Dog clutch for automated transmission

A technology for tooth clutches and automatic transmissions, applied in mechanical drive clutches, intermeshing clutches, clutches, etc., to solve problems such as prolonged shifting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

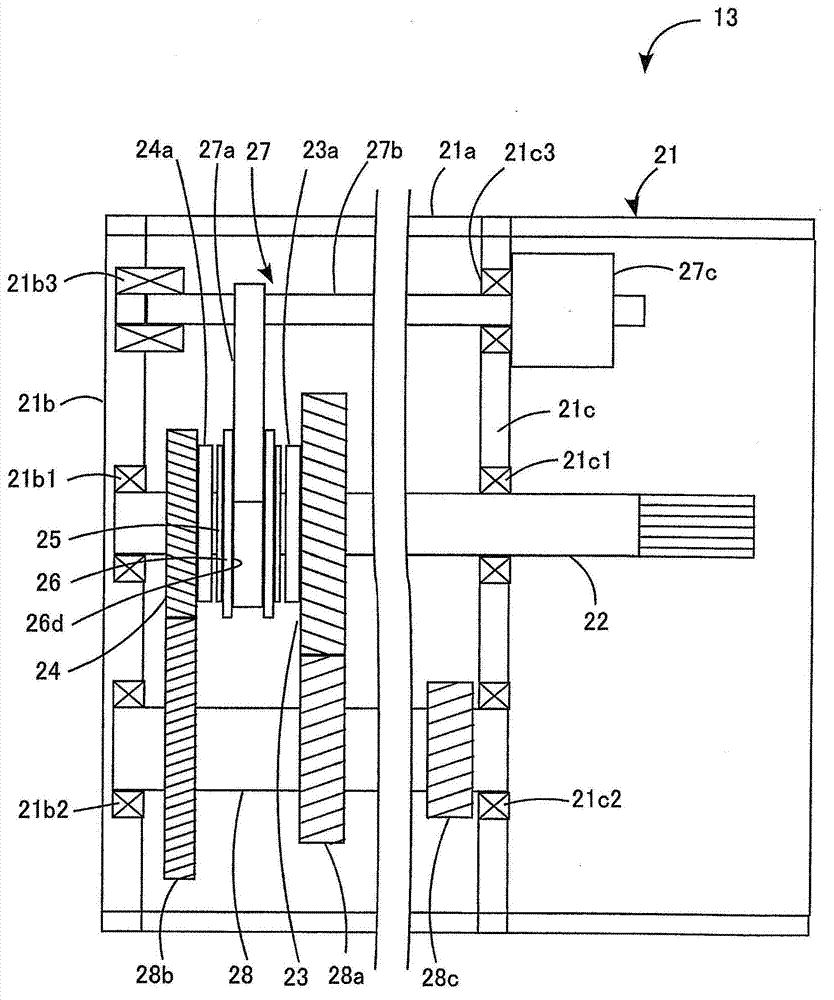

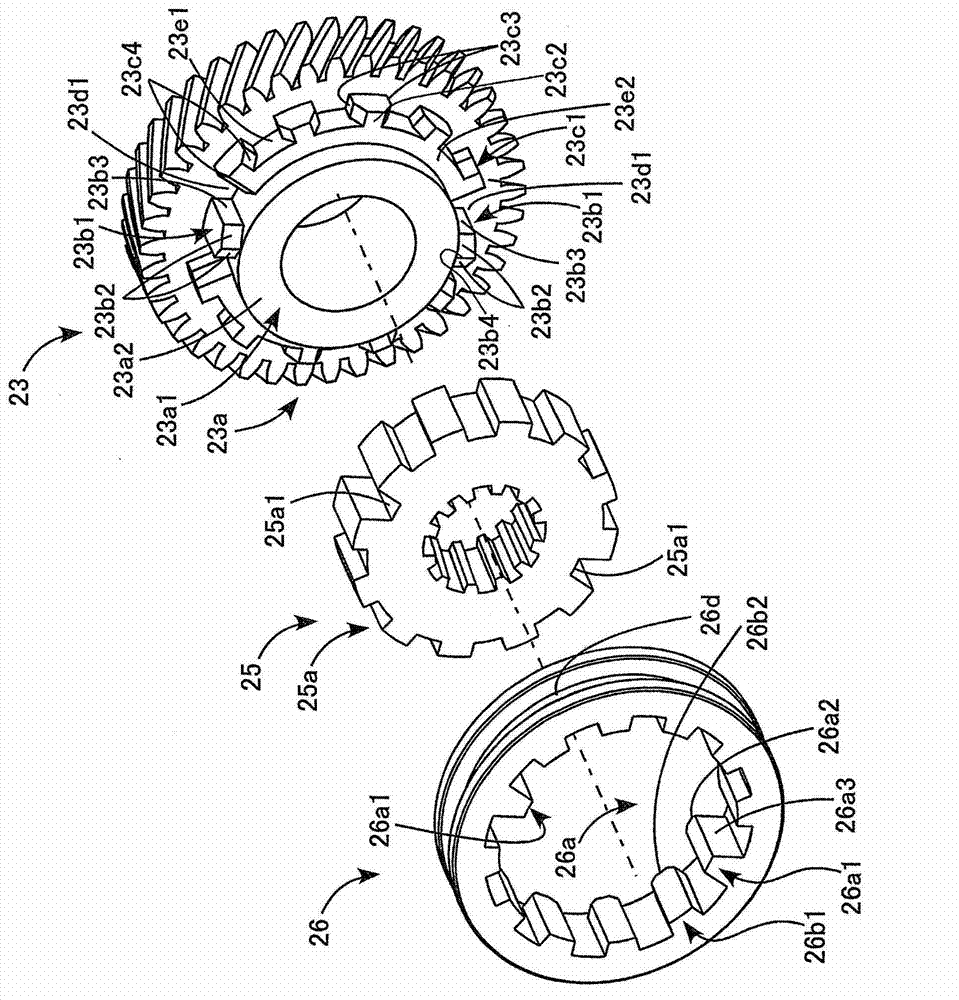

[0041] Hereinafter, a first embodiment of a dog clutch for an automatic transmission mounted to a vehicle will be described with reference to the drawings.

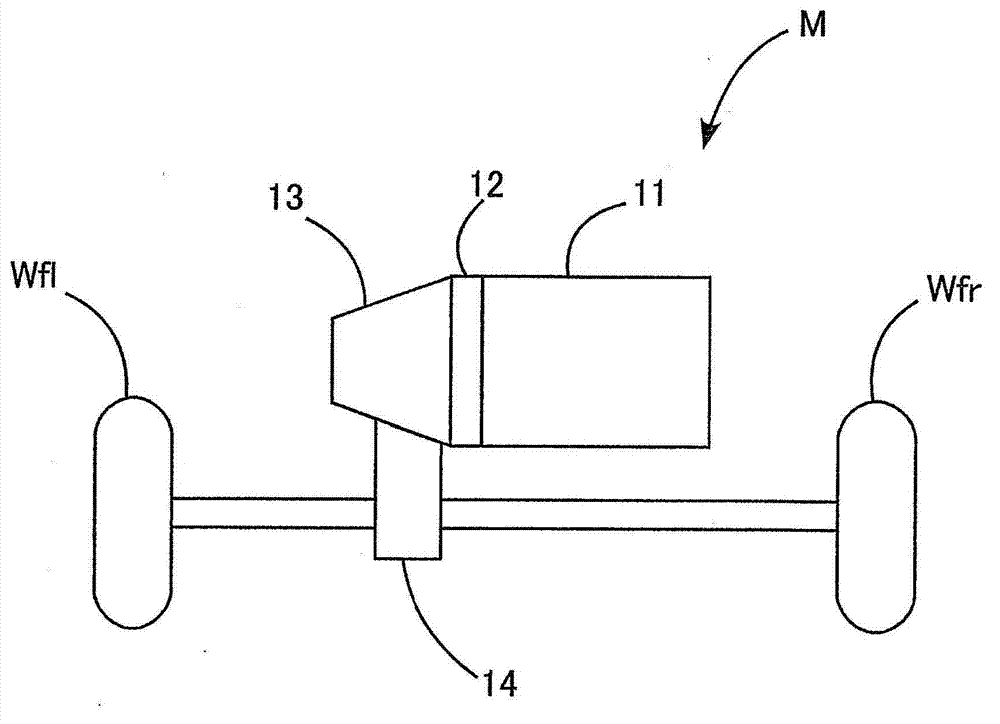

[0042] Such as figure 1 As shown, the vehicle M includes an engine 11, a clutch 12, an automatic transmission (for example, an automatic manual transmission) 13, a differential gear device 14 and driving wheels, specifically a left front driving wheel Wfl and a right front driving wheel Wfr. The engine 11 generates driving force by burning fuel. The engine 11 is configured to transmit driving force to the left front drive wheel Wfl and the right front drive wheel Wfr via the clutch 12, the automatic transmission 13, and the differential gear device 14. That is, the vehicle M is a front-wheel drive vehicle.

[0043] The clutch 12 is configured to be automatically connected or disconnected based on instructions from the control device. The automatic transmission 13 includes a dog clutch mechanism to automatically select, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com