Assembly structure for tire pressure transmitter and inflating valve

A technology of tire pressure and assembly structure, applied in tire inflation valve, tire measurement, tire parts and other directions, can solve the problems of large change angle of antenna, large change angle of tire pressure transmitter, and degradation of signal transmission quality, and achieves the rotation point. Small force, small change angle, the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

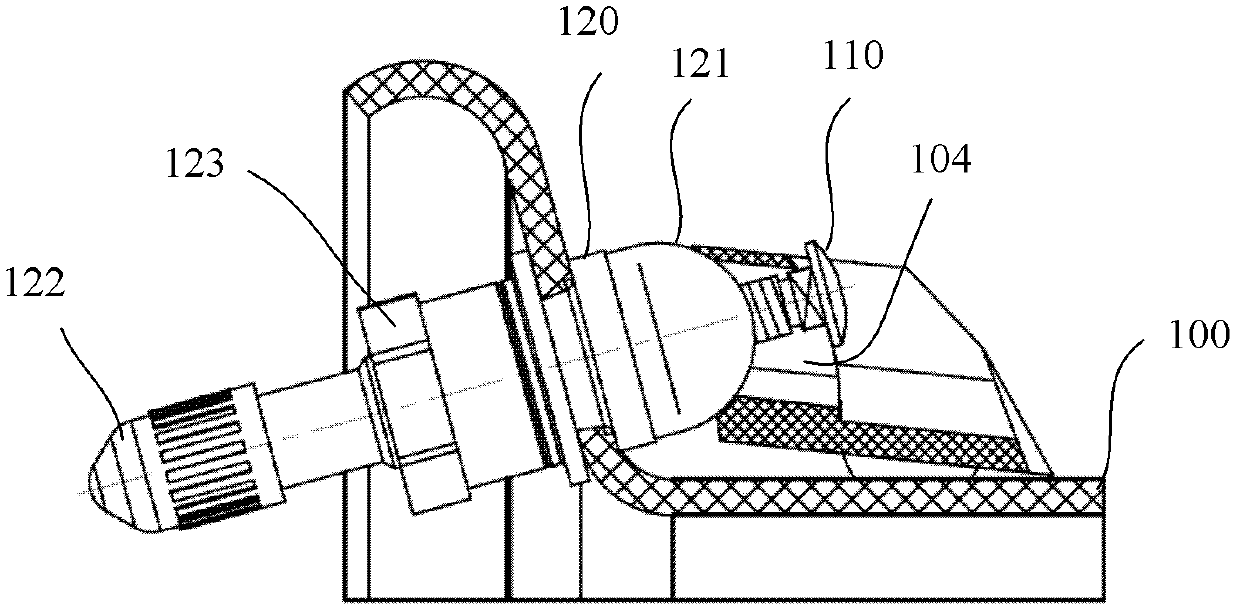

[0025] image 3 It is an exploded view of the assembly structure of the tire pressure transmitter and the valve according to the first embodiment of the present invention. Such as image 3 As shown, the assembly structure 200 includes a valve connector 201 , a small shaft 202 , a set screw 203 and a tire pressure transmitter connector 204 . The valve connecting head 201 is used for connecting the assembly structure 200 and the valve 210 . Here, the valve 210 is an ordinary valve. The tire pressure transmitter connector 204 is used to be combined with the casing 220 of the tire pressure transmitter so as to be connected with the assembly structure 200 .

[0026] In this embodiment, the valve connector 201 , the small shaft 202 , the set screw 203 and the tire pressure transmitter connector 204 are all independent components. The air valve connecting head 201 and the air valve 210 can be threaded.

[0027] combined reference Figure 7 As shown, the end face of the valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com