Compact oil and gas and water cooler

An oil-air-water, cooler technology, applied in engine cooling, machine/engine, engine lubrication, etc., can solve the problem of large space occupation, reduce installation space, reduce weight, and improve cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

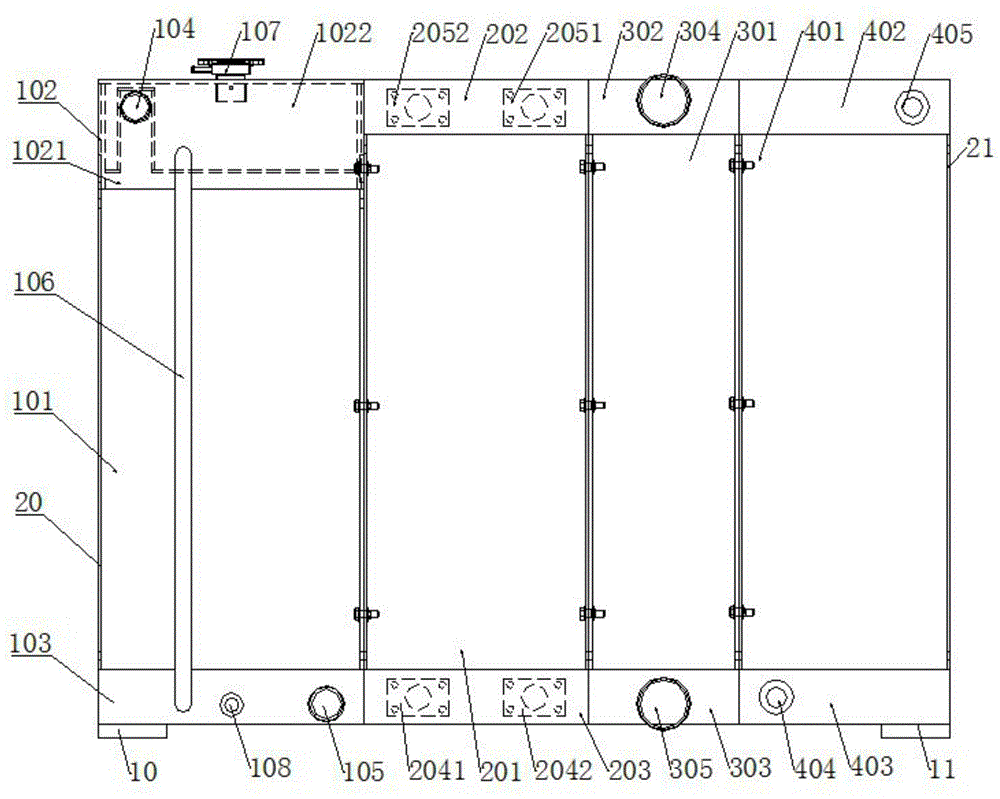

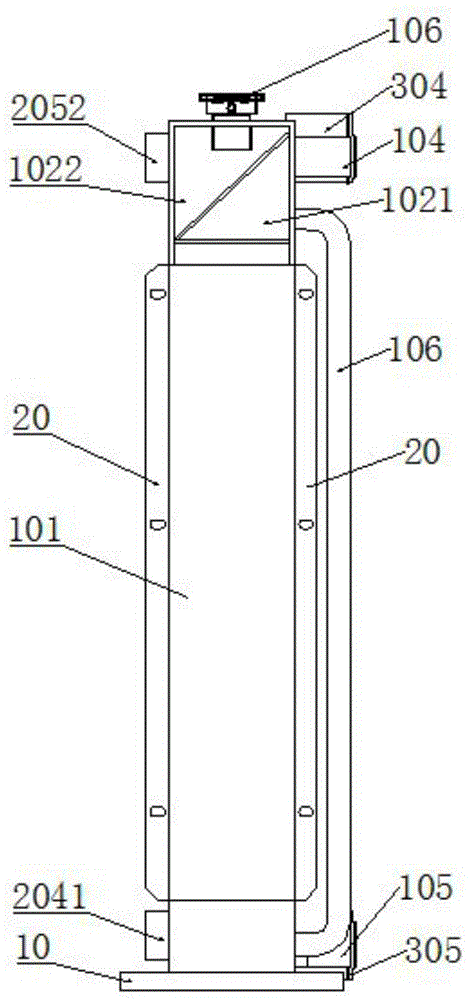

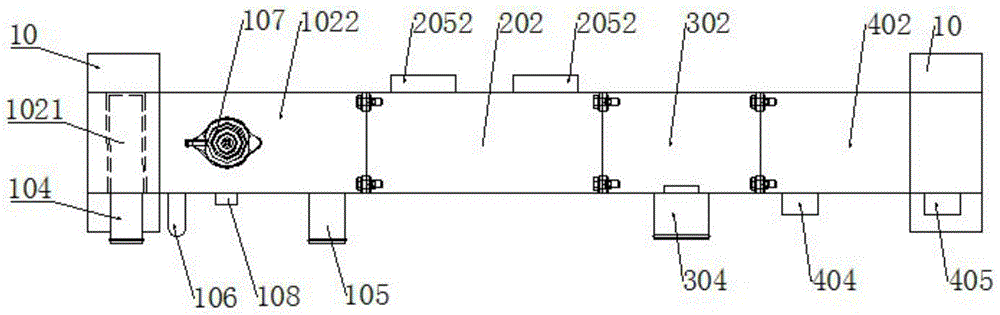

[0030] figure 1 It is the front view of the compact oil-air-water cooler provided by Embodiment 1 of the present invention; figure 2 It is the left view of the compact oil-air-water cooler provided by Embodiment 1 of the present invention; image 3 It is a top view of the compact oil-air-water cooler provided by Embodiment 1 of the present invention; as shown in the figure, the compact oil-air-water cooler provided by Embodiment 1 of the present invention includes: a water cooling body 101 with a built-in water-cooling core, and a built-in first The first oil cooling body 201 with an oil cooling core, the air cooling body 301 with a built-in air cooling core, the second oil cooling body 401 with a built-in second oil cooling core, and the right plate of the water cooling body 101 are fastened and connected by bolts The left plate of the first oil cooling body 201 and the right plate of the first oil cooling body 201 are fastened to the left plate of the air cooling body 301 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com