Coke oven chute opening adjusting structure

A technology for adjusting the structure and the chute, which is used in coke ovens, coke oven heating, combustible gas heating coke ovens, etc. It can solve the problem that the heating system is difficult to meet the design requirements, affects the normal production of coke ovens, and cannot be accurately and quantitatively adjusted. Gas flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

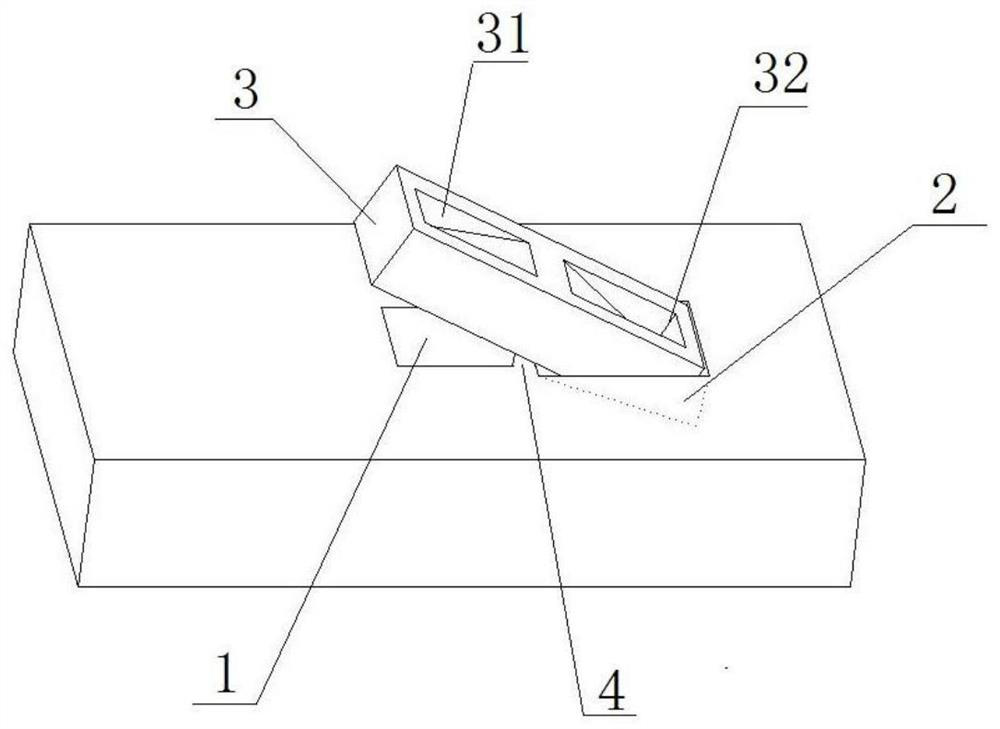

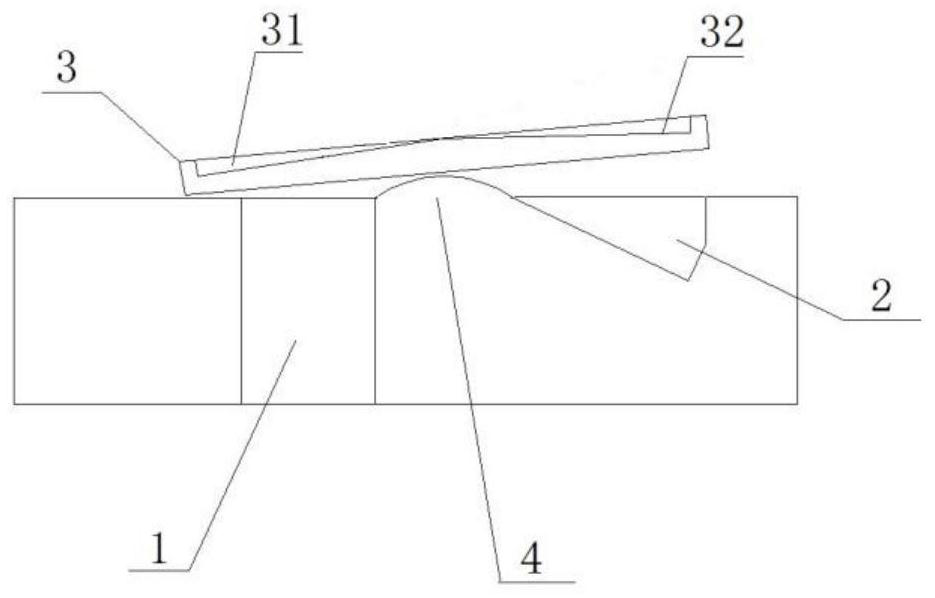

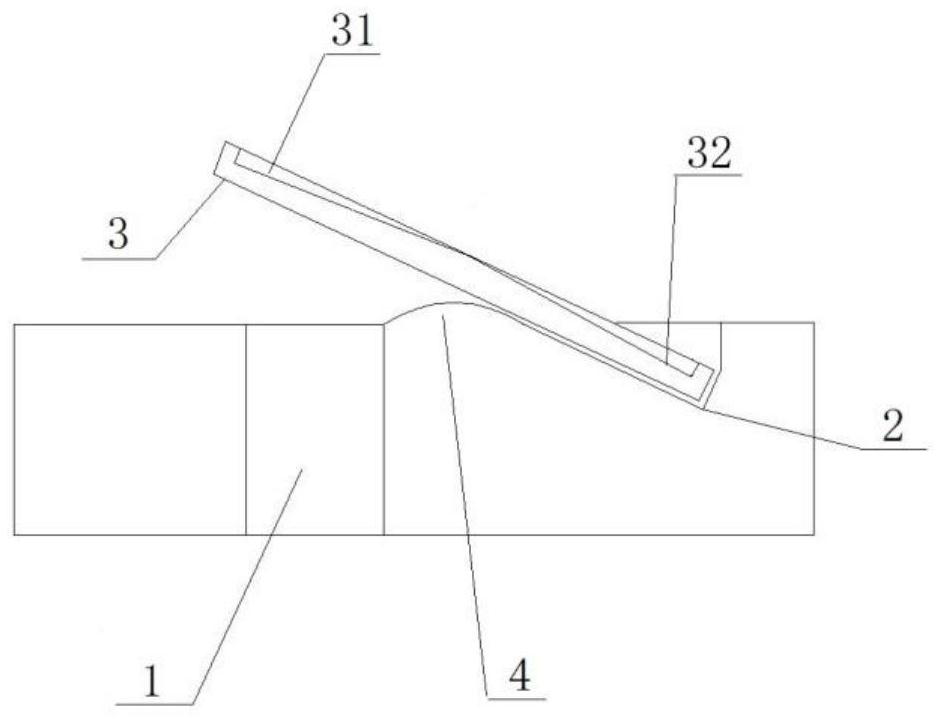

[0021] Such as figure 1 As shown, a coke oven chute opening adjustment structure according to the present invention includes an adjustment brick 3 and an adjustment brick groove 2; The chute that adjusts the brick 3 is matched, and the bottom of the groove away from the end of the chute mouth 1 is inclined to the inside and bottom of the masonry on the top of the chute mouth, and an upwardly protruding fulcrum beam 4 is provided between the adjustment brick groove 2 and the chute mouth 1; The middle part of the adjustment brick 3 is set on the fulcrum beam 4, and can rotate around the fulcrum beam 4; when the chute mouth 1 is adjusted, it is operated by the adjustment tool extending from the fire hole above the corresponding vertical fire channel, and as required, use the adjustment tool The tool presses the end of the adjustment brick 3 correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com