Large steel tube

A steel pipe, large-scale technology, applied in the field of large-scale steel pipe protection paint device, can solve problems such as paint peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

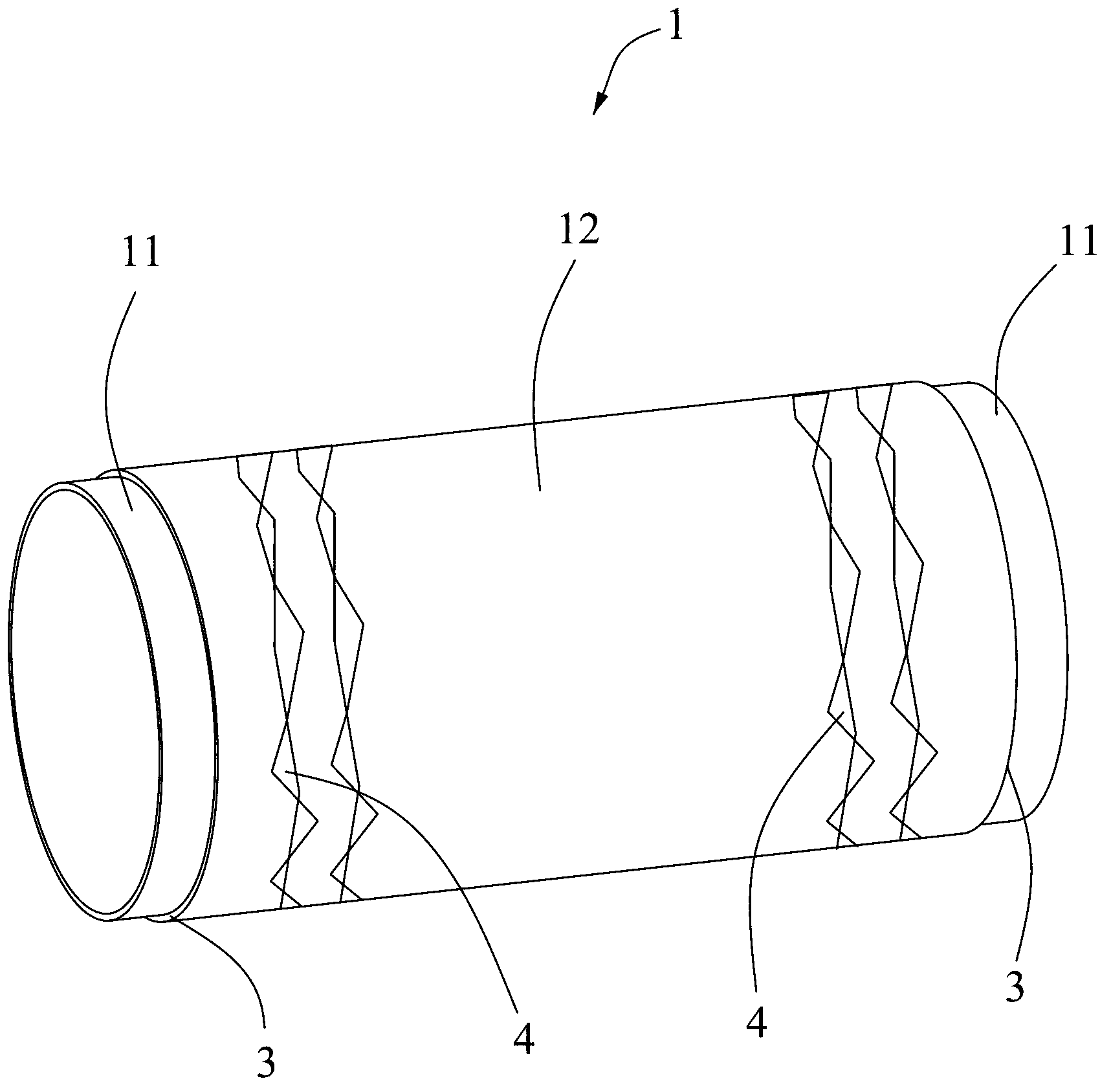

[0013] Such as figure 1 A large steel pipe 1 is shown, comprising: a cylindrical tube, paint 3 sprayed on the outside of the tube, the tube has two ends 11 and a middle part 12, and the two ends 11 have surrounding The software on its outside 4. The soft body 4 is a straw rope, and the middle 12 is not surrounded by the soft body 4 .

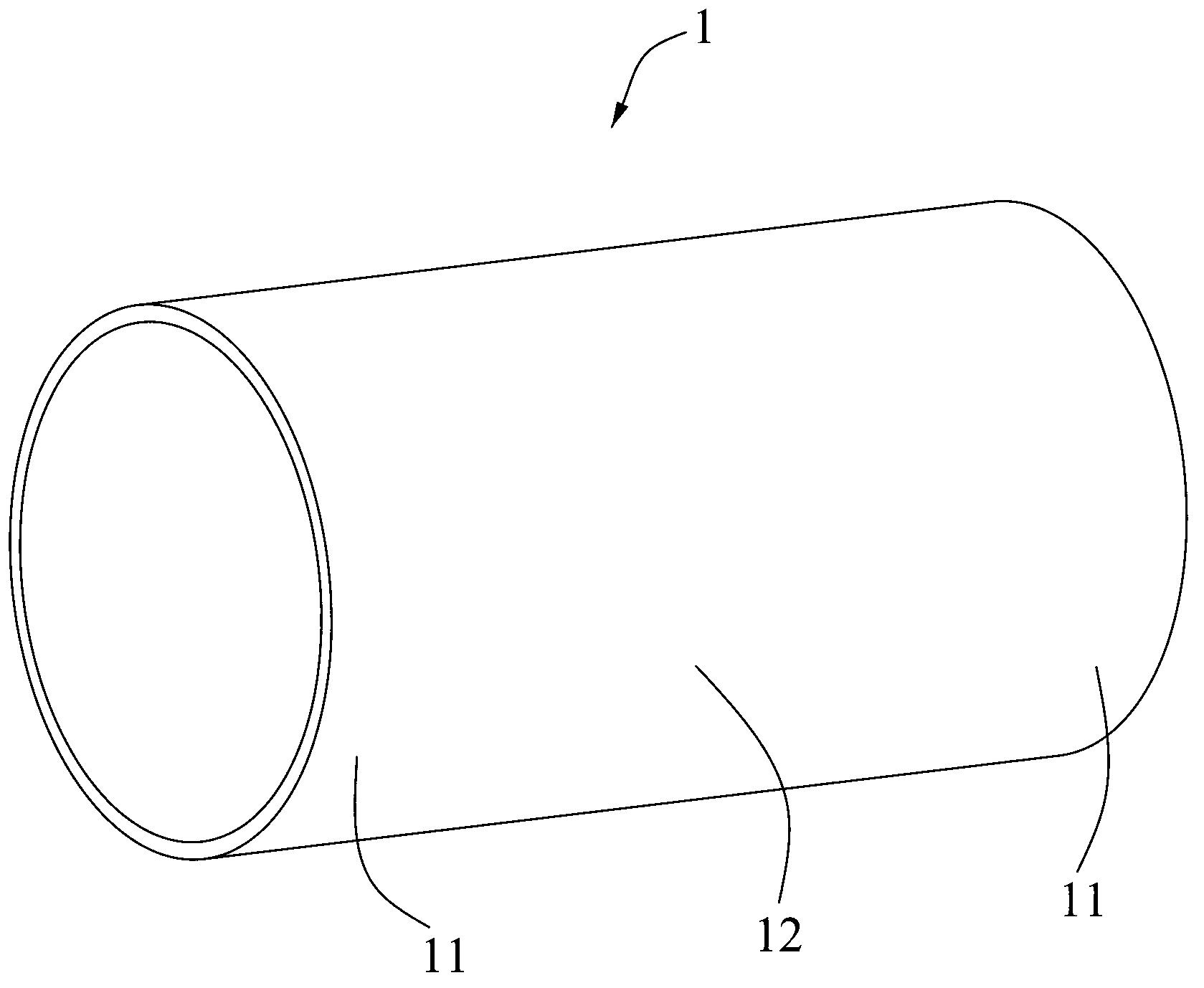

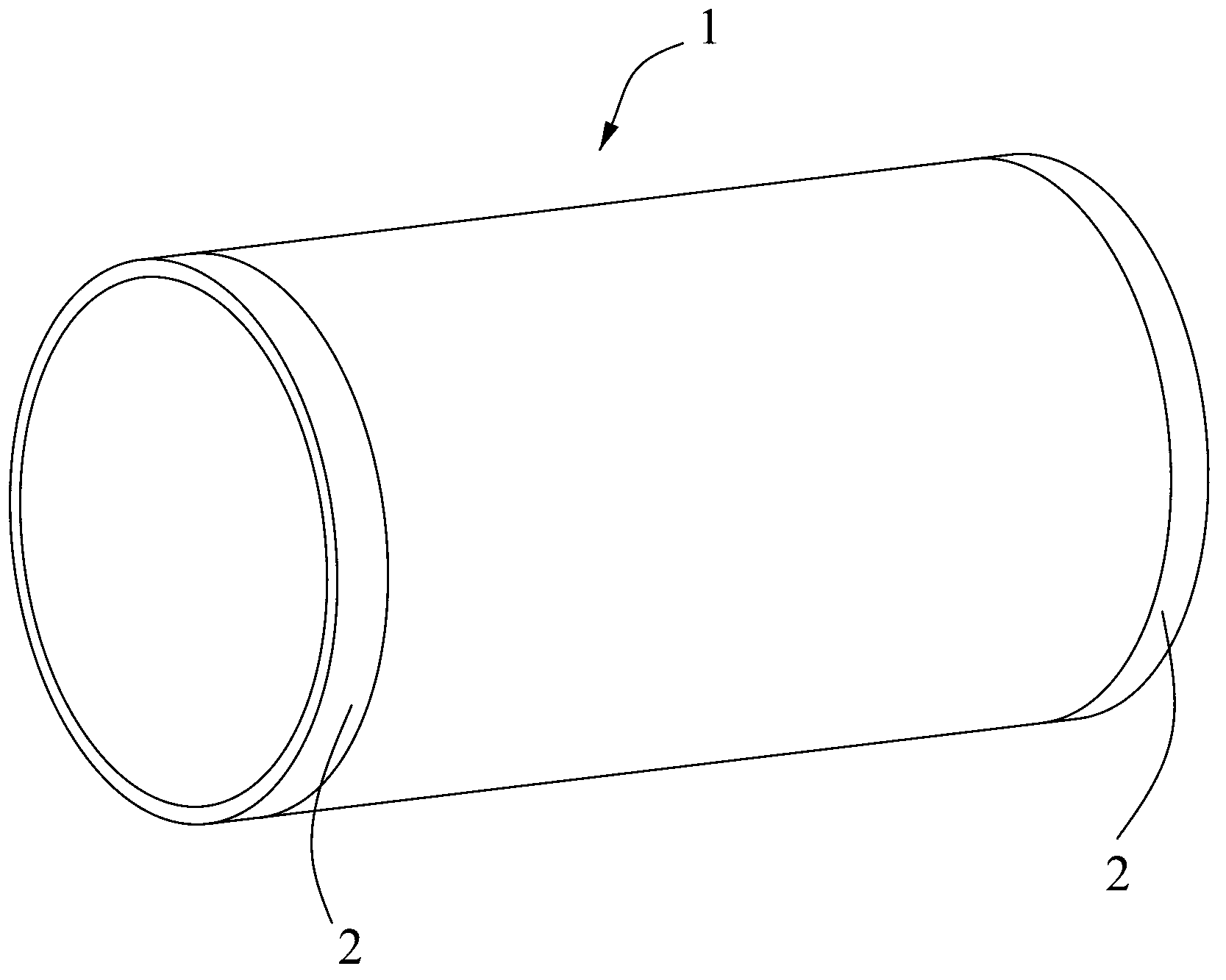

[0014] Such as Figure 2 to Figure 4 Shown, a kind of painting method of large-scale steel pipe, it comprises the following steps: 1) provide a cylindrical large-scale steel pipe 1; 2) stick scotch tape 2 on the two ends 11 of large-scale steel pipe 1; 3) all outsides of steel pipe 1 Spray paint 3; 4) Remove the scotch tape 2. Described paint 3 is black paint. The 2 places where the scotch tape is pasted are the joints between the large steel pipe 1 and another matching steel pipe. The large steel pipe 1 is used to transport oil, natural gas or sewage. The paint 3 can resist external corrosion.

[0015] Such as figure 2 As shown, the la...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap