Suction muffler for compressor

A muffler and compressor technology, applied in the field of refrigeration compressors, can solve the problems of unsatisfactory muffler effect, cumbersome production, complex structure, etc., and achieve the best noise reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

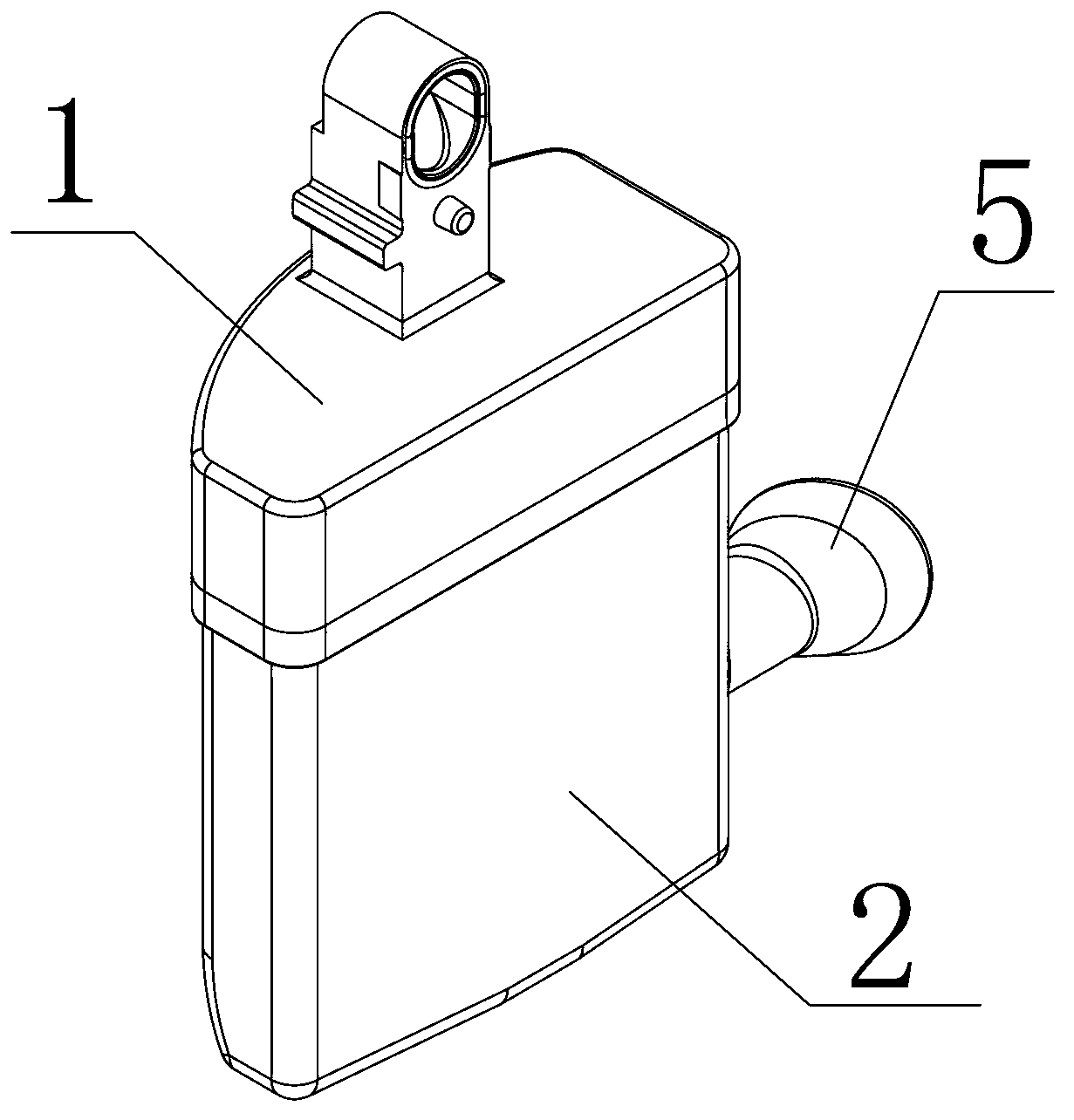

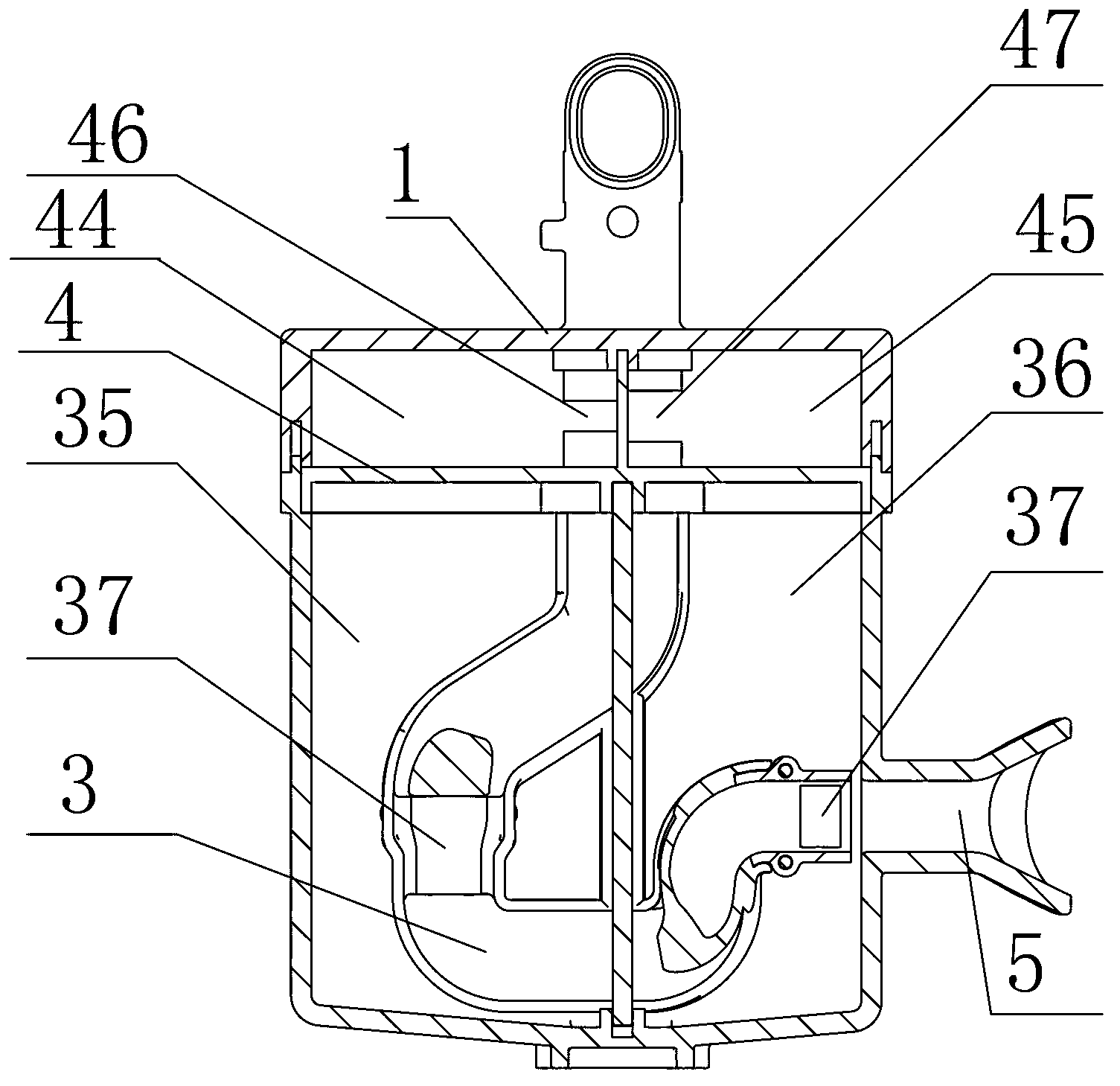

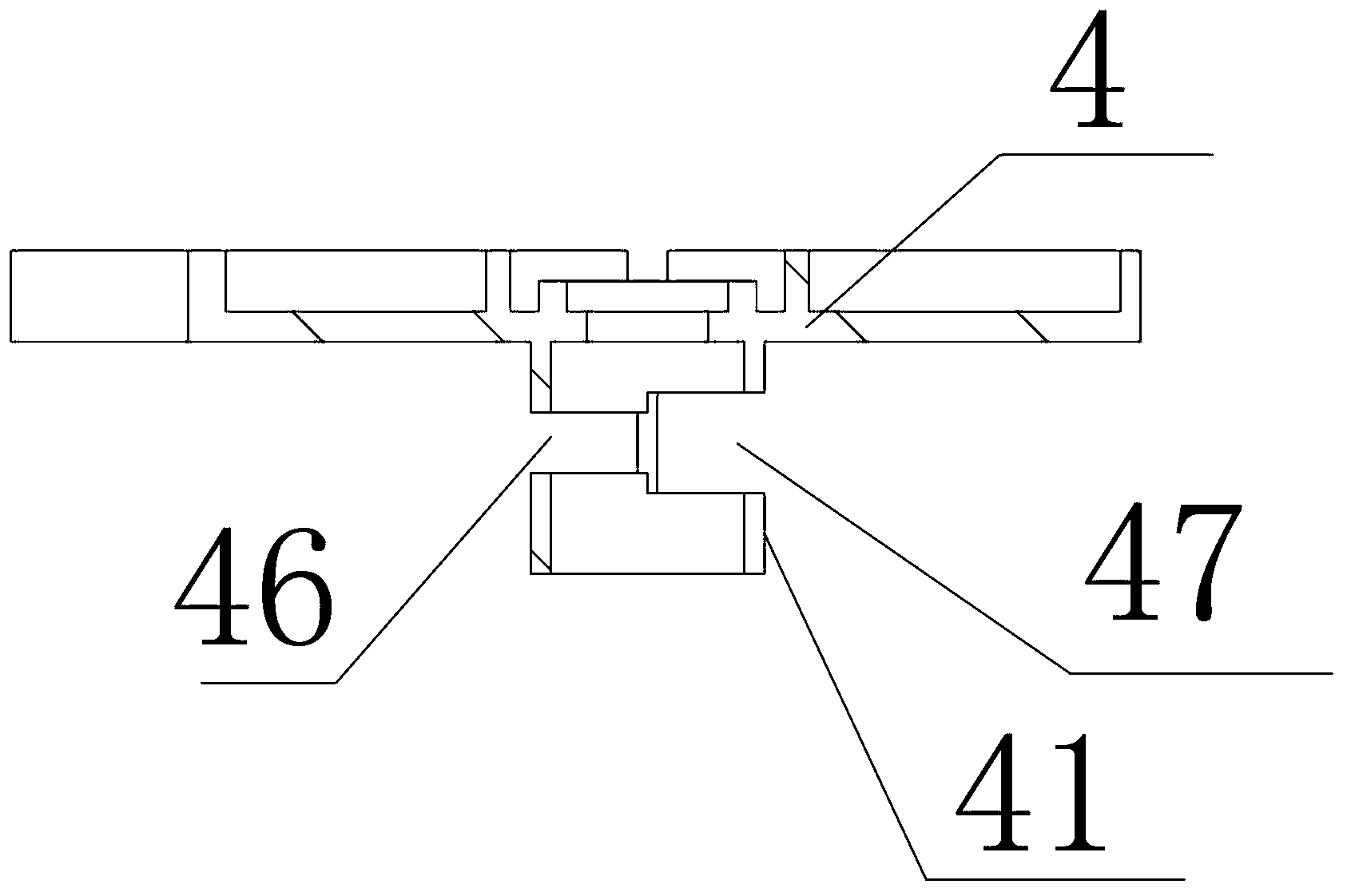

[0024] Such as Figure 1 ~ Figure 4 As shown, this embodiment includes an upper shell 1, a lower shell 2, a serpentine tube assembly 3, a partition 4 and an air suction pipe 5, the partition 4 is arranged between the upper shell 1 and the lower shell 2, and the serpentine tube The assembly 3 is arranged between the partition 4 and the lower shell 2, the suction pipe 5 is connected to the serpentine pipe assembly 3, the suction pipe 5 is located outside the lower shell 2, and the partition 4 includes a gas pipe 41, a support plate 42 and a fixed Plate 43; the support plate 42 is located on the lower shell 2, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com