Optimum design method used for cross beam structure of numerical control machine tool and employing extreme dimension adjustment

A technology of optimized design and numerically controlled machine tools, applied in computing, electrical digital data processing, special data processing applications, etc., to achieve the effect of wide application and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

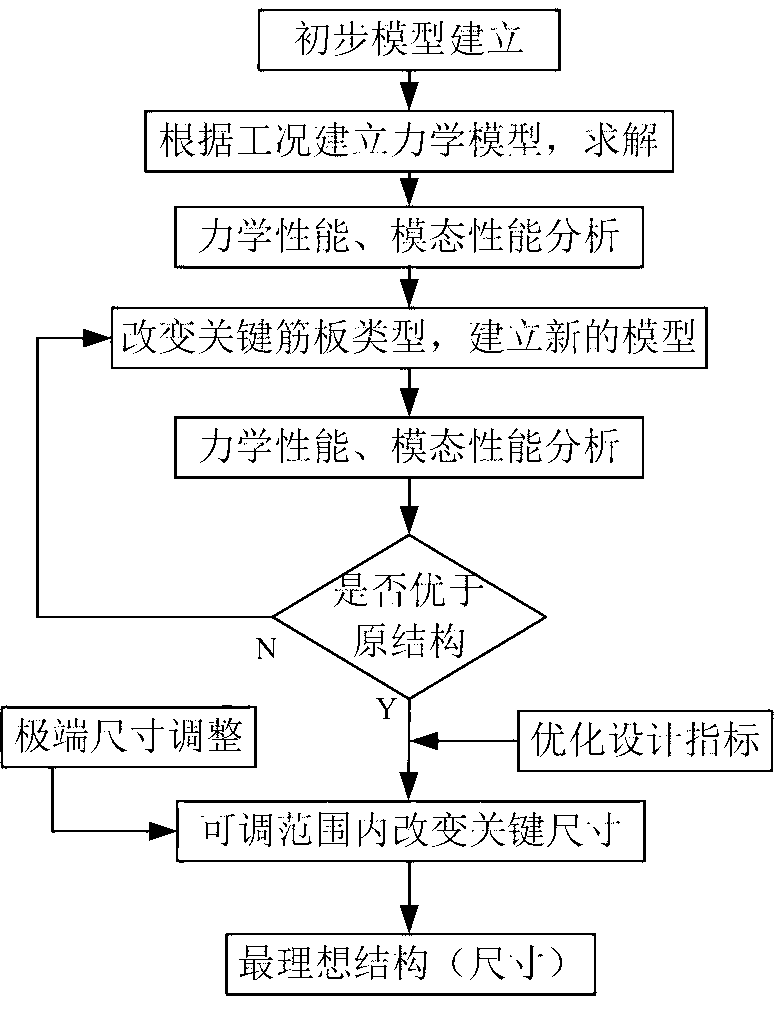

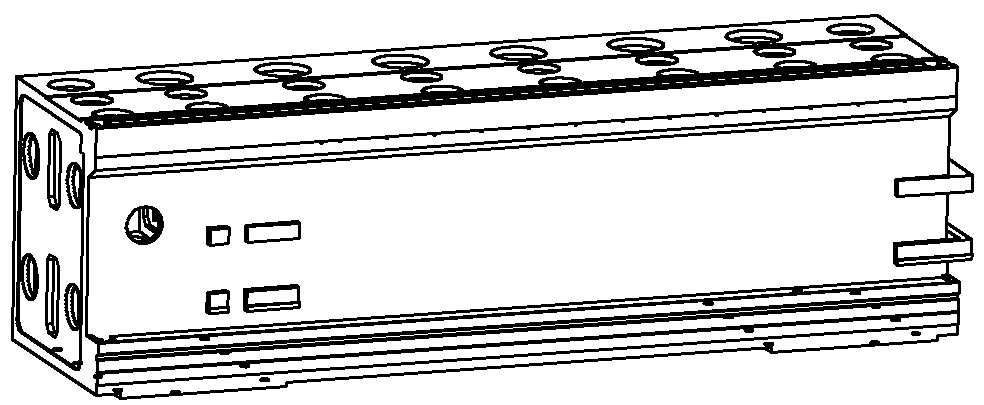

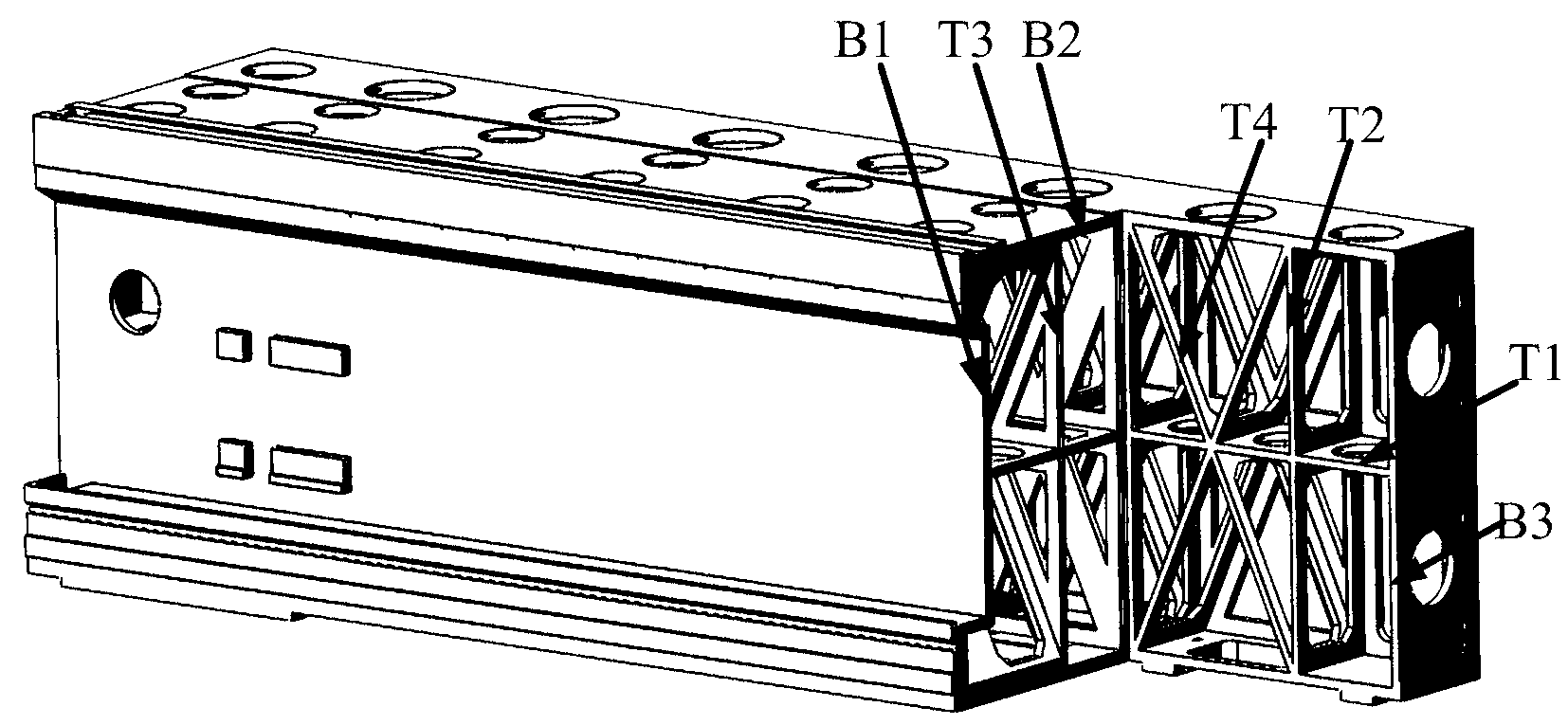

[0021] The present invention mainly optimizes from two aspects: the type of ribs inside the beam structure and the adjustment of the thickness of the key dimensions of the beam structure. The specific optimization design process is as follows: figure 1 shown. Firstly, the three-dimensional model of the beam structure is preliminarily established, and the mechanical model of the beam structure is established according to the working conditions, and the calculated actual force of the beam structure is used as the load to analyze the static and dynamic mechanical properties; by changing the type of internal ribs, several new models are designed. Analyze the mechanical properties of the beam structure scheme, select the optimal rib plate distribution type in the scheme that is better than the original structure, and determine the beam structure scheme; finally, conduct sensitivity analysis on the key dimensions of the beam structure, and set one or more The performance index to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com