Double-layer light-steel-keel sound-insulating wall and construction method thereof

A light steel keel and construction method technology, applied in walls, building components, buildings, etc., can solve the problems that light steel keel cannot meet the structural stability, the technical level of construction personnel is high, and the structure of light steel keel is complex. Achieve the effects of good sound insulation effect, easy promotion, and simple construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

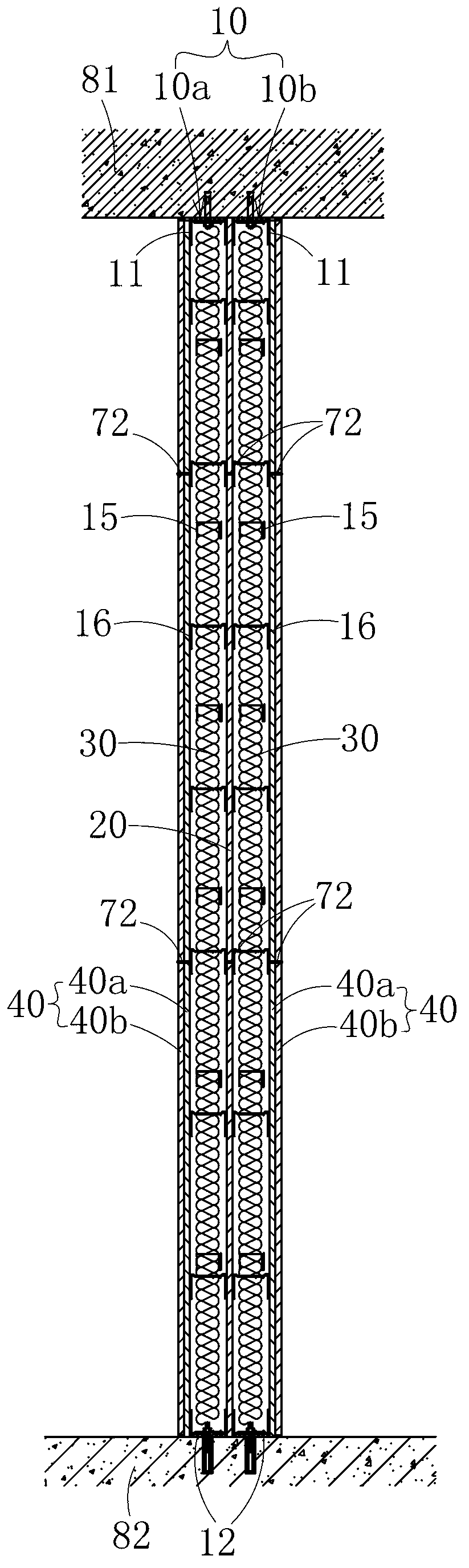

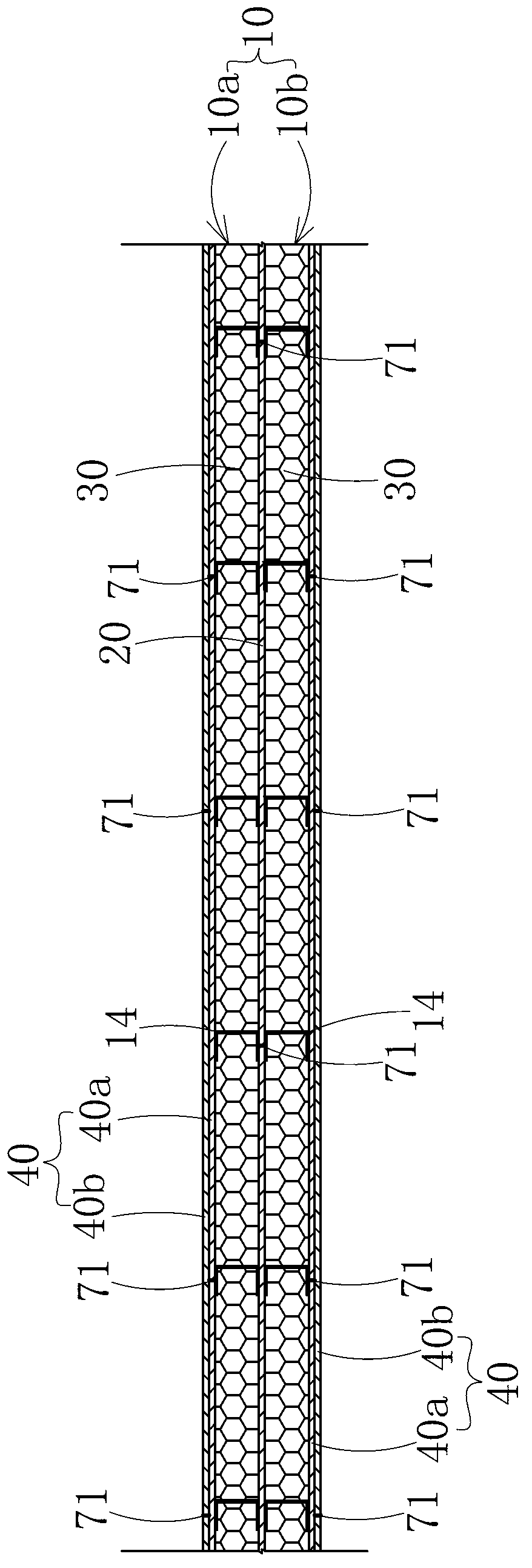

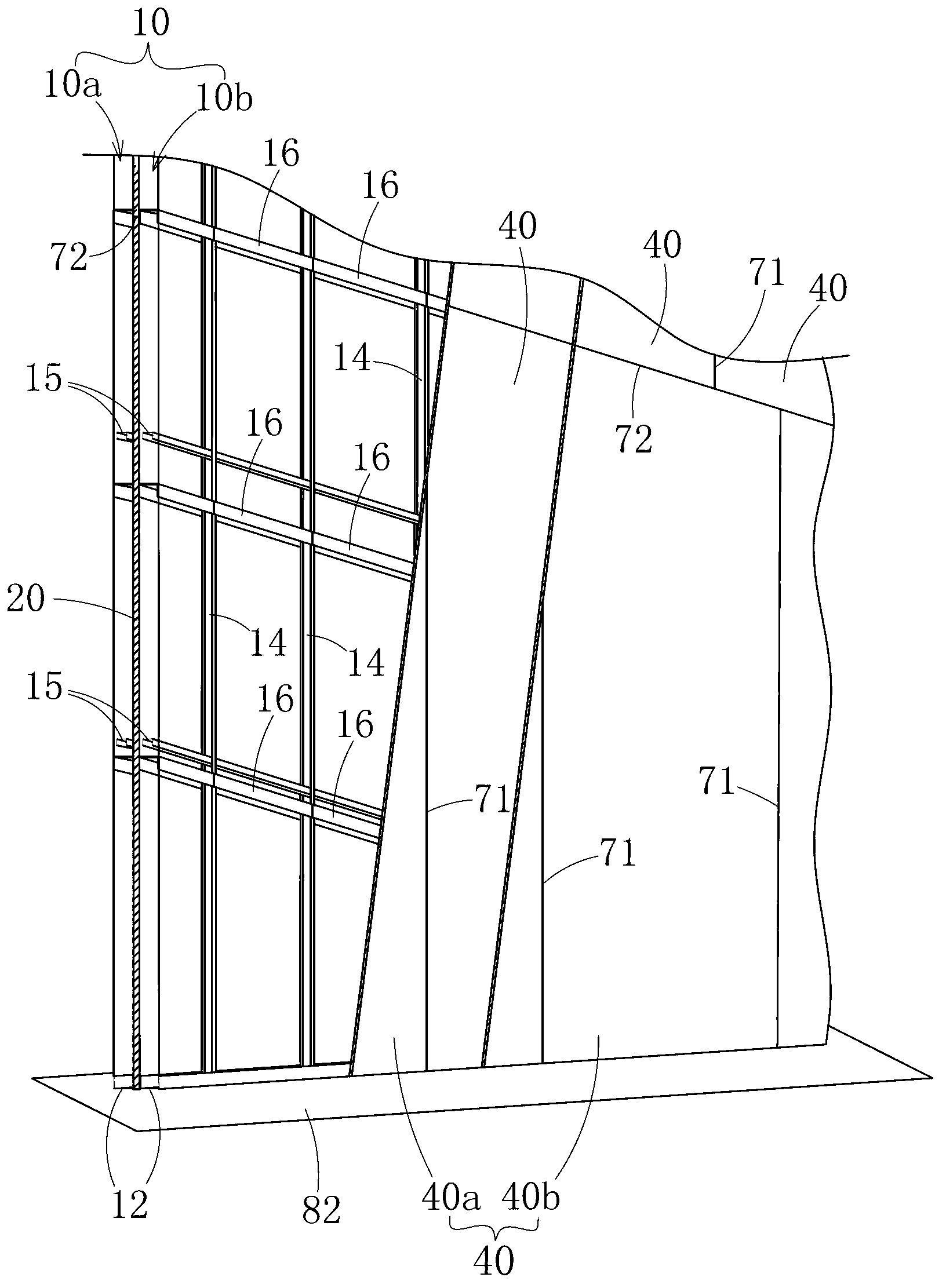

[0043] Such as figure 1 , figure 2 with image 3 The vertical sectional structure diagram (height of 6m), the partial cross-sectional structure diagram and the bottom three-dimensional partial sectional view of a double-layer light steel keel sound insulation wall of the present invention are shown to clearly show the light steel keel structure. image 3 The filling material in is not shown. The double-layer light steel keel sound insulation wall of the present invention includes two parallel C-shaped light steel keel frames 10 with a width of 50mm, 75mm or 100mm. The structure of the light steel keel frame 10 is as figure 1 with Figure 4 As shown, the light steel keel frame 10 includes a top keel 11 fixed to an upper base 81, a ground keel 12 fixed to a lower base 82, and a frame keel (not shown in the figure) fixed to both sides of the base. The top keel 11, the ground keel 12, and the frame keel constitute an installation frame of the light steel dragon 10 to facilitate th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com