Anti-theft structure and production process of angle-steel tower material

A preparation process and steel tower technology, which is applied in the field of anti-theft structure and preparation technology of angle steel tower materials, can solve the problems of not being able to effectively prevent theft of angle steel tower materials and cables, difficulty on duty, and increasing the difficulty of cutting tower materials by thieves , to achieve the effects of reducing the theft rate, low production cost, and reducing the number of times of damage by external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

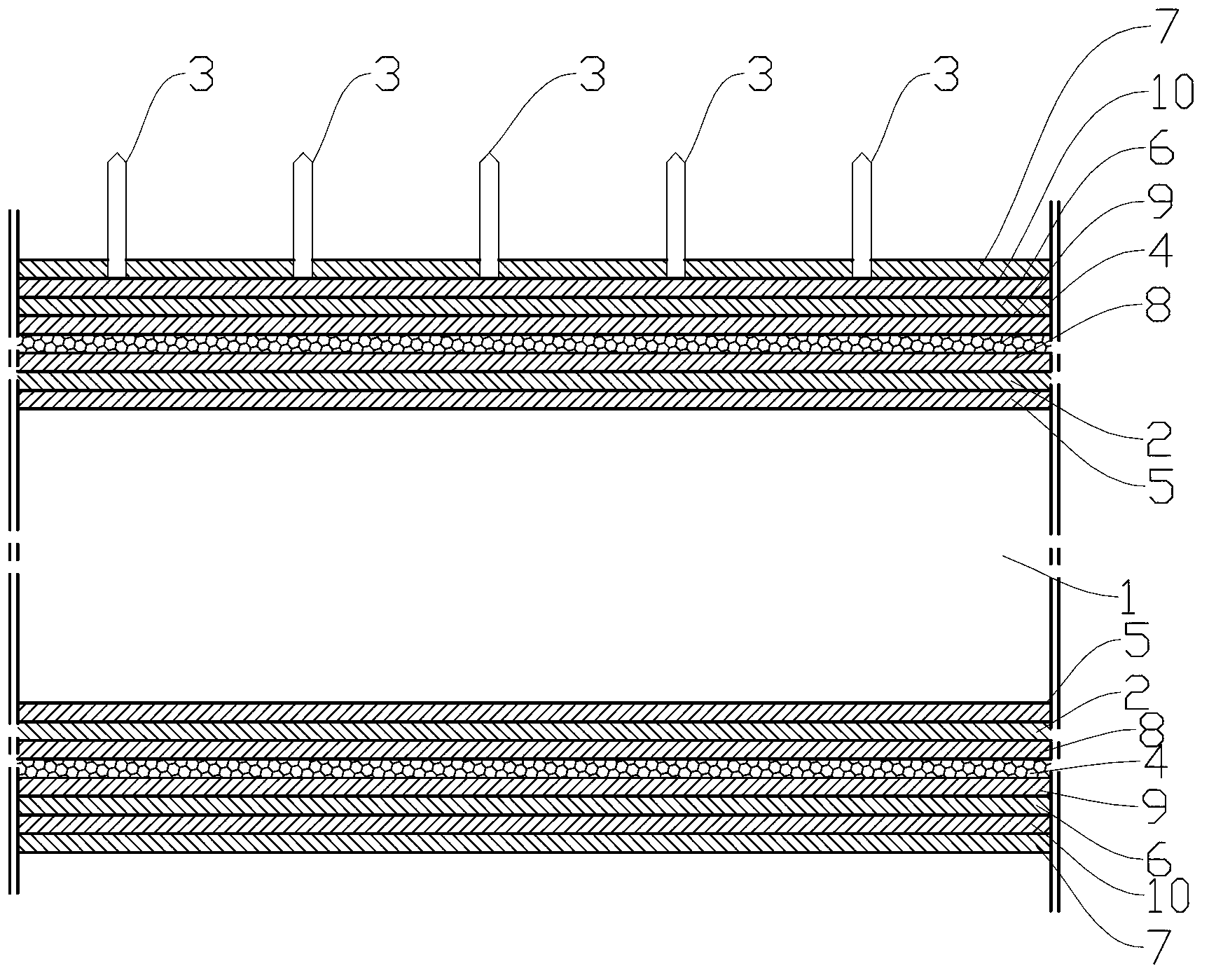

[0017] Such as figure 1 As shown, the anti-theft structure of the angle steel tower tower material of the present invention uniformly covers the first resin adhesive layer 5 on the surface of the tower material 1, and is covered with the first fiber cloth layer 2 on the surface of the first resin adhesive layer 5. The surface of the first fiber cloth layer 2 is also covered with a second resin glue layer 8, the glass flake layer 4 is pasted on the second resin glue layer 8, and the third resin glue is covered on the surface of the glass flake layer 4 Layer 9, the second fiber cloth layer 6 is covered on the surface of the third resin adhesive layer 9. When the thieves steal the tower materials, tools such as a hacksaw and an electric cutting saw used by the thieves cannot cut off the glass sheet layer 4, so that the thieves cannot steal the tower materials.

[0018] A fourth resin adhesive layer 10 is coated on the surface of the second fiber cloth layer 6, a plurality of iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com