Heat pump system

A heat pump system, outdoor heat exchanger technology, applied in lighting and heating equipment, compressors with reversible cycles, damage protection, etc., can solve problems such as reduced comfort, long defrost time, temperature drop, etc. The effect of reducing, improving system operation efficiency, and maintaining stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

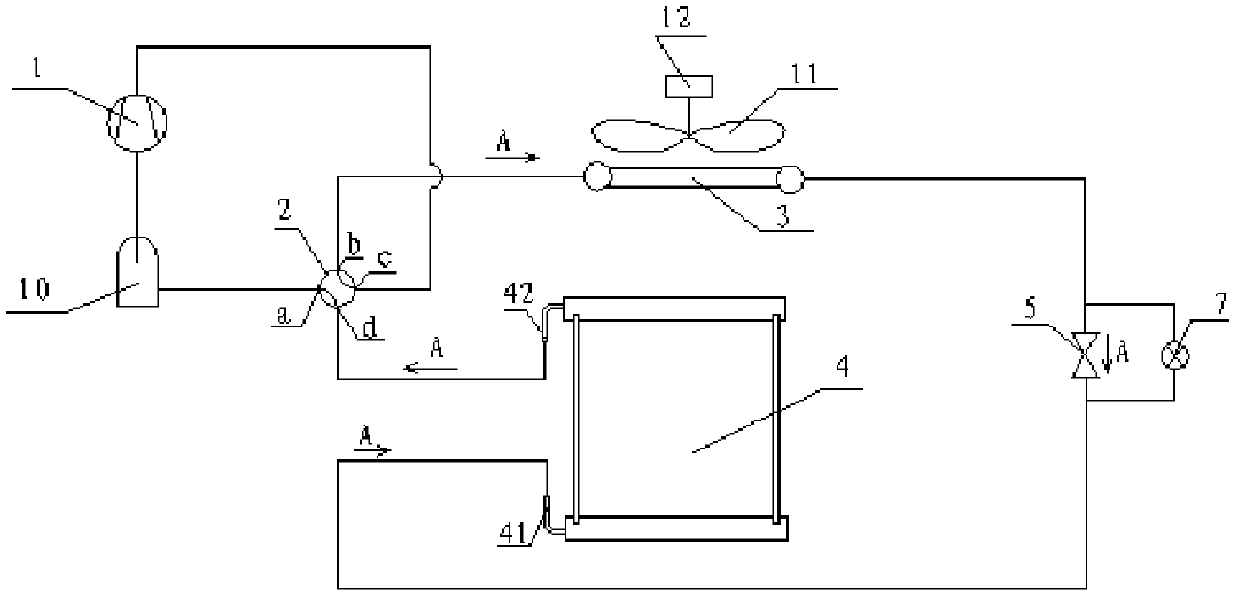

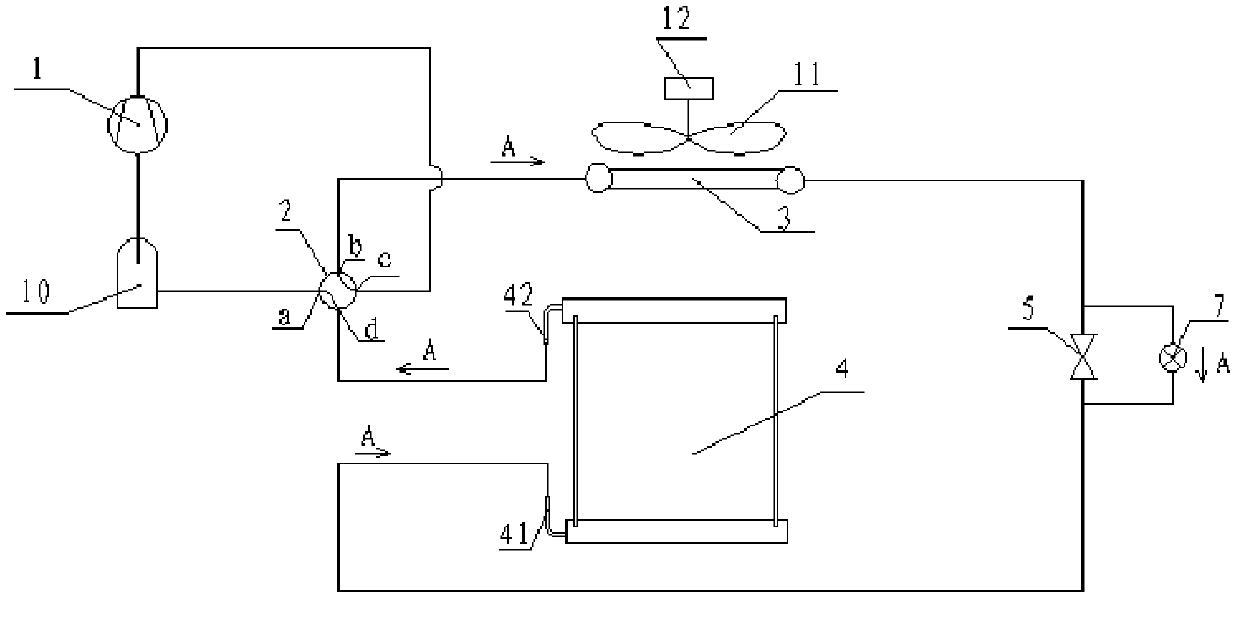

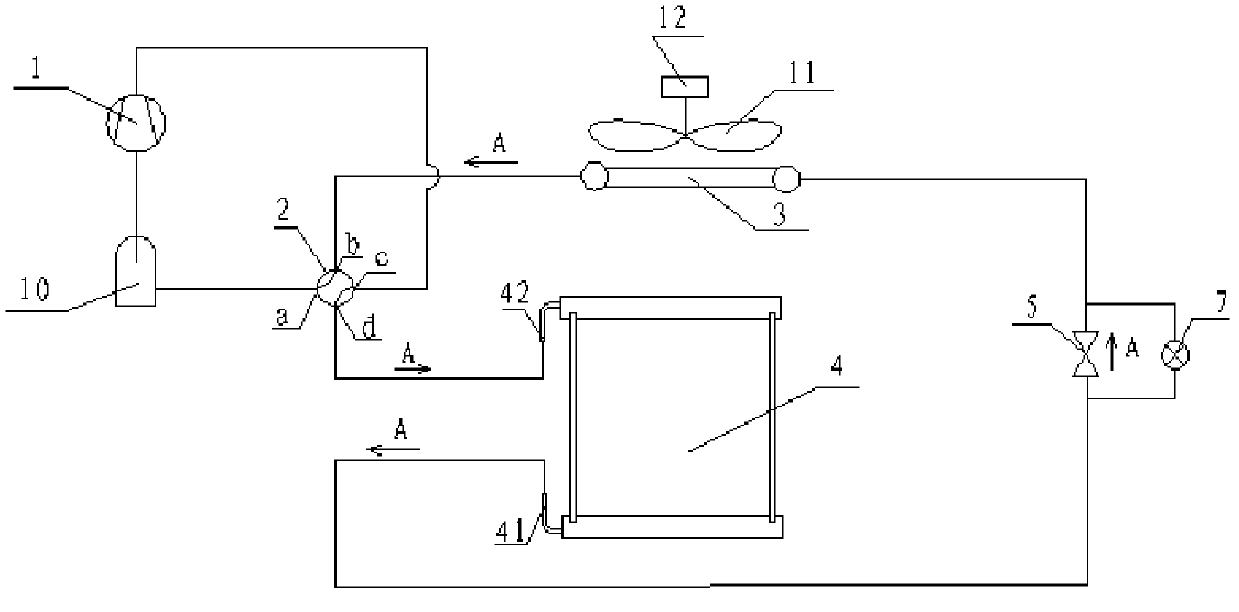

[0022] Refer below Figure 1-3 A heat pump system according to a first embodiment of the present invention is described.

[0023] Such as Figure 1-3 As shown, the heat pump system according to the embodiment of the present invention includes a compressor 1, a gas-liquid separator 10, a four-way valve 2, an indoor heat exchanger 3, an outdoor heat exchanger 4, a first throttling mechanism 5 and a first bypass valve 7.

[0024] Specifically, the four-way valve 2 has first to fourth valve ports a, b, c and d, and the outlet and inlet of the compressor 1 are respectively connected with the third valve port c and the first valve port a of the four-way valve 2, The gas-liquid separator 10 is connected in series between the inlet of the compressor 1 and the first valve port a. Each of the indoor heat exchanger 3 and the outdoor heat exchanger 4 has first and second openings, the first opening of the indoor heat exchanger 3 is connected to the second valve port b of the four-way v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com