Assembling device for decorative rings and shells of lamps of automobiles

A technology for automobile lamps and assembling devices, which is applied to workpiece clamping devices, manufacturing tools, metal processing, etc., can solve the problems of reducing the yield of lamp assembly, reducing production efficiency, increasing labor intensity, etc., so as to reduce auxiliary loading and unloading time, improve The effect of assembly quality and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

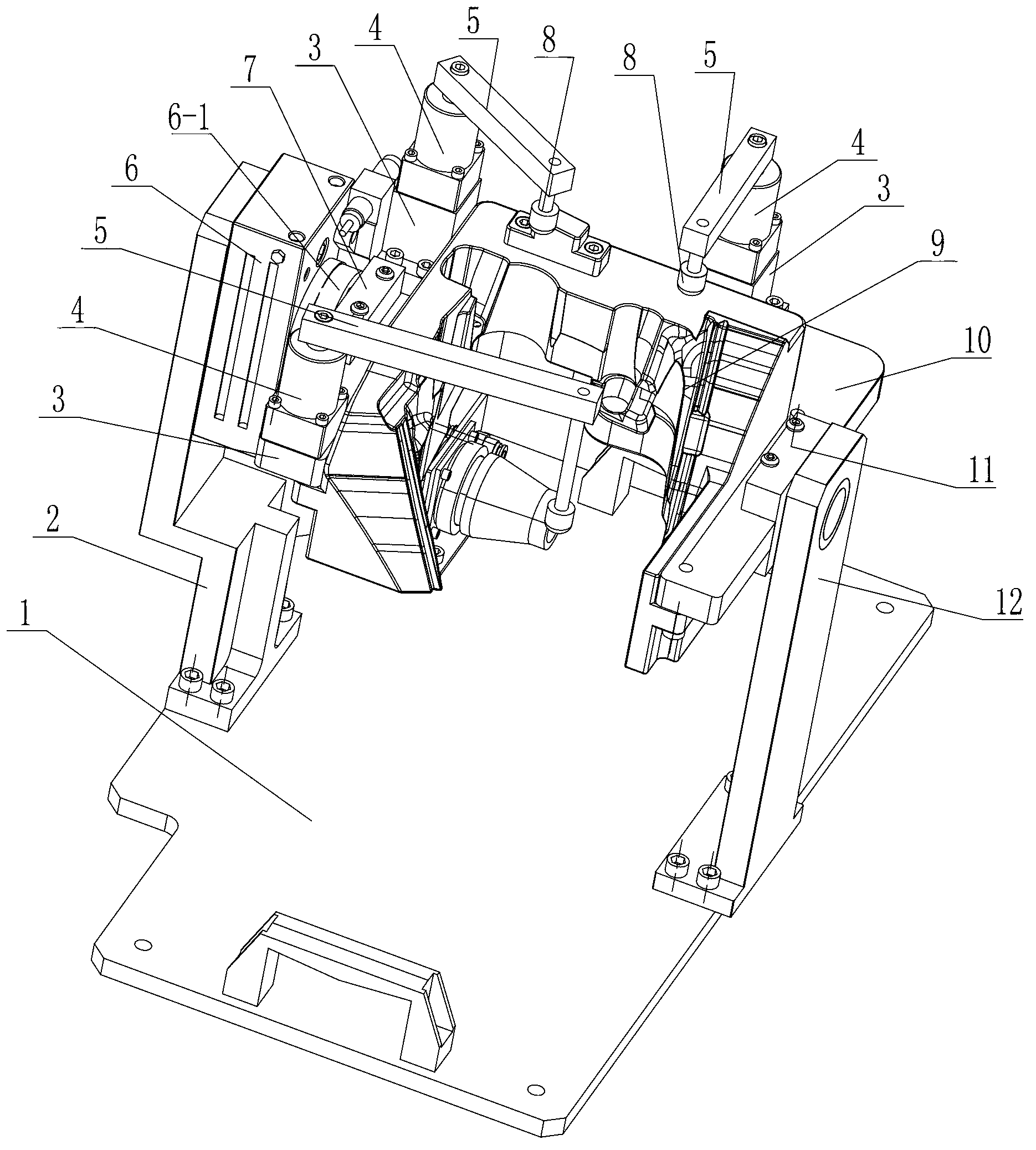

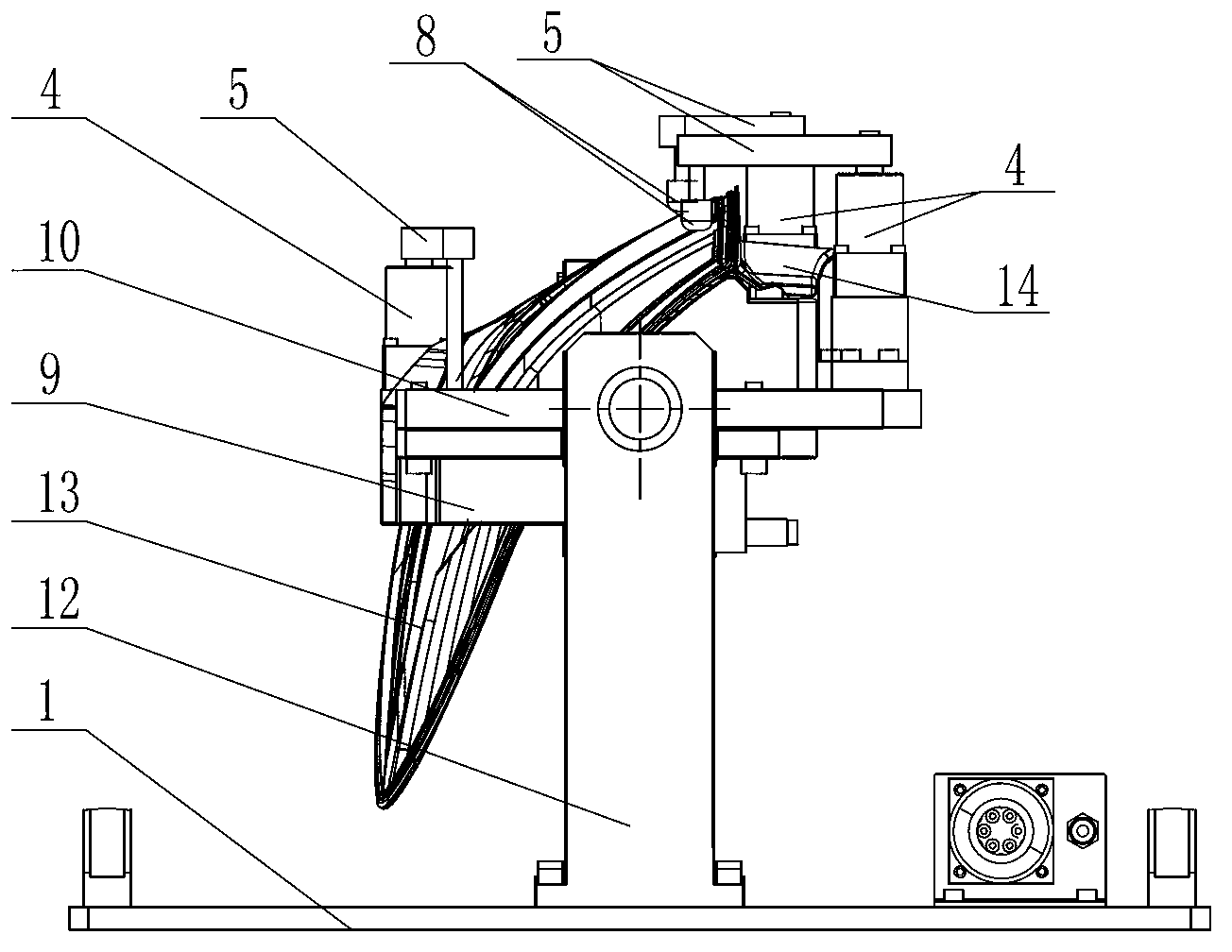

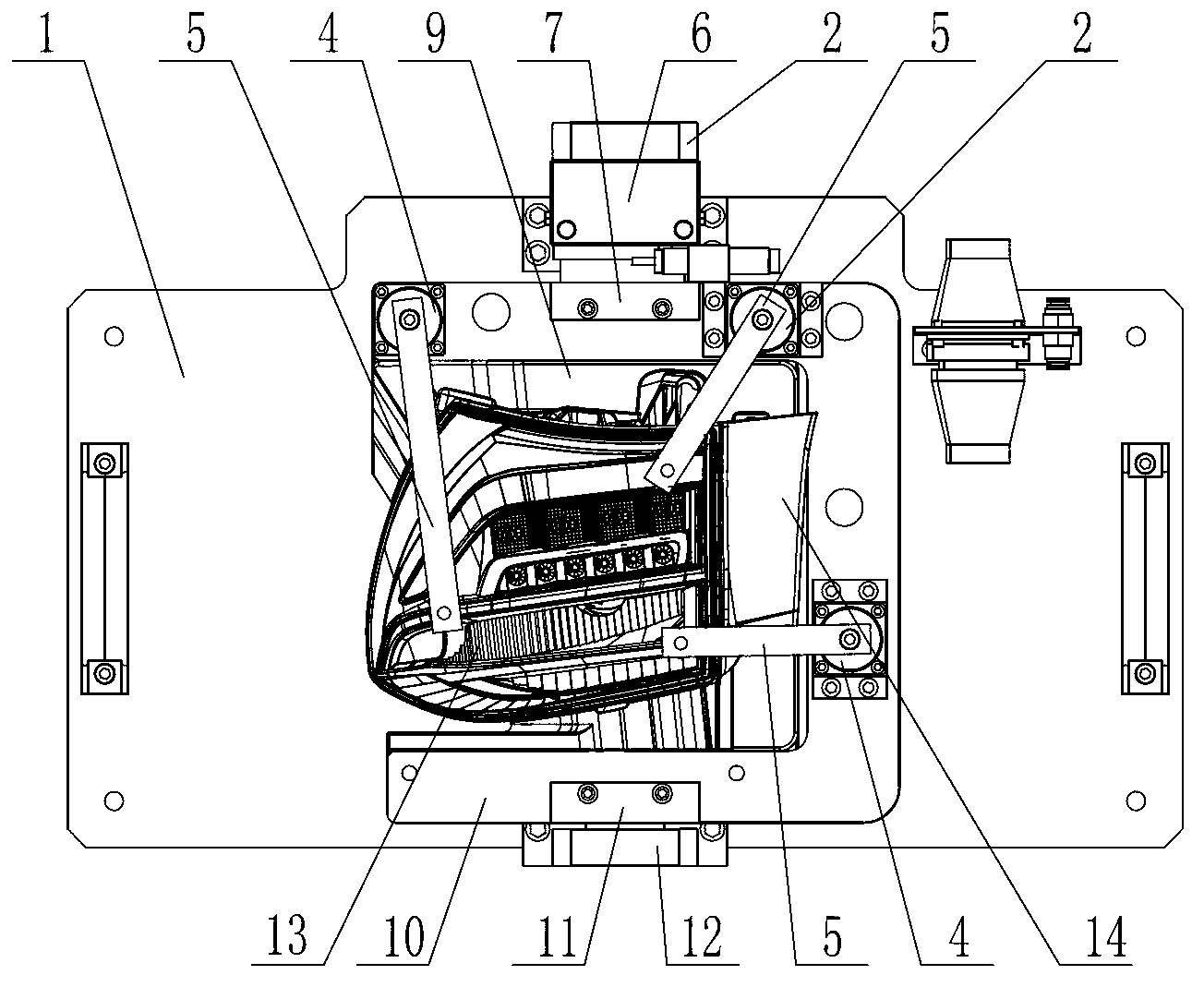

[0014] See Figure 1~6 As shown, the assembly device of the automotive lamp bezel and the housing of the present invention includes a bottom plate 1, a rotating support mechanism, a housing positioning template 9 and a pressing mechanism.

[0015] See Figure 1~6 As shown, the rotary support mechanism of the present invention includes a first support 2, a second support 12, a corner cylinder 6, a driving shaft seat 7, a driven shaft seat 11 and a support seat 10, and the first support 2 and the second support 12 are respectively installed on the bottom plate 1, the corner cylinder 6 is installed on the first support 2, the rotating shaft 6-1 of the corner cylinder 6 is fixedly connected with the driving shaft seat 7, and can be connected by fasteners, and the driving shaft is driven by the corner cylinder 6 Seat 7 rotates together, and corner cylinder 6 of the present invention can lock automatically after reaching the specified rotation angle. See figure 1 As shown, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com