A column bearing assembly structure

A technology for assembling structures and column bearings, which is applied in structural connections, electromechanical devices, casings/covers/supports, etc., can solve the problems of increased bearing capacity, inability to meet the needs of large loads, and increased number of bearings, etc., to achieve The effect of increasing bearing capacity, preventing bearing burnout failure, and eliminating assembly defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

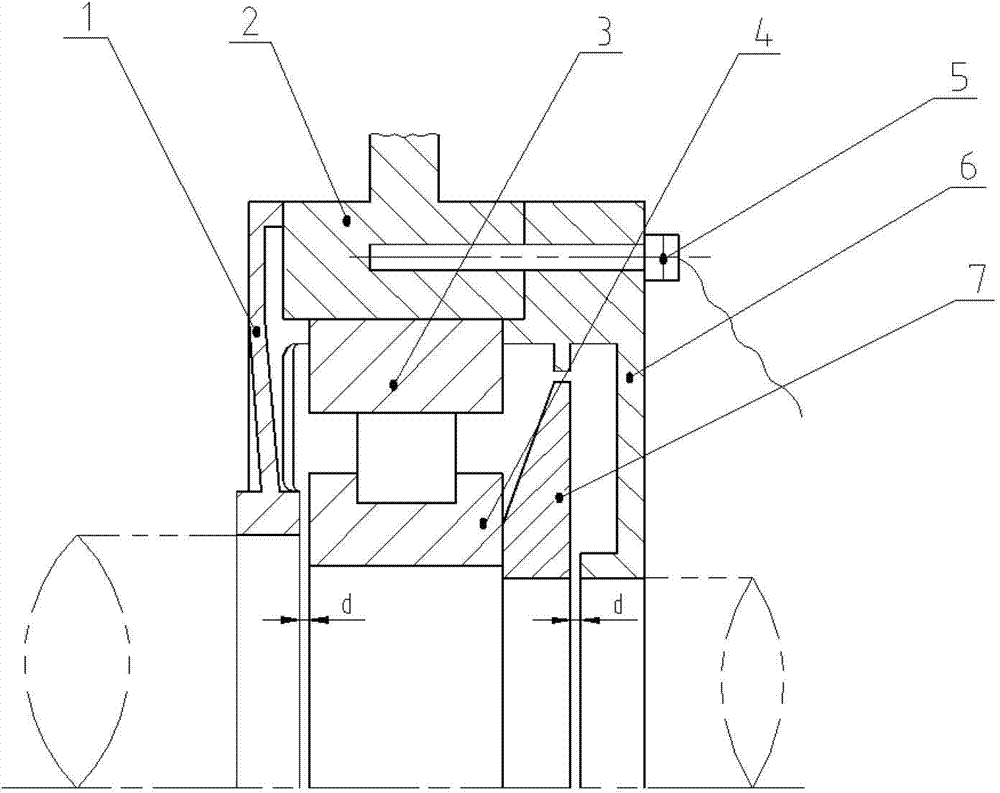

[0008] As shown in the accompanying drawings, a specific embodiment of the column bearing assembly structure of the present invention includes a bearing inner cover (1), a bearing sleeve (2), a bearing outer ring (3), a bearing inner ring (4), a temperature sensor ( 5), bearing cover (6), oil deflector ring (7).

[0009] The radial position and axial position of the bearing outer ring (3) are respectively fixed by the bearing sleeve (2), the bearing inner cover (1) and the bearing outer cover (6). The bearing inner ring (4) is set on the motor shaft Since the inner and outer rings of the column bearing can move axially, the oil deflector ring (7) and the bearing inner ring (4) are close together, and the oil deflector ring (7) and the bearing outer cover ( 6) and between the inner cover of the bearing (1) and the inner ring of the bearing (4), there must be a gap d, so that an axially movable space is created between the inner and outer rings of the bearing. When both ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com