Method and system for determining infrared data sampling time

A technology of sampling time and infrared data, which is applied in the field of infrared positioning, can solve the problems of reducing the positioning accuracy and sensitivity of infrared touch screens, and the inability to judge touch events, etc., and achieve the effects of improving positioning accuracy and sensitivity, wide application range, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

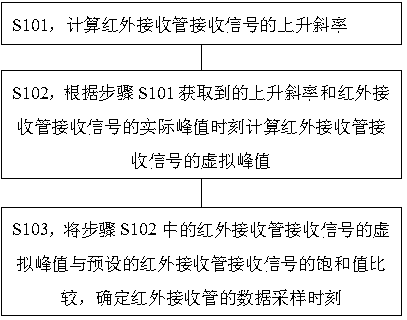

[0027] Such as figure 1 Shown is a flow chart of a specific embodiment of a method for determining an infrared data sampling time according to the present invention. see figure 1 , a kind of infrared data sampling moment determination method of the present specific embodiment comprises the following steps:

[0028] S101, calculate the rising slope of the received signal of the infrared receiving tube; wherein, when the infrared receiving tube receives the signal, a series of received signals will be obtained, and there is an upward trend or a downward trend between the received signal values, by calculating the received signal in the upward trend The slope formed between the values is taken as the rising slope.

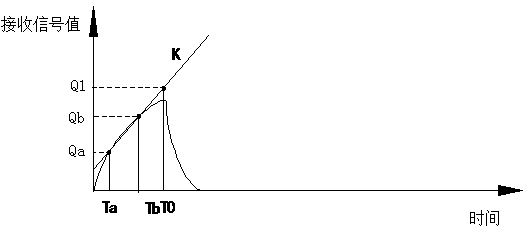

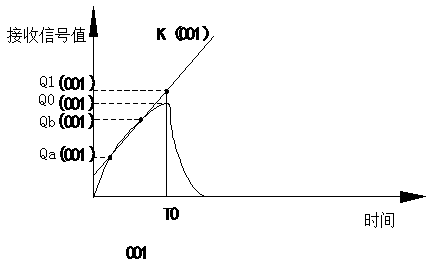

[0029] S102, calculate the virtual peak value of the signal received by the infrared receiving tube according to the rising slope obtained in step S101 and the actual peak time of the signal received by the infrared receiving tube; there is a peak sampling time in...

Embodiment 2

[0047] Such as Figure 5 As shown, it is a schematic diagram of the result of a specific embodiment of the infrared data sampling time determination system of the present invention. see Figure 5 , the infrared data sampling time determination system of this specific embodiment specifically includes:

[0048] The slope acquisition module 11 is used to calculate the rising slope of the curve corresponding to the upward trend of the infrared receiving tube receiving signal value; wherein, when the infrared receiving tube receives the signal, a series of receiving signals can be obtained, and there is an upward trend between the receiving signal values. For a downward trend, the slope acquisition module 11 calculates the slope formed between the received signal values in an upward trend as the upward slope.

[0049] The peak calculation module 12 is used to calculate the virtual peak value of the signal received by the infrared receiving tube according to the obtained rising ...

Embodiment approach

[0055] As a preferred implementation, the data sampling moment determination module 13 includes:

[0056] The difference acquisition module is used to make a difference between the virtual peak value of the infrared receiving tube receiving signal and the preset saturation value of the infrared receiving tube receiving signal; wherein, the saturation value of the infrared receiving tube receiving signal is obtained by the difference acquiring module in advance Setting, it can be set as the maximum working voltage parameter of the infrared receiving tube, the maximum working voltage parameter can be queried from the specifications or instructions of the infrared receiving tube, or can be set according to the actual situation, such as in a preferred In the method, in the no-touch state, the received signal value of the infrared receiving tube read at the actual peak time is taken as the saturation value of the infrared receiving tube.

[0057] The result judging module is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com