Concrete automatic impact tester and test method thereof

A test method and technology for concrete specimens, applied in the direction of applying repetitive force/pulse force to test the strength of materials, etc., can solve the problems of low efficiency, easy deformation and scrapping of steel balls, etc., to improve service life, high test efficiency, and complete reduction The effect of the number of times of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

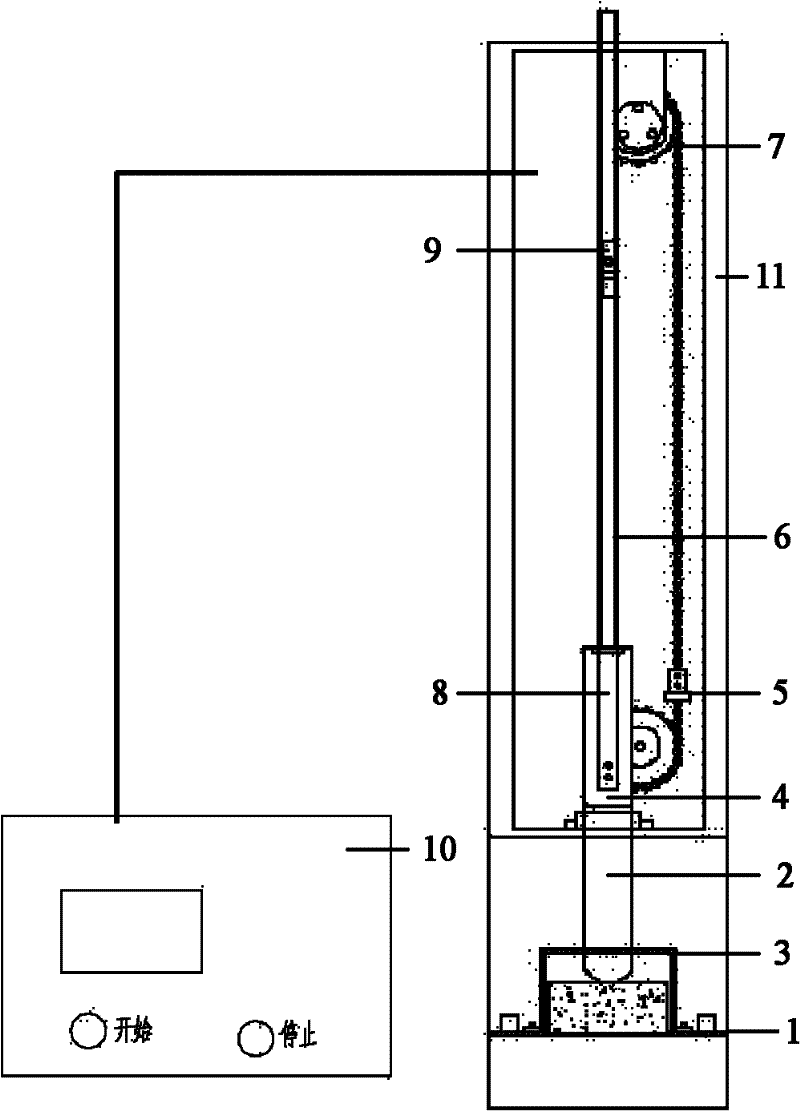

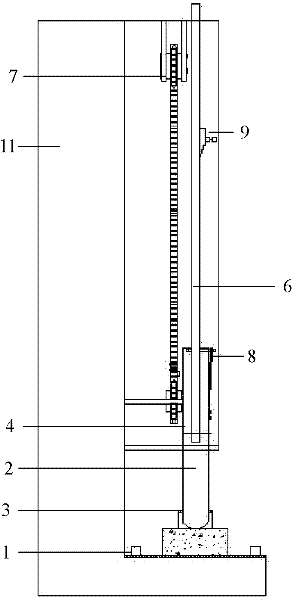

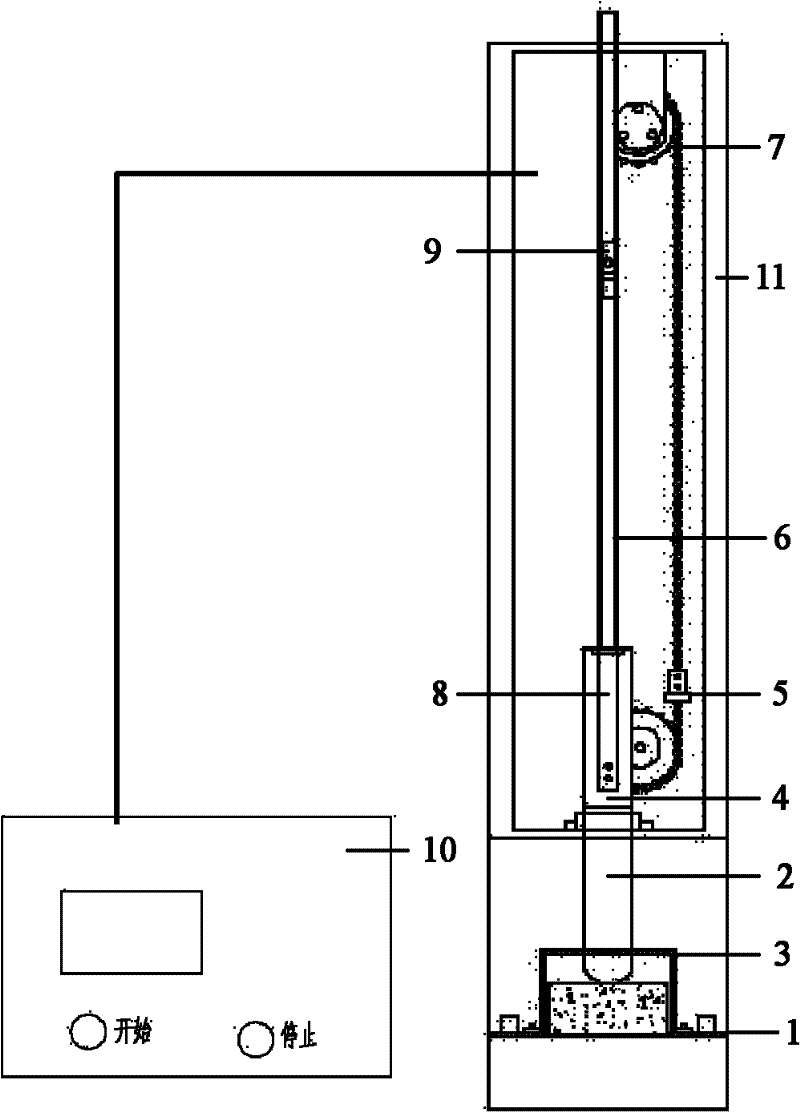

[0025] An automatic impact tester for concrete, comprising a specimen base 1, an external frame 11 is installed on the base 1, an impact hammer guide rod 6 is vertically erected inside the external frame 11, and the lower end of the impact hammer guide rod 6 Connected with an impact transmission device 2, the impact transmission device 2 is a rod-shaped device with a hemisphere at one end and a cylinder at the other end, the hemispherical end of which is in contact with the test piece; the impact hammer 4 is set on the impact hammer guide rod 6, so The impact hammer 4 is fixed on the top of the impact transmission device 2 through the impact hammer suspension mechanism 5 and contacts with its cylindrical end surface; the impact hammer 4 is equipped with an impact hammer lifting device 8, and the impact hammer lifting device 8 is fixed on the transmission device 7, the transmission device 7 is fixed in the outer frame 11 and connected with a control device 10; the impact hammer ...

Embodiment 2~5

[0039] Use PO52.5 cement, 5-10mm gravel, natural medium sand (fineness modulus 3.0), steel fiber (S f) and naphthalene series high-efficiency water reducer (FDN) to prepare fiber concrete. The concrete mix ratio is shown in Table 1. After mixing and molding and curing for 28 days, the concrete automatic impact tester prepared in Example 1 was used to test. For fiber concrete, stop once every 10 impacts to check the cracking of the concrete specimen. For concrete mixed with steel fibers, stop once every 25 impacts to check the cracking of the concrete specimen. 1. It can be seen from Table 1 that when the strength of concrete increases, its impact resistance also increases, but the number of first crack impacts is very close to the number of failure impacts, indicating that concrete without steel fibers does not have crack resistance. After the addition of steel fibers, the impact resistance of concrete is greatly improved, and the number of first-crack impacts and damage impa...

Embodiment 6

[0043] The difference between this embodiment and Embodiment 1 is that: the distance between the impact hammer ejection device 9 and the impact transfer device 2 is 1000mm; in the test method adopted, for concrete without steel fibers, step (2) The preset number of impacts in is 5; for concrete mixed with steel fibers, the steps

[0044] The preset number of impacts in (2) is 25 times.

[0045] This example takes PO42.5 cement, 5-10mm gravel, natural medium sand (fineness modulus 2.60), polypropylene fiber (PF) and naphthalene-based high-efficiency water reducer (FDN) to prepare fiber concrete as an example. The concrete mix ratio is C: W: S: G: FDN: PF = 1: 0.45: 1.95: 2.44: 0.01: 0.0075. After mixing and curing for 28 days, the concrete automatic impact tester is used to test the parameters. When setting, stop once every time there are 5 impacts, and finally measure the number of first-crack impacts as 25 times and the number of destructive impacts as 55 times. It can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com