Disconnect-type oil jack

A jack and separate technology, applied in the direction of lifting device, etc., can solve the problems of low work efficiency, troublesome sealing, poor sealing, etc., and achieve the effects of convenient operation, stable work and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

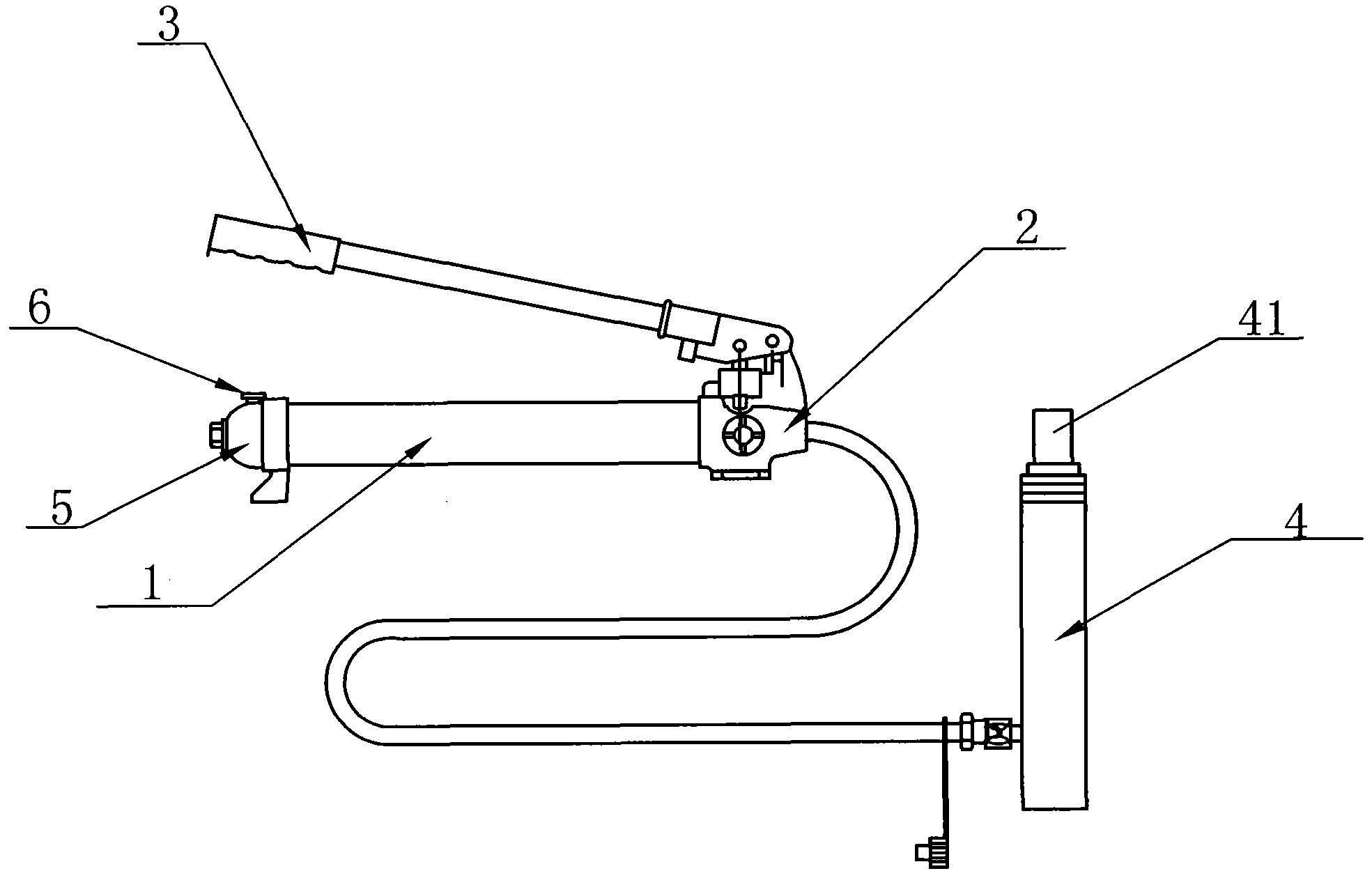

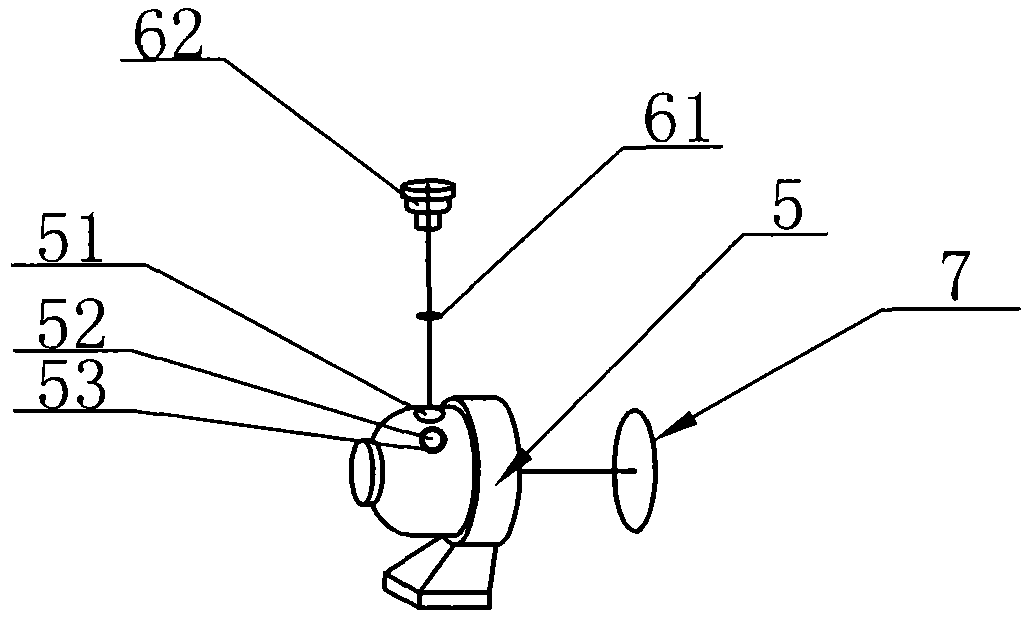

[0012] see figure 1 and figure 2 , a separate hydraulic jack disclosed by the present invention, comprising an oil storage tank 1, a pump body 2 installed at the front end of the oil storage tank 1, the pump body 2 is provided with an operating handle 3, and the pump body 2 is connected to There is an oil cylinder 4, and the piston rod 41 of the oil cylinder is controlled to rise and fall through the operating handle 3. The rear end of the oil storage cylinder 1 is provided with a rear seat 5, and the top of the rear seat 5 is fixedly provided with a refueling valve 6, and the top of the rear seat 5 is provided with Refueling port 51, the refueling valve 6 includes a first O-ring seal 61 and a bolt 62, the refueling valve 6 clamps the first O-ring seal 61 by tightening the bolt 62 to seal the refueling port 51, the upper end of the rear seat 5 is set There is an observation port 52 for observing the oil storage amount, and a transparent safety plate 53 is arranged at the obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com