Fiber rod cutting device of carding machine coiler

A technology of cutting device and sliver coiler, which is applied in fiber processing, deburring device, textile and paper making, etc. It can solve the problems of reduced sliver speed and impact on production efficiency, and achieves reasonable position setting, simple structure and good reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

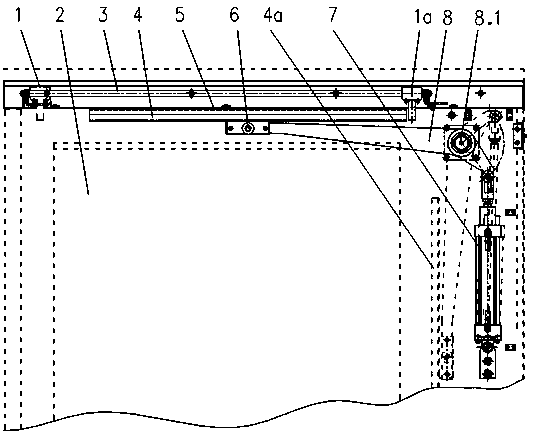

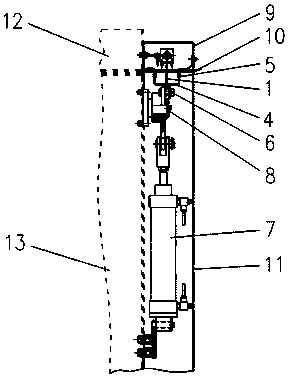

[0021] see figure 1 , figure 2 , an embodiment of a fiber strip cutting device of a carding machine coiler of the present invention, comprising a fiber strip cutting device, a coiler large column 13, a coil top box 12, a can 2 comprising a working cylinder and a full cylinder, The sliver cutting device is set between the working cylinder and the full cylinder close to the coiler, figure 2 The sliver cutting device is shown on the left in the mandrel position and on the right in the full drum position. The fiber strip cutting device includes a cutter 1, a strip cutting cylinder 3, a u-shaped support plate 4, a u-shaped support plate swing center shaft 6, a swing arm cylinder 7, a swing arm 8, a swing arm rotation center shaft 8.1 and a strip cutting support base plate 10. The swing arm cylinder 7 is vertically fixed on one side of the large column 13 of the coiler....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com