Filter valve

A filter valve and filter tube technology, applied in the directions of filtration and separation, valve device, mechanical equipment, etc., can solve the problems of unsatisfactory filtering effect and insufficient practical value, and achieve the effect of high practical value, convenient cleaning or replacement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

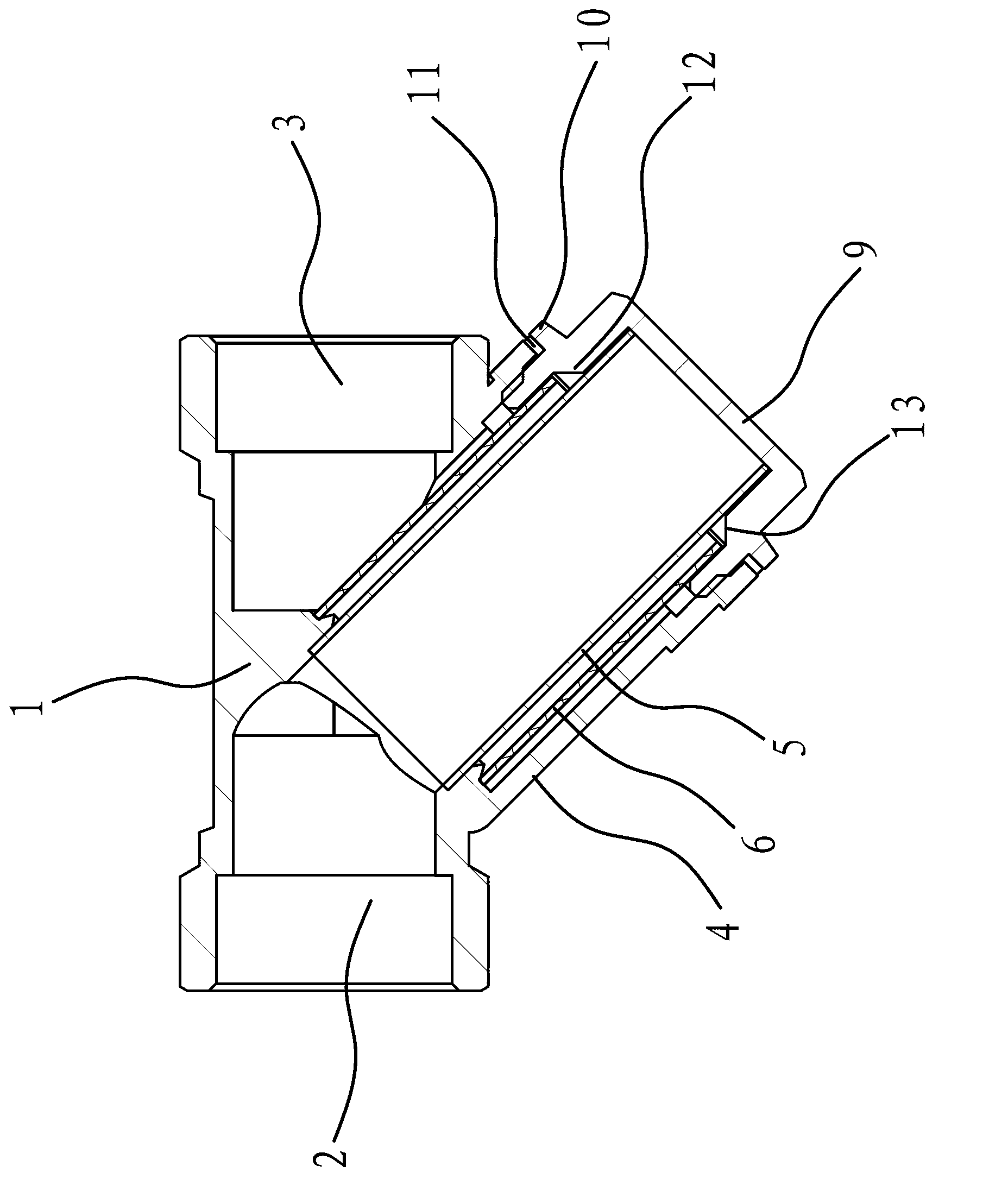

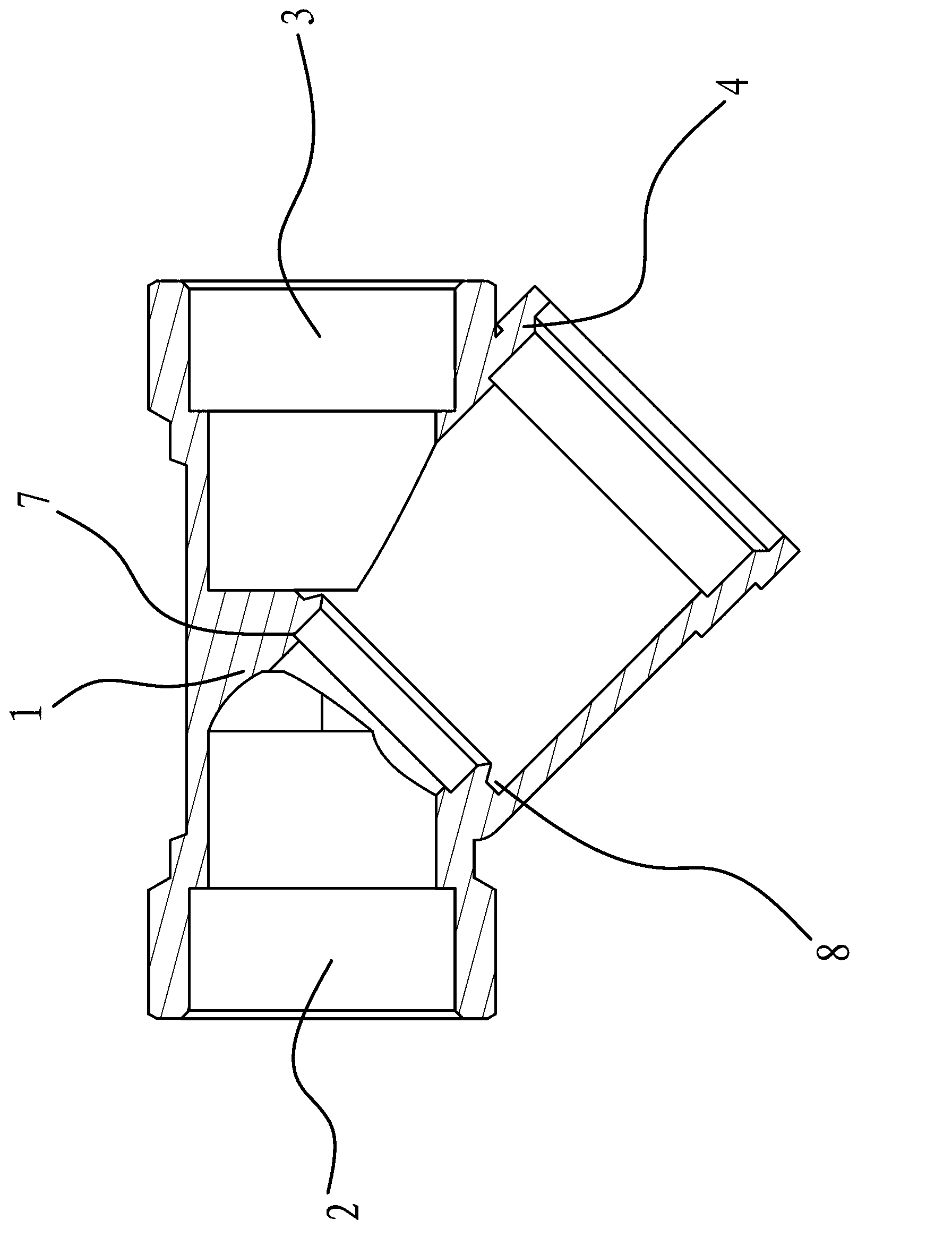

[0026] like figure 1 and figure 2 As shown, a filter valve includes a valve body 1 with two ends respectively being a water inlet 2 and a water outlet 3, and a filter tube 4 is also provided on the valve body 1, and the water outlet 3 and the water inlet 2 of the valve body 1 pass through the filter The tubes 4 communicate with each other, the filter tube 4 is inclined relative to the valve body 1 and the filter tube 4 and the valve body 1 are in an integrated structure.

[0027] The filter pipe 4 is fixed with a coarse filter screen 5 and a fine filter screen 6, the coarse filter screen 5 is set outside the fine filter screen 6, the coarse filter screen 5 and the fine filter screen 6 are in a regular grid shape and the thickness of the coarse filter screen 5 The meshes are larger than the meshes of the fine filter screen 6 . The valve body 1 has a positioning seat 7 at the inner port of the filter tube 4, the inner end of the coarse filter screen 5 leans against the positi...

Embodiment 2

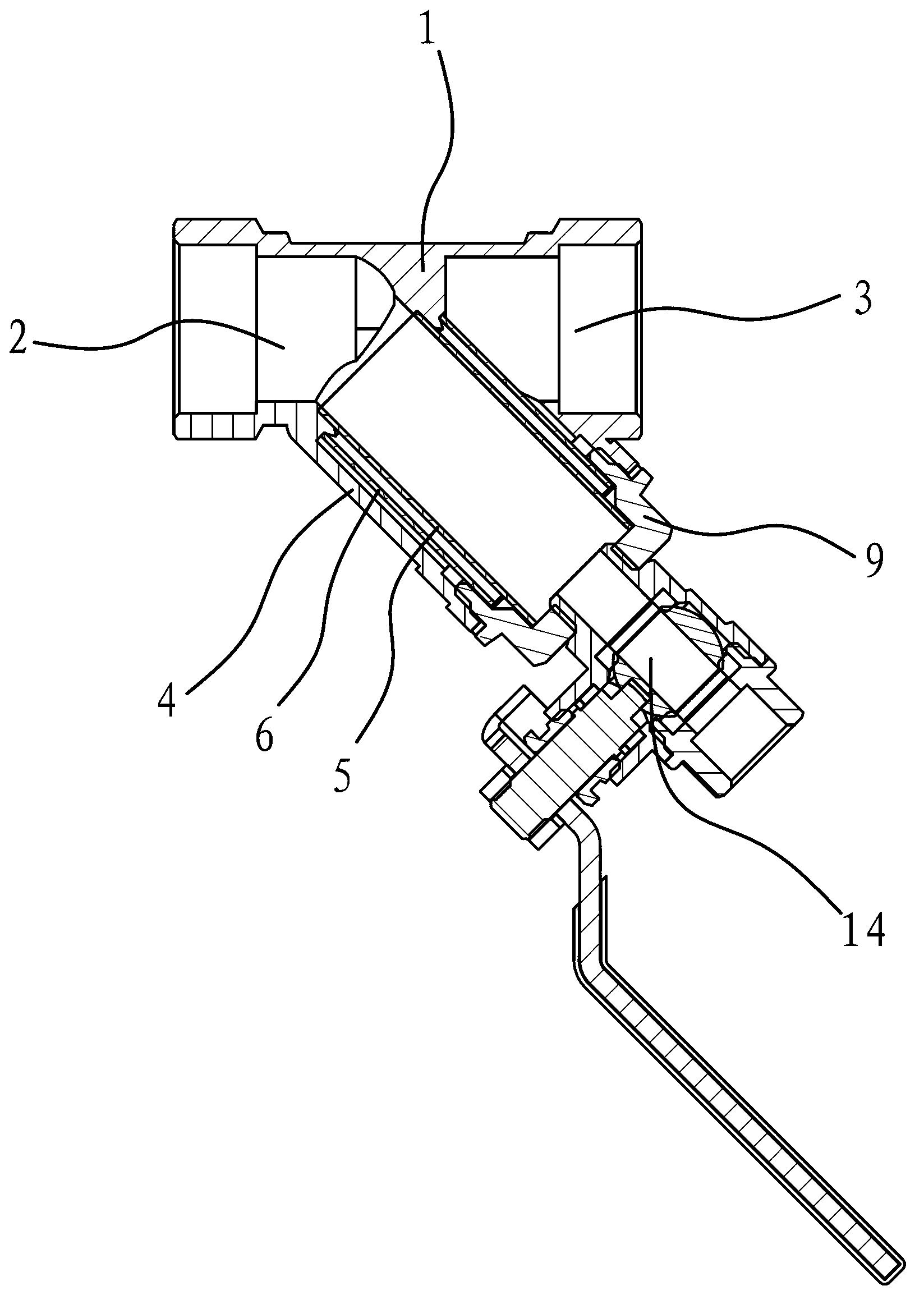

[0032] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: image 3 As shown, the blowdown member in this embodiment also includes a blowdown valve 14 that is threadedly connected with the gland 9 , and the blowdown valve 14 is a ball valve and communicates with the filter pipe 4 . By setting a blowdown valve 14 connected with the filter pipe 4, when the impurities in the filter pipe 4 accumulate more, it is not necessary to unscrew the gland 9, and the blowdown can be carried out quickly only by opening the blowdown. Close the drain valve 14 and get final product. Of course, when cleaning or replacing the filter screen, the drain valve 14 needs to be unscrewed together with the gland 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com