Wear-resistant stamping die

A stamping die and stamping forming technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor surface quality of the die and easy occurrence of high temperature oxidation, so as to reduce the replacement frequency, enhance the wear resistance, improve the The effect of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

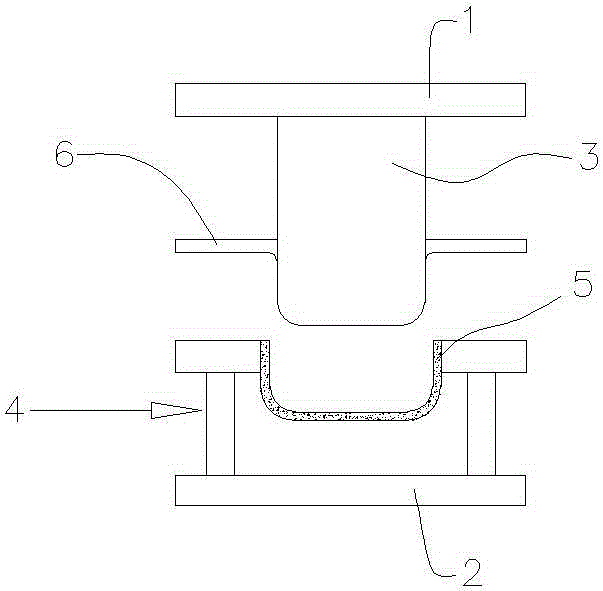

[0011] The wear-resistant stamping die of the present embodiment is as figure 1 As shown, it includes an upper mold base 1 and a lower mold base 2 arranged oppositely, the upper mold base 1 is provided with a punch 3 , and the lower mold base 2 is provided with a die 4 . The punch 3 is provided with a pressing plate 6 for pressing the edge of the formed part, and the surface of the die 4 is uniformly covered with ceramic particles 5, and the surface of the ceramic particles 5 is evenly coated with a resin layer (not shown in the figure).

[0012] In this embodiment, the ceramic particles 5 are glued to the surface of the die 4 .

[0013] In the wear-resistant stamping die of this embodiment, ceramic particles 5 are evenly and densely distributed on the surface of the die 4, and the excellent wear resistance of the ceramic particles 5 is used to greatly enhance the wear resistance of the mold, and the surface of the ceramic particles 5 is evenly coated with The resin layer can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com