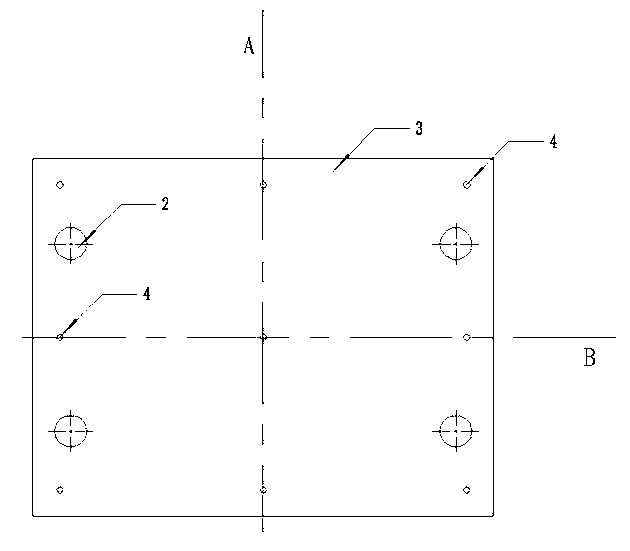

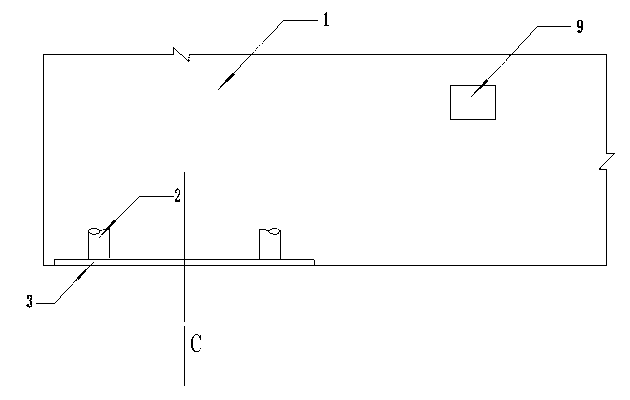

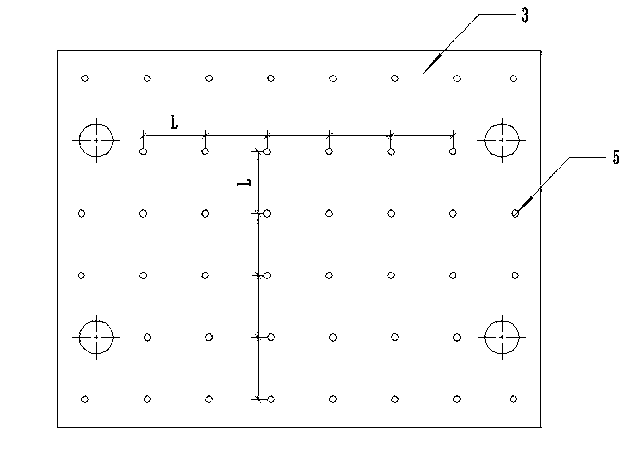

[0013] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0014] The method for controlling the fasting sound of the bearing slab of the prestressed post-tensioned box girder includes the steps of bonding stones on the inner surface of the bearing slab and the pouring sequence of concrete near the bearing slab.

[0015] (1) Bond stones on the inner surface of the support plate 3, the specific method is as follows: before the support plate 3 is installed, use steel glue to evenly bond the crushed stones with a particle size of 20-25mm on the surface of the embedded surface of the support plate 3 Stone 5 and crushed stone 5 are arranged at a distance L of 100-150mm. The bonding position of crushed stone 5 should avoid the mesh reinforcement of the beam body at the support. The bond of crushed stone 5 should be firm to ensure that the bonded gravel undisturbed.

[0016] (2) The pouring of concrete near the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com