End covers of LED (Light Emitting Diode) tubular lamp and LED tubular lamp

An LED tube lamp and end cap technology, applied in the field of LED lighting, can solve the problems of inconsistent length, poor quality, and high rejection rate of LED lamps, and achieve the effects of safe and reliable work performance, simple and reasonable structure, and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

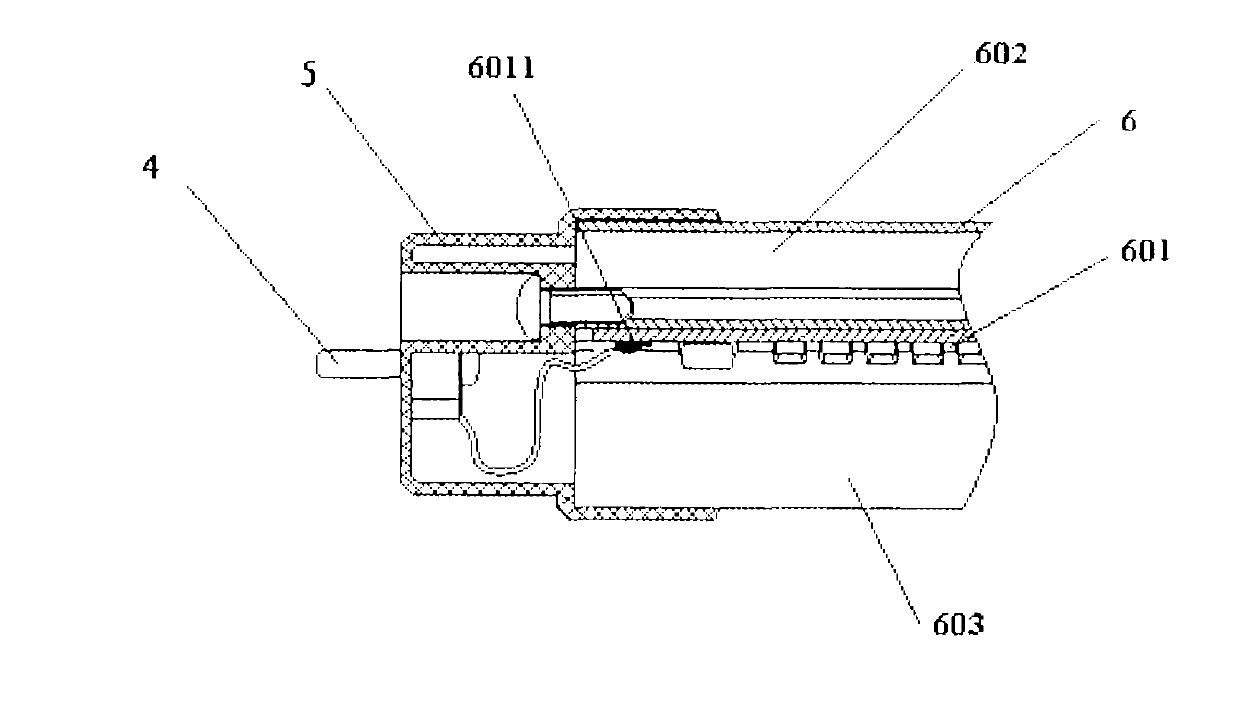

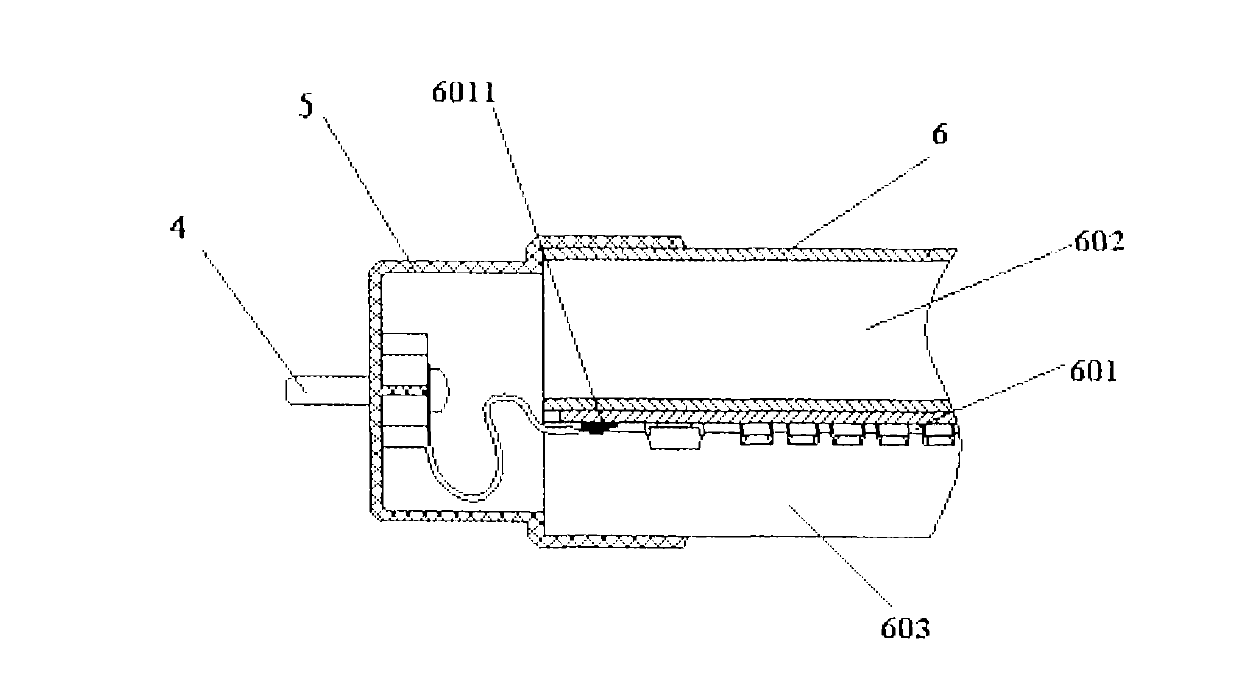

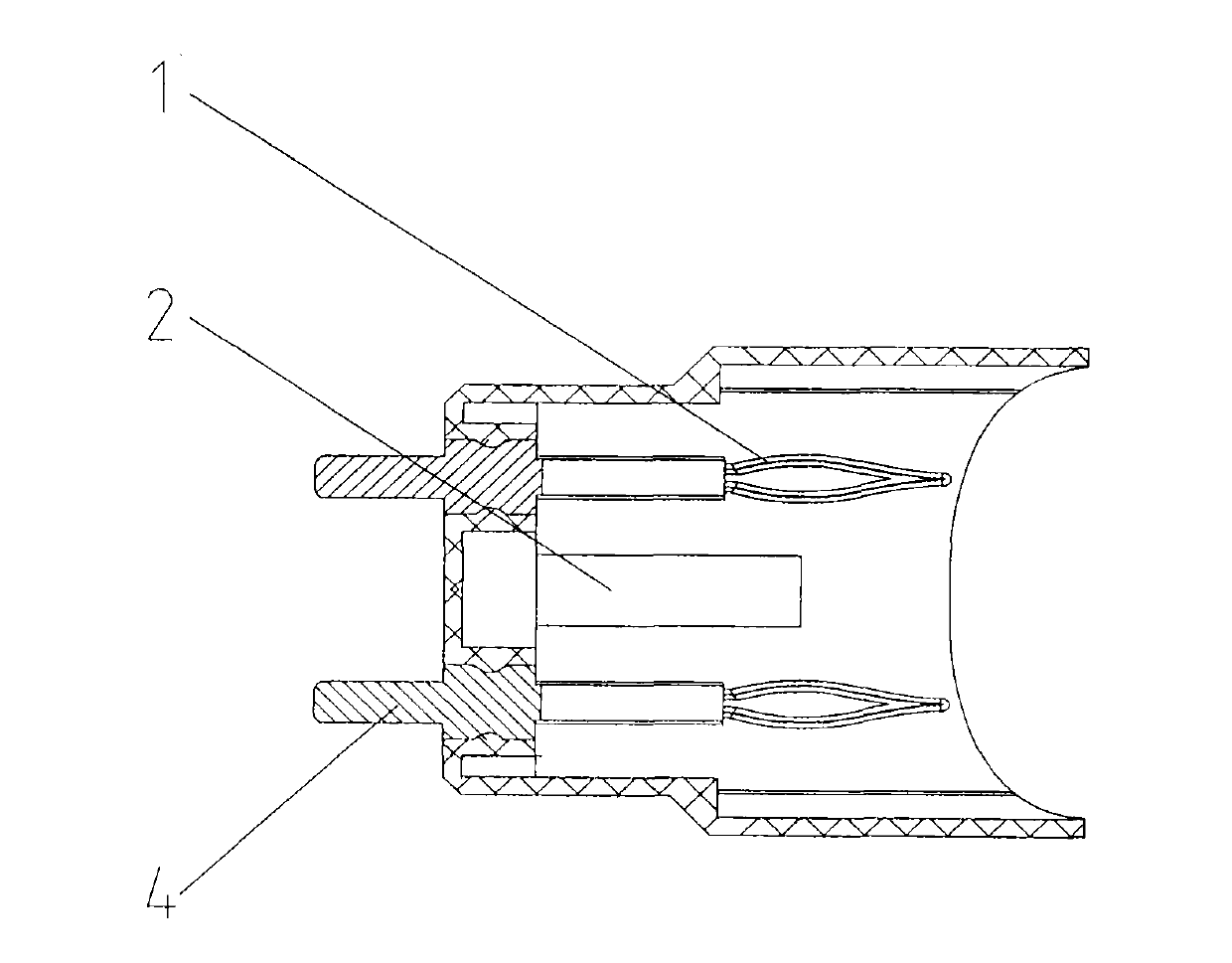

[0038] Figure 2A It is a sectional view of the end cover of the LED tube lamp of the present invention; Figure 2B It is the perspective view 1 of the end cap of the LED tube lamp of the present invention; Figure 2C It is the second perspective view of the end cap of the LED tube lamp of the present invention.

[0039] The end cap 5 for the LED tube lamp in this embodiment includes a terminal post 4, an elastic conductive cylinder 1, a buckle 2, and an end cap main body 501. The end cap 5 is in the shape of a straight rotary shell and is made of engineering plastics. Specifically, materials such as nylon, polycarbonate, and ABS can be selected. Two terminal posts 4 are fixedly installed on the bottom wall of the end cover 5 to provide a power supply circuit for the LED tube lamp. There is an annular boss 502 on the side wall of the end cover 5 close to the middle of its axial length. The open end is an arc structure, which facilitates the installation and cooperation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com