Quick opening hydrant

A fire hydrant and fast technology, which is applied in the field of quick opening fire hydrants, can solve the problems of self-closing anti-collision fire hydrants, such as rapid opening, bending deformation of the valve stem, and poor sealing of the valve plate, so as to ensure reliability and prevent The effect of freezing the device and opening it quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

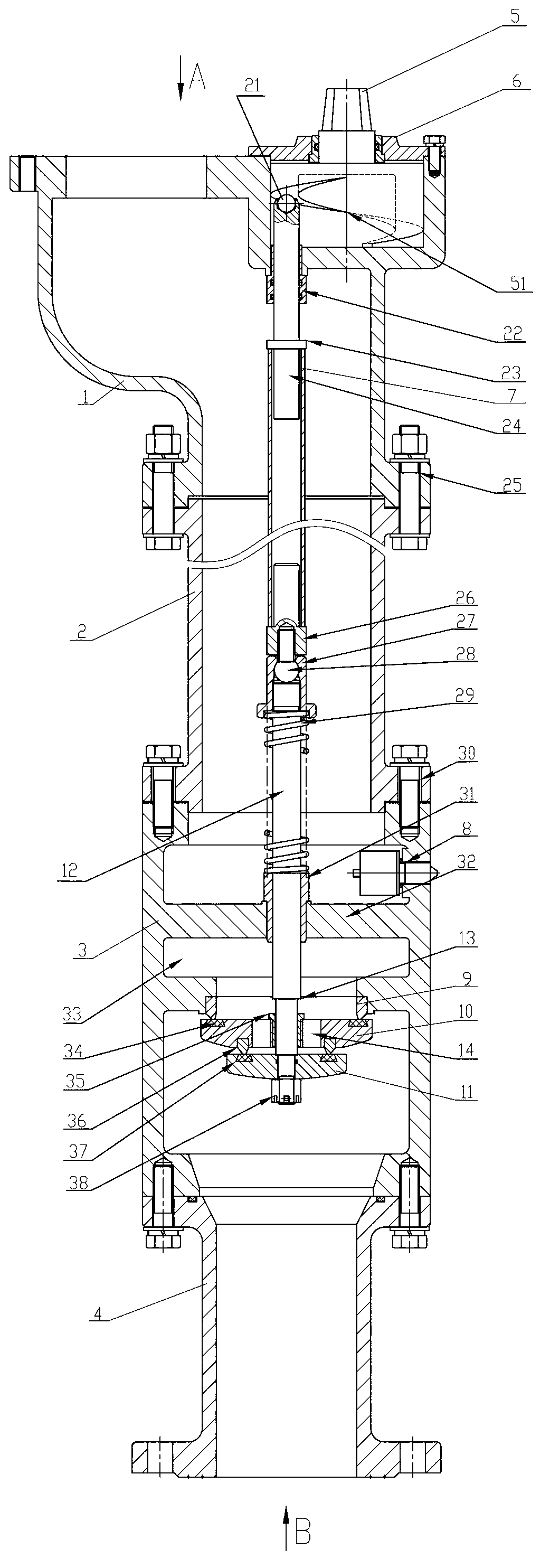

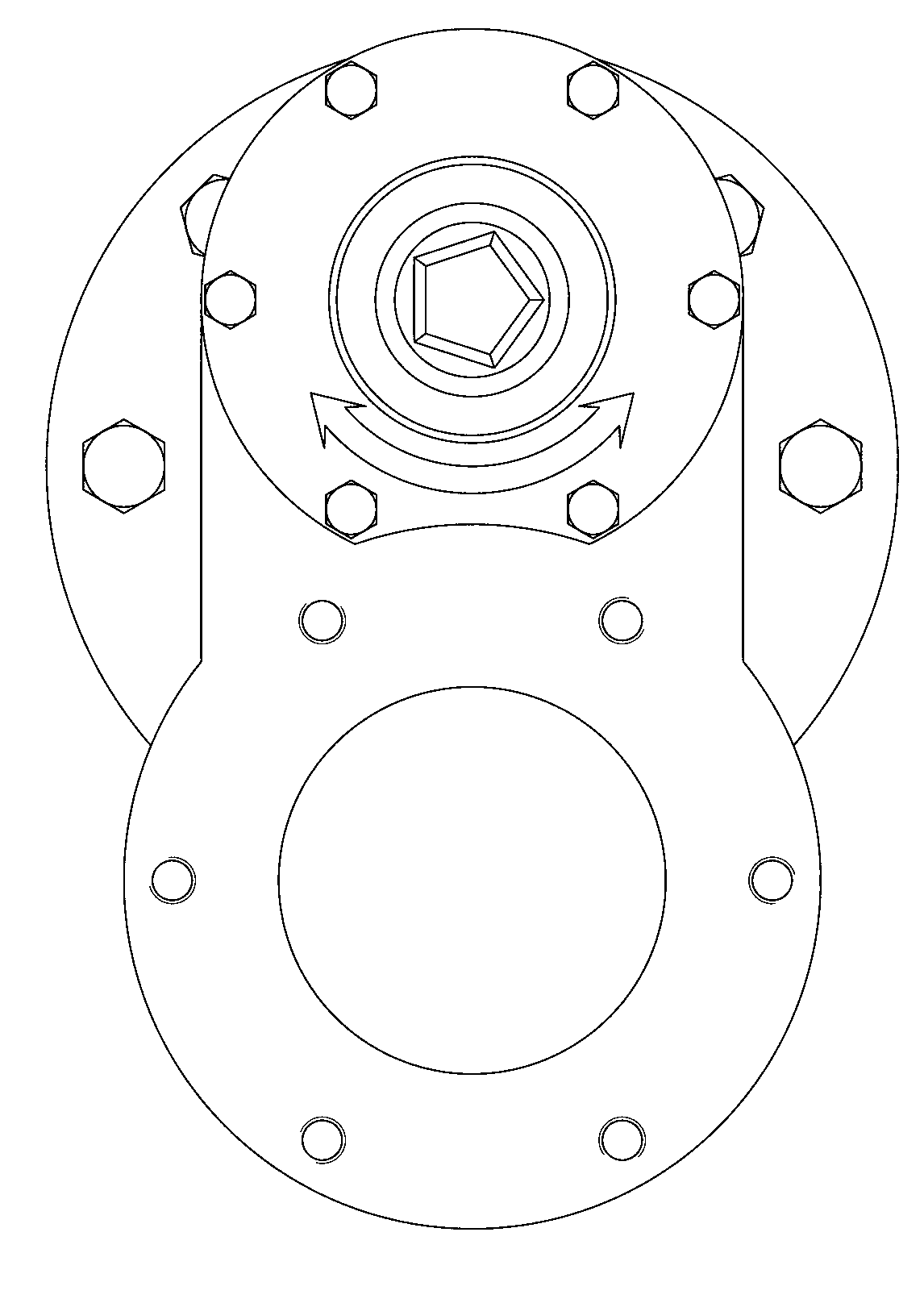

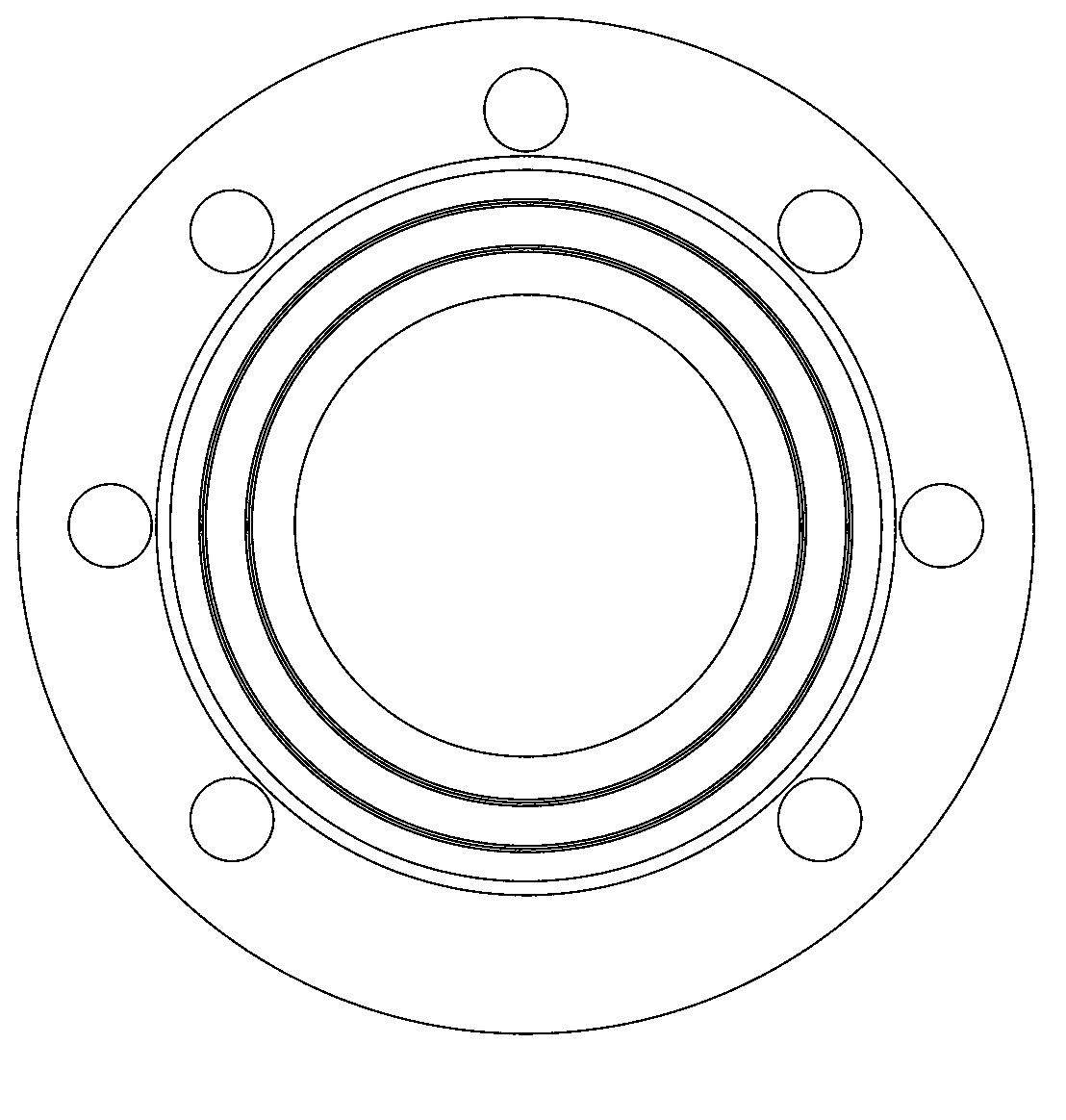

[0019] Describe in detail below in conjunction with accompanying drawing, as figure 1 , figure 2 , image 3 shown.

[0020] A quick-opening fire hydrant has an overall structure including a body 1 , a base 2 , a valve body 3 and a base 4 . The body 1 and the base body 2 are connected by connecting bolts 25 , and a sealing ring or gasket is provided between the body 1 and the base body 2 . The base body 2 and the valve body 3, and the valve body 3 and the base 4 are connected by connecting screws 30, and sealing rings or gaskets are also provided at the joints. In order to combine tightly and reliably, the joint surfaces between the body 1 and the base body 2 and between the base body 2 and the valve body 3 adopt non-uniform tongue-and-groove structures.

[0021] The valve body 3 is provided with a valve plate sealingly matched with the end surface of the medium flow port, and the axially movable valve stem connected with the valve plate protrudes from the body and is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com