Battery selecting method

A screening method and battery technology, applied in sorting and other directions, can solve problems such as the screening of different single cells, and achieve the effect of improving battery life and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail, but the present invention is not limited to the scope of the described embodiments.

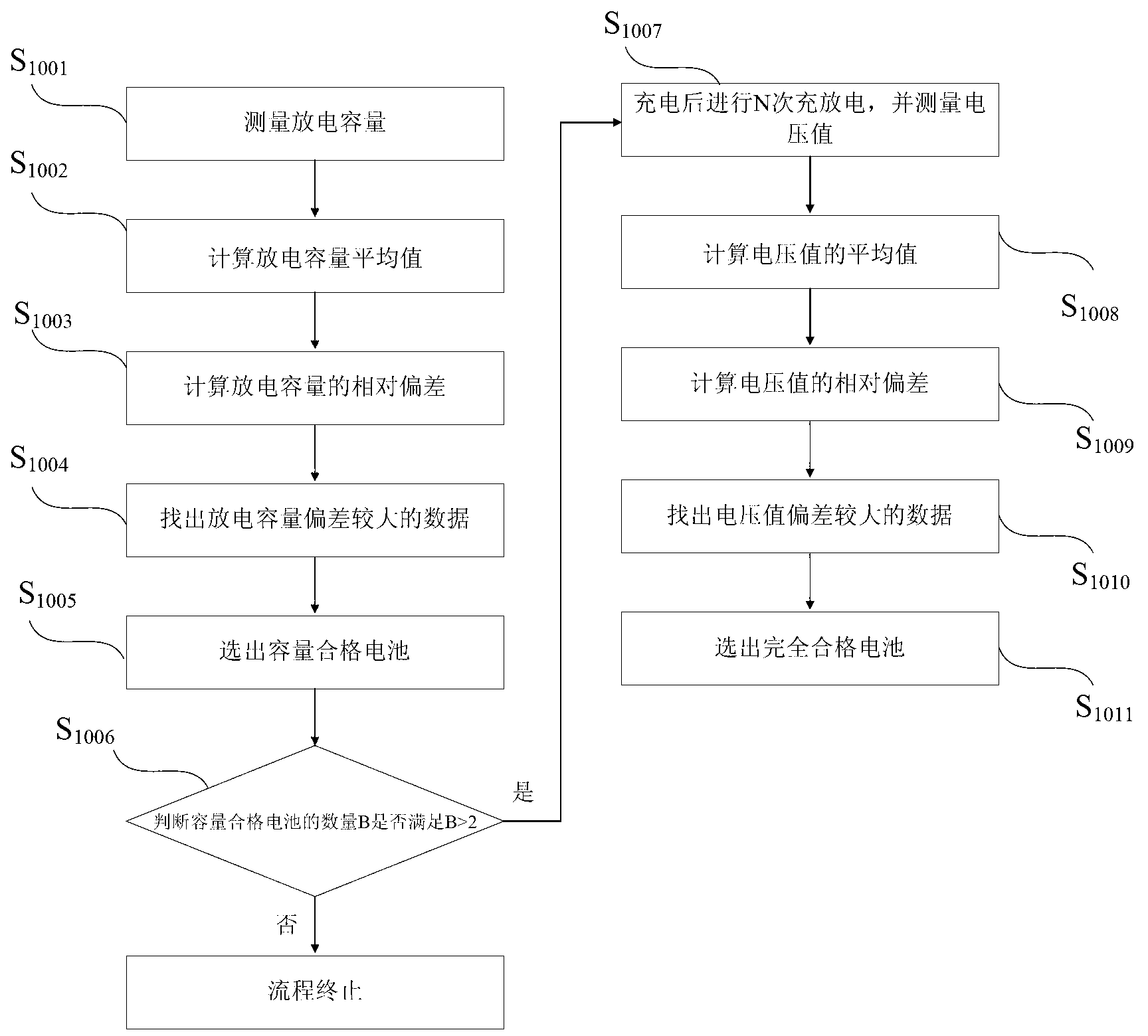

[0038] Such as figure 1 As shown, the battery screening method of a preferred embodiment of the present invention comprises the following steps:

[0039] S 1001 1. Carry out M complete charge-discharge cycles for A battery respectively, measure and record the discharge capacity of each battery in each complete charge-discharge cycle, and record the discharge capacity of the a-th battery at the m-th complete charge-discharge cycle as H am , where A>2, M>0, and a traverses the integers satisfying 0<aA, and m traverses the integers satisfying 0<mM;

[0040] S 1002 , Calculate the average value of the discharge capacity of the A battery in the mth full charge and discharge cycle as H m ;

[0041] S 1003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com