Loaded type metallocene catalyst for vinyl polymerization and preparation method thereof

A metallocene catalyst and ethylene polymerization technology, applied in the production of bulk chemicals, etc., can solve the problems of unsatisfactory regulation of catalyst particle shape and particle size distribution, poor polymer particle shape, and inability to meet the needs of industrialization, etc., to achieve easy polymerization process Controlled, controllable shape, beneficial to large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

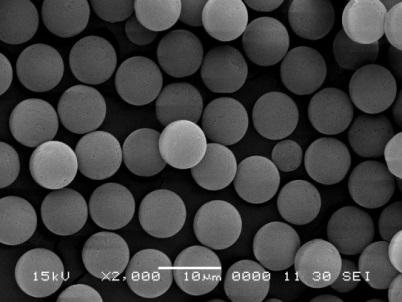

[0045] A preparation method for a supported metallocene catalyst for ethylene polymerization, specifically comprising the steps of:

[0046] ①Supercritical carbon dioxide assisted loading: add an aromatic hydrocarbon solution of metallocene compound to the polymer carrier, place it in a high-pressure reactor, pass in carbon dioxide, raise the temperature and pressurize until the carbon dioxide reaches a supercritical state, and use supercritical carbon dioxide to swell the polymer carrier;

[0047] ②Catalyst activation: After the swelling is completed, the pressure is slowly released, and nitrogen replacement is introduced for 5 to 10 times, and then a certain proportion of co-catalyst is added to the swelled catalyst intermediate to activate the catalyst;

[0048] ③Drying and forming: Add hexane solution into the reactor, wash it repeatedly for 5-10 times, remove the solvent in steps ① and ②, and dry to obtain a highly active supported metallocene catalyst.

Embodiment 1

[0051]The preparation steps of supported metallocene catalyst for ethylene polymerization are:

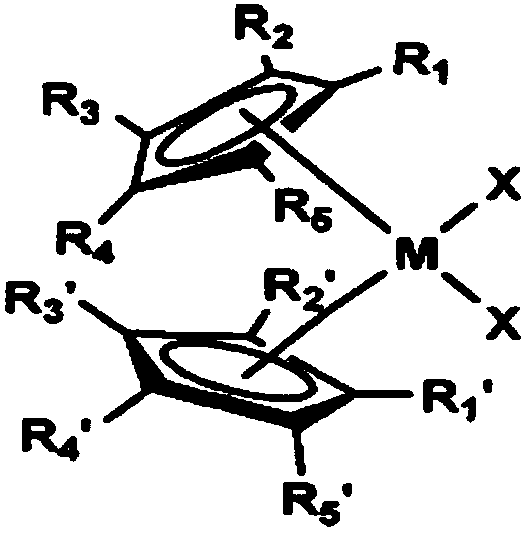

[0052] ①Supercritical carbon dioxide assisted loading: add 0.1mol / l (abbreviated as 0.1M, the same below) dichloro 4ml of zirconocene toluene solution is placed in a high-pressure reactor, and carbon dioxide is introduced, and the swelling penetration temperature is raised to 40°C, and the swelling pressure is increased to 10.0MPa, so that the carbon dioxide reaches a supercritical state, and the supercritical carbon dioxide is used to swell the polymer carrier 4 Hour;

[0053] ②Catalyst activation: Slowly release the pressure after the swelling is completed, cool down to room temperature, pass nitrogen into the reactor for 5 to 10 times, then add 200ml of 1M methylaluminoxane toluene solution, heat up to 60°C and reflux for 1 to 4 Hours for catalyst activation;

[0054] ③ Drying and forming: Add 500ml of hexane solution into the reactor, wash it repeatedly for 5-10 times, remove...

Embodiment 2

[0059] Except that zirconocene dichloride was replaced by bis(ethylcyclopentadiene) zirconium dichloride, the preparation method of the catalyst component was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com