Superposition-screw type sludge deep dehydrator

A deep dehydration and screw stacking technology, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of complex structure, high price, easy damage of filter cloth, etc., achieve good working conditions and environmental interface, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

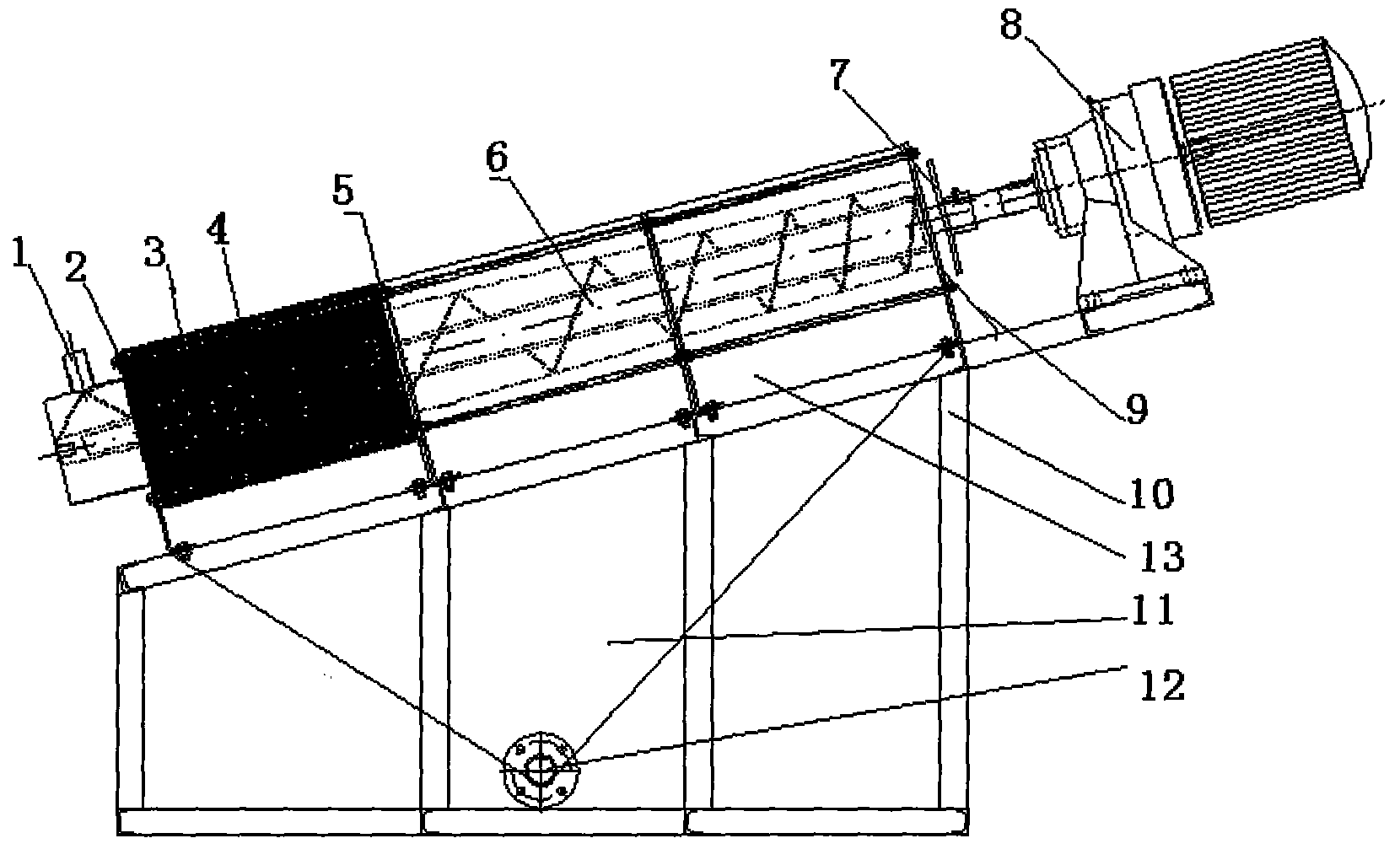

[0019] A stacked screw type sludge deep dewatering machine, such as figure 1 As shown, the variable-diameter movable and fixed ring 3 is fixed on the equipment casing 13 through the fixing bolt 4 and the fixing plate 5. One end of the screw shaft 6 is provided with a groove, which fits with the built-in cylindrical boss at one end of the equipment casing 13. The screw shaft 6 After being connected with the deceleration motor 8 at the other end, it is fixed on the equipment support 10 together. The feeding port 1 is set at the front end of the screw shaft 6, and the discharge port 9 is set at the rear end of the screw shaft 6. The fixed ring 3 is connected, the back pressure plate 7 is arranged on the rear end of the screw shaft 6 , and the liquid collection tank 11 and the liquid discharge port 12 are arranged on the equipment support 10 . The screw shaft 6 is a variable diameter screw shaft.

[0020] The working principle of the above-mentioned sludge deep dewatering machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com