Moving mechanism for core box trolley of core-making machine

A technology of moving mechanism and movement box, which is applied in the direction of core, molding machine, manufacturing tools, etc. It can solve the problems of short service life of rollers and guide rails, complex overall structure, and roller detachment from guide rails, etc., achieving high reliability and simple overall structure , the effect of uniform wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

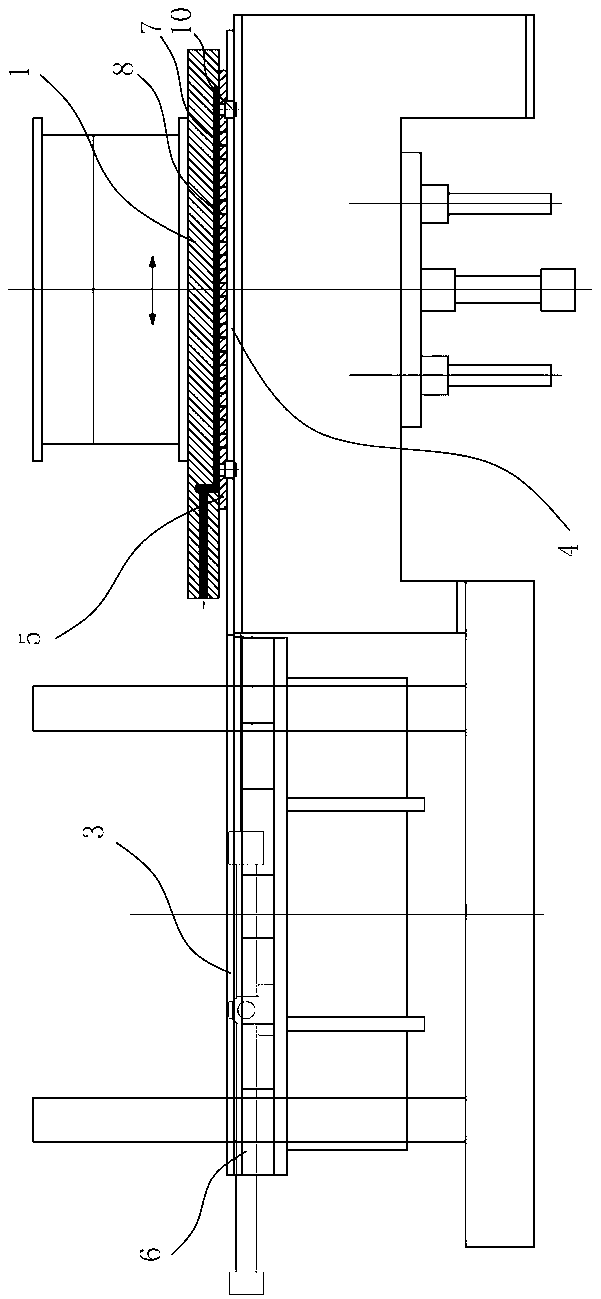

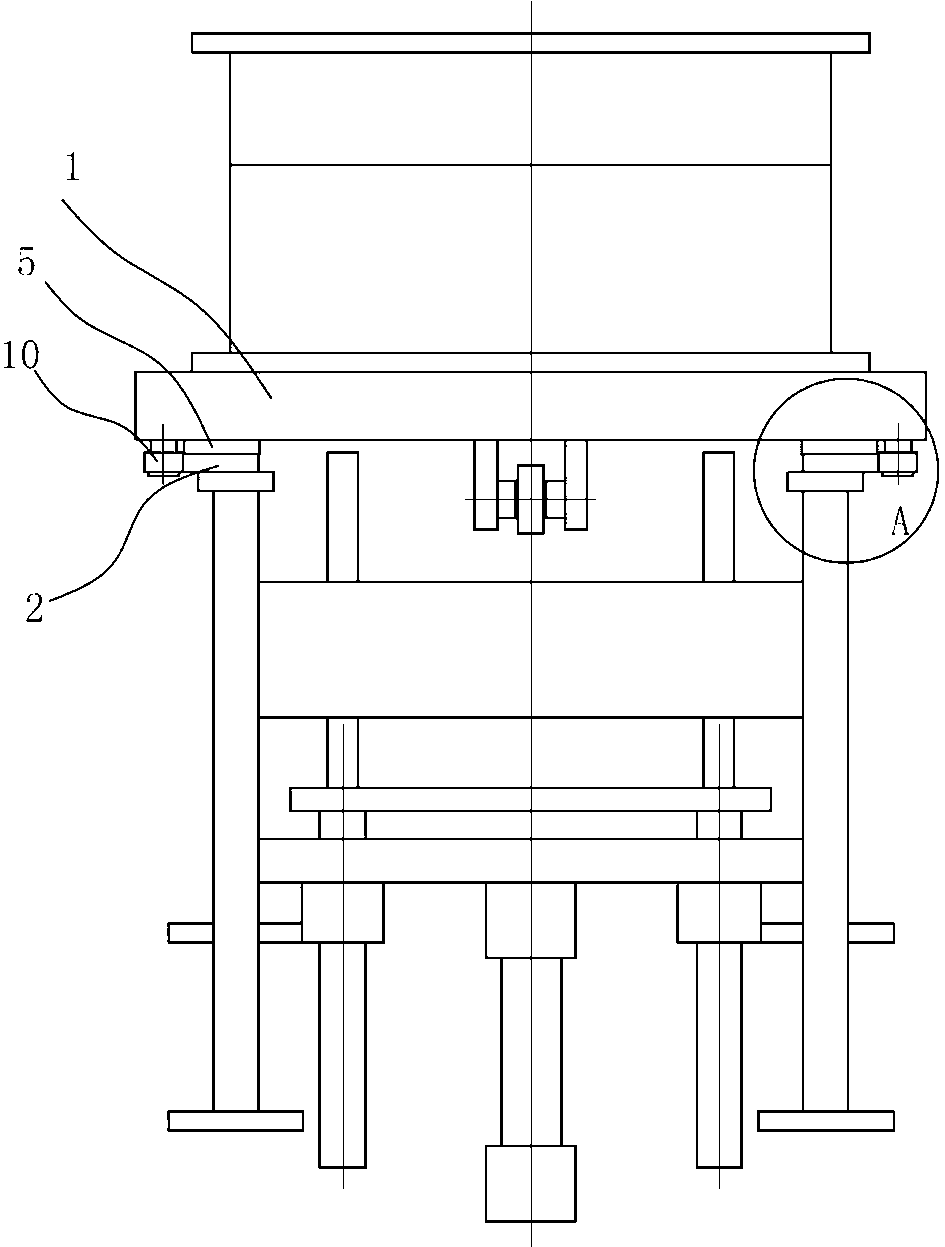

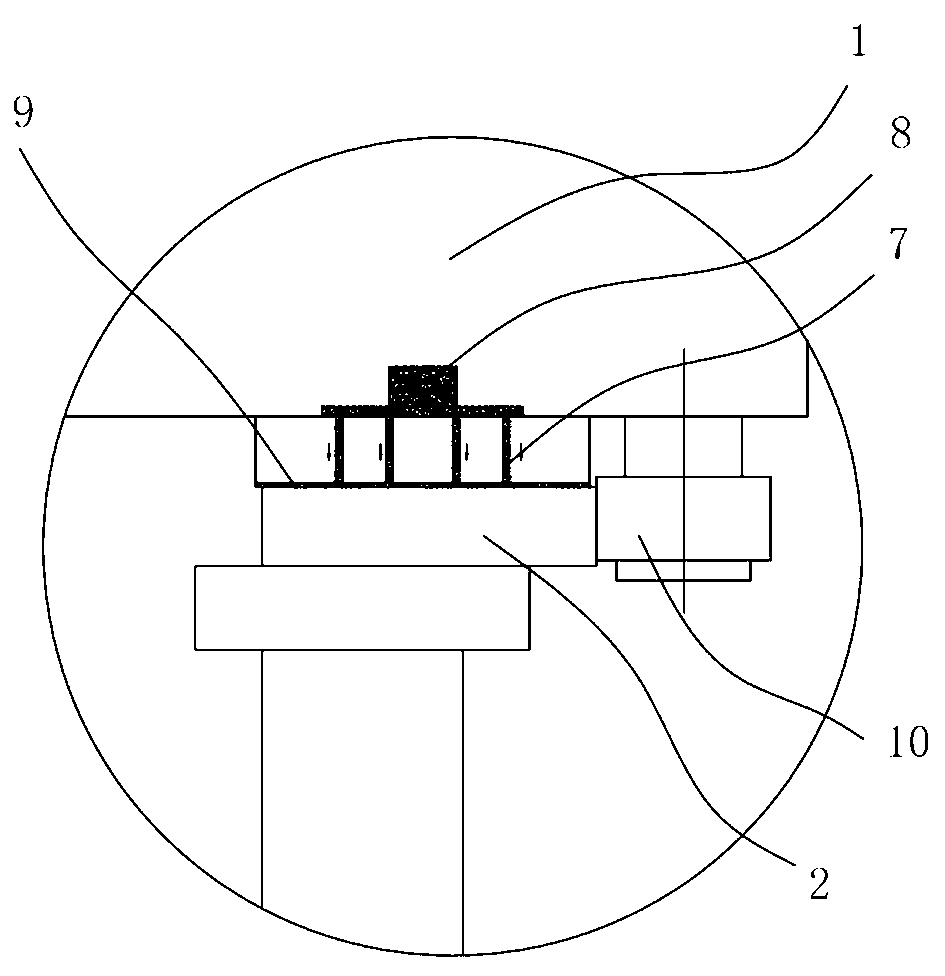

[0028] Embodiment one: see attached figure 1 to attach image 3 As shown, a core box trolley moving mechanism includes a core box trolley 1, a pair of guide rails 2 arranged in parallel, a driving structure and a guide structure, and the guide rails are composed of a workbench guide rail 3 and a lower top core guide rail 4. , the bottom of the core box trolley 1 is fixedly connected with a pair of support plates 5, a plurality of air holes 7 are distributed on the support plate 5, an air cavity 8 is provided at the bottom of the core box trolley, and the bottom of the air cavity 8 is connected to the support plate The air hole 7 on the top is connected, and one end of the air chamber 8 is connected to the compressed air source through the air pipeline. In the air pipeline, there is a lubricator, and the lubricator has a device for atomizing liquid oil and mixing it with compressed air. Structure; the lower surface of the support plate 5 is a plane, which is matched with the p...

Embodiment 2

[0031] Embodiment 2: A moving mechanism for a core box trolley, comprising a core box trolley 1, a pair of guide rails 2 arranged in parallel, a drive structure 3 and a guide structure 4, the guide rails are composed of a workbench guide rail 3 and a lower core guide rail 4 connection structure, the bottom of the core box trolley 1 is fixedly connected with a pair of support plates 5; the lower surface of the support plate 5 is a plane, which is matched with the workbench guide rail 3 or the lower top core guide rail 4 plane, and the workbench guide rail 3 or the upper surface of the lower top core guide rail 4 is distributed with a plurality of air holes 7, the guide rail is provided with an air cavity 8 communicating with the air holes, one end of the air cavity 8 is connected to a compressed air source through an air pipeline; the core box trolley 1 moves , there is an air cushion layer 9 between the lower surface of the support plate 5 and the guide rail 3 of the workbench ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com