Energy-saving ground heating floor

A floor heating and floor technology is applied in the field of floor boards with energy-saving effect, which can solve the problems of wood waste and excessive wood consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

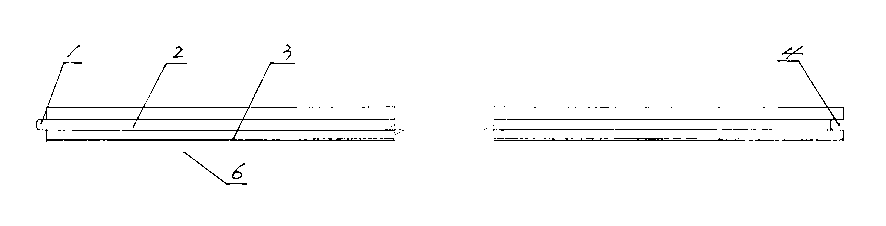

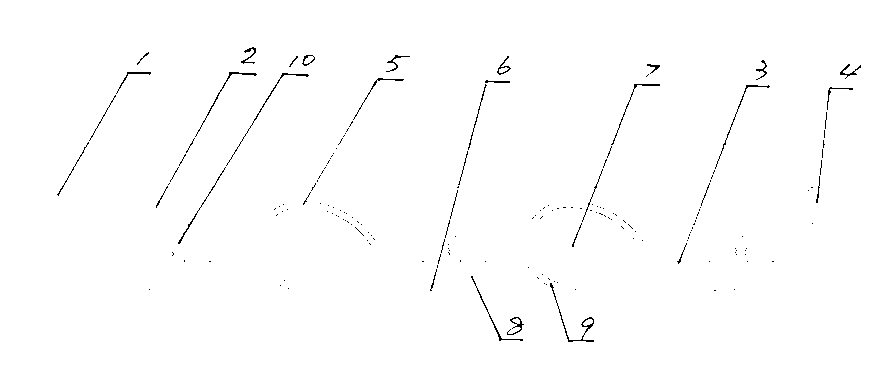

[0023] like figure 1 , figure 2 As shown, the energy-saving floor heating floor of the present invention includes a floor board 2, and the floor board 2 is any one of a solid wood floor board, a multi-layer composite floor board or a high-density floor board, and the floor board 2 in this embodiment is a solid wood board floor boards. The longitudinal two sides of the floor board 2 are respectively processed with a longitudinal rib 1 and a first longitudinal groove 4, and the longitudinal rib 1 and the first longitudinal groove 4 are both located in the middle of the thickness direction of the side of the corresponding side. . During laying, among two adjacent floorboards 2 : the longitudinal rib 1 on one floorboard 2 is embedded in the first longitudinal groove 4 on the other floorboard 2 . Two second longitudinal grooves are processed on the lower surface of the floor board 2 . A composite layer 3 is provided on the lower surface of the floor board 2, and the composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com