Automatic discharging device of shuttle car for building and using method thereof

An automatic unloading device and construction technology, which is applied in the direction of inclined load-carrying vehicles, etc., can solve the problems of slow speed of scraper machine, slow construction progress, backlog of stones, etc., to increase unit transportation volume, improve use efficiency, improve Effect of unloading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

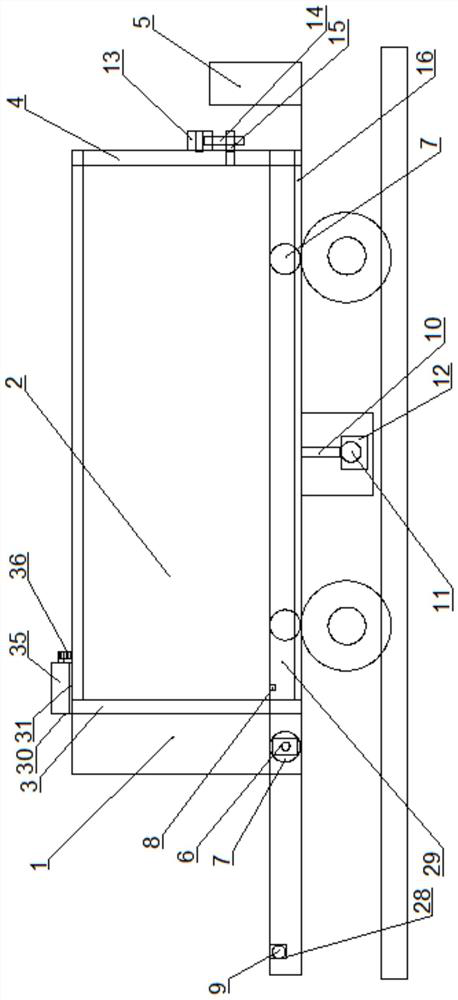

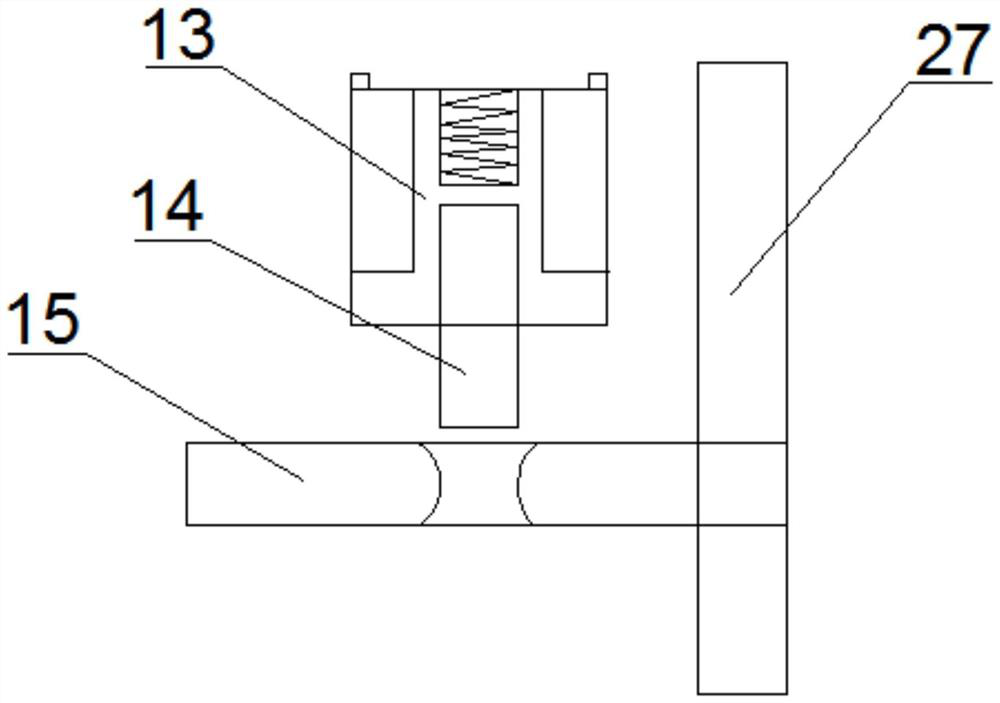

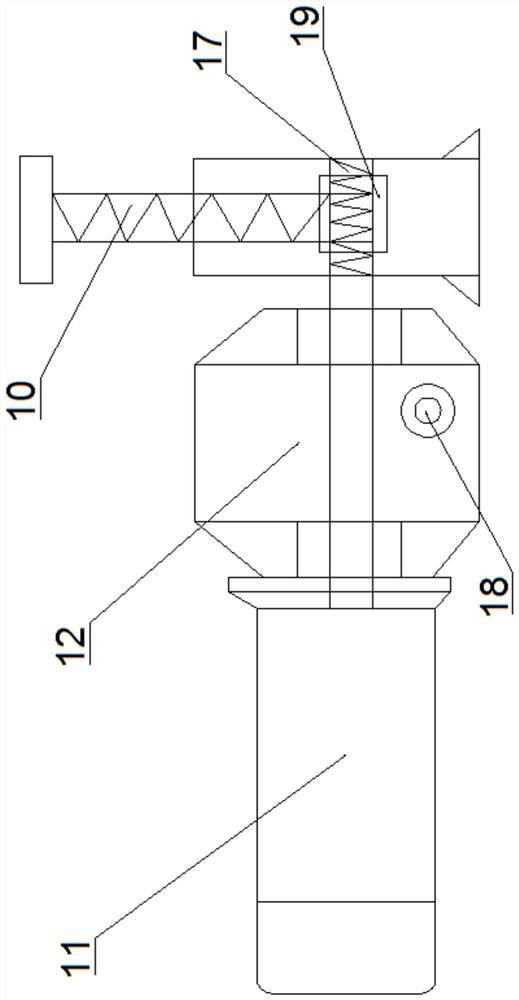

[0035] Such as Figure 1-Figure 6 As shown, a shuttle car automatic unloading device for construction includes a shuttle car main body 1, and the shuttle car main body 1 includes a front baffle 4, a rear baffle 3, a left side baffle 2 and a right side baffle 27. A control cabinet 5 is installed on one side of the front baffle 4, an electromagnetic locking device is provided on both sides below the front baffle 4, and a baffle moving device is respectively provided at the rear ends of the left side baffle 2 and the right side baffle 27. A screw lifting device is provided under the right side baffle 27, and a roller guide rail 16 is arranged between the shuttle car main body 1, the left side baffle 2 and the right side baffle 27, and the roller guide 16 is installed on the shuttle On the vehicle main body 1, a lifting device 30 is respectively arranged on the left side fender 2 and the right side fender 27, and the lifting device 30 is installed on the left side fender 2 and the...

Embodiment 2

[0051] This embodiment is different from Embodiment 1 in that the components and parts by weight of the wear-resistant plate 39 are: 12 parts of nitrile modified phenolic resin, 50 parts of hydrogenated nitrile rubber, 25 parts of polyvinyl chloride, carbonized 10 parts of silicon fiber, 5 parts of barite powder, 8 parts of graphene, 1.2 parts of vulcanizing agent, 4 parts of barium titanate, 2 parts of tributyl citrate, 1.5 parts of accelerator DM, 1 part of accelerator TMTM, anti-aging agent RD 1.5 servings.

Embodiment 3

[0053] This embodiment is different from Embodiment 2 in that: the components and parts by weight of the wear-resistant plate 39 are: 25 parts of nitrile modified phenolic resin, 30 parts of hydrogenated nitrile rubber, 10 parts of polyvinyl chloride, carbonized 15 parts of silicon fiber, 3 parts of barite powder, 2 parts of graphene, 3.5 parts of vulcanizing agent, 2 parts of barium titanate, 0.5 part of tributyl citrate, 2.5 parts of accelerator DM, 2 parts of accelerator TMTM, anti-aging agent RD 0.2 parts.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap