Modular Valve System

A modular and valve technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of restricting valve function, shortening service life, increasing wear and tear of sealing system, etc., and achieve the effect of increasing switching state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

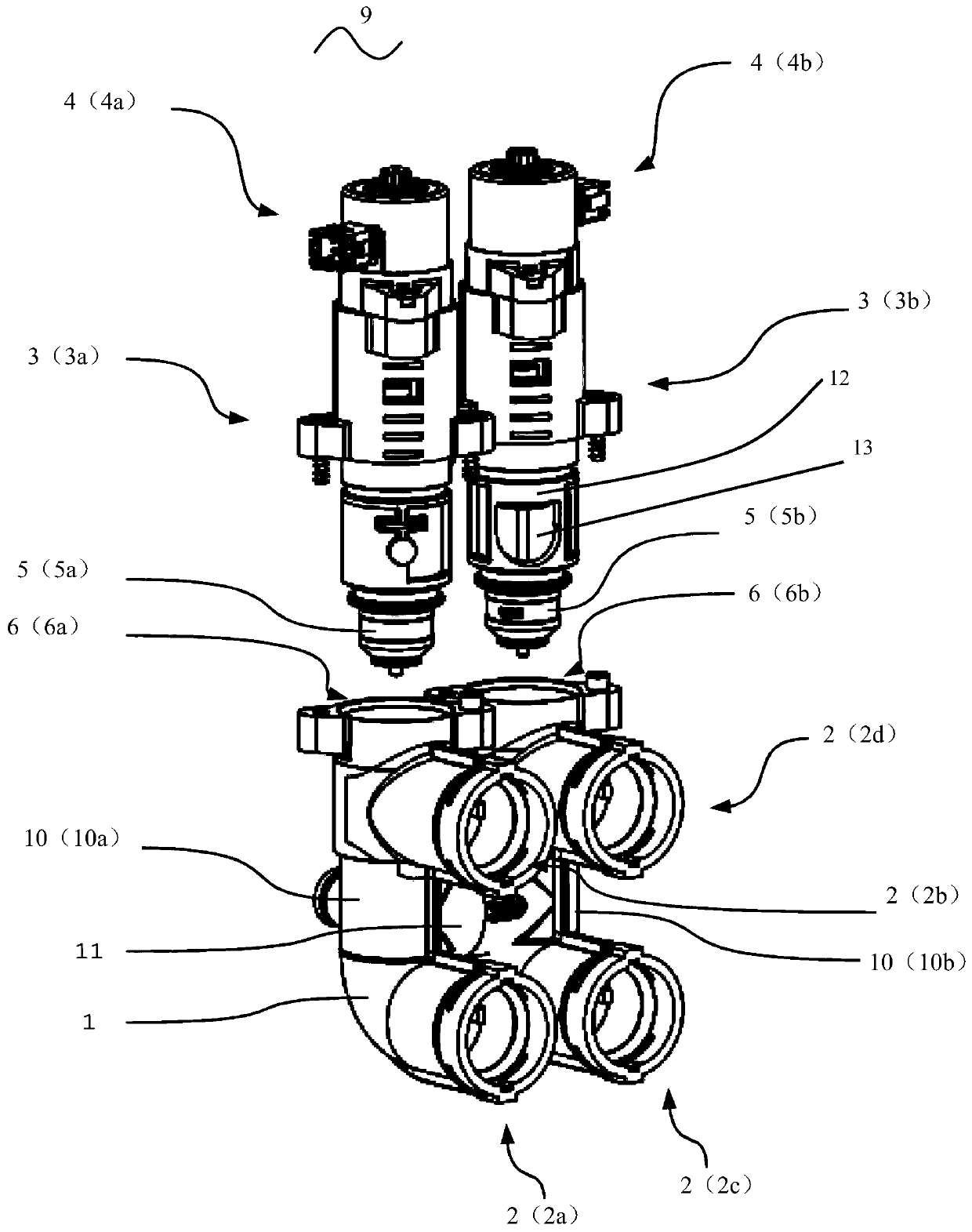

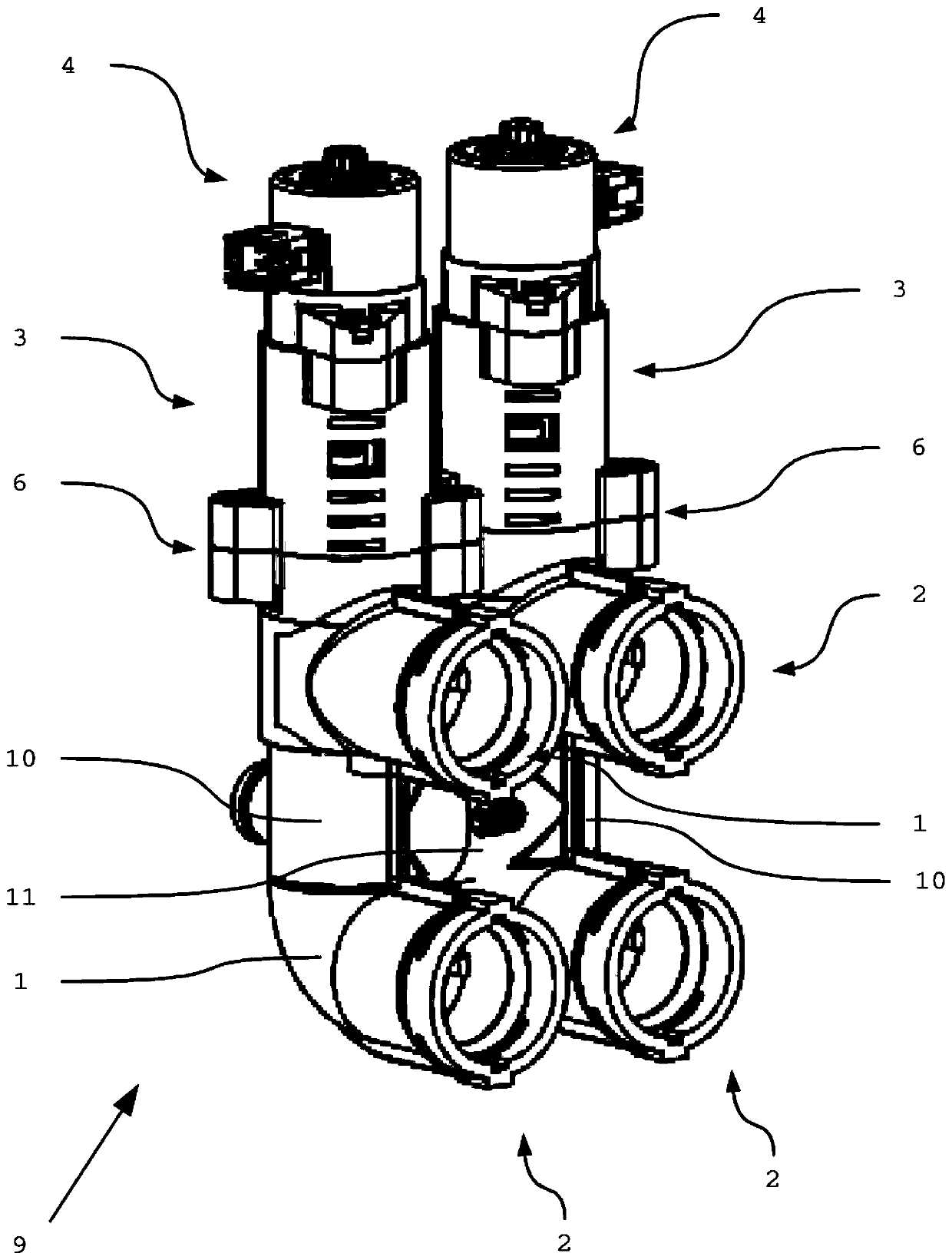

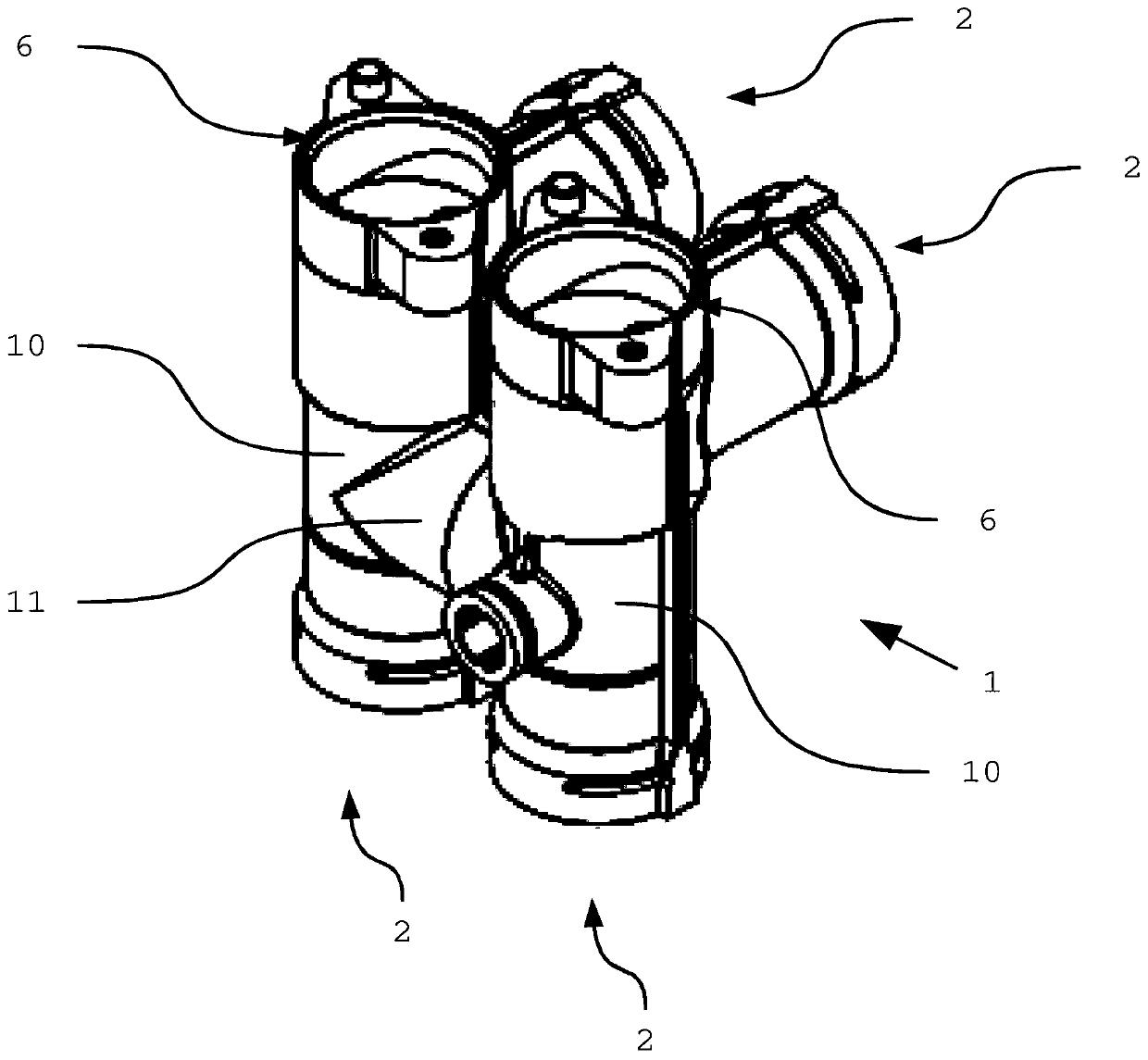

[0029] Such as figure 1 Shown is a modular valve system under this embodiment. The modular valve system is a multi-way valve 9 comprising four ports 2 . In this embodiment, the four ports 2 include a first port 2a, a second port 2b, a third port 2c and a fourth port 2d. The four ports are mainly used for switching and mixing fluids. The multi-way valve 9 includes a valve body 1 . The valve body 1 is provided with two valve cores 3, namely a first valve core 3a and a second valve core 3b. Each spool 3 has at least one linear drive 4 and one axial sealing element 5 . Specifically, the first spool 3a has a linear drive 4a and a sealing element 5a, and the second spool 3b has a linear drive 4b and a sealing element 5b. The modular valve system of the present invention is not limited to figure 1 The four-way valve system shown can also be extended to a five-way valve system, a six-way valve system or other multi-way valve systems. Based on the above structure, the valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com