LED luminous lamp pole

A technology of light-emitting lamps and light poles, which is applied in the direction of light source, light source fixation, point light source, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

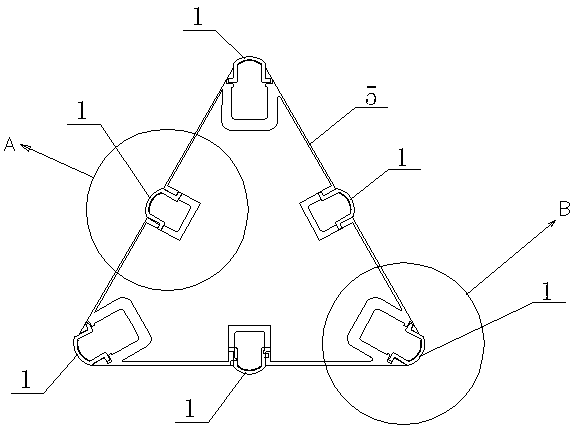

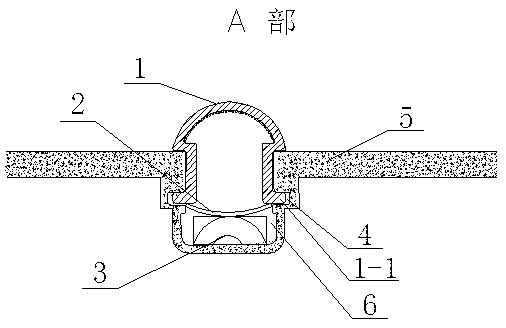

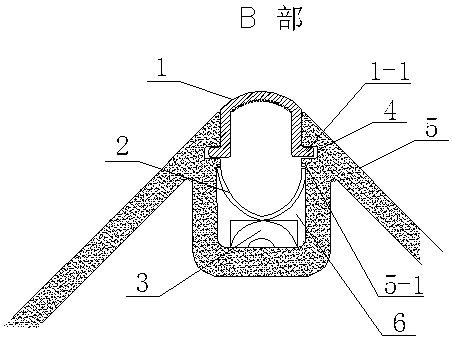

[0023] Such as figure 1 , 2 As shown in . Card slots 4 are provided on both sides of the light pole body 5 in each installation groove 6, and LED flexible light strips 3, transparent cards 2 and U-shaped light-transmitting plates 1 are respectively arranged in each installation groove 6. The light strips 3 are pasted on the light pole body 5 respectively, and the two sides of the opening end of each U-shaped light-transmitting plate 1 are separately provided with connecting flanges 1-1, and each connecting flange 1-1 is respectively arranged on the corresponding In the card slot 4, the arc sections of the three U-shaped light-transmitting plates 1 are respectively arranged outside the light pole body 5, and the three transparent cards 2 are respectively arranged on each U-shaped light-transmitting plate 1 and the corresponding LED soft light. between band 3. The two sides of the light pole body 5 in the other three mounting grooves 6 are respectively provided with bosses 5-...

Embodiment 2

[0025] Such as Figure 5 As shown, it is the second type of LED light-emitting light pole, which includes a circular light pole body 5 made of aluminum profiles, and the rest of the structure is the same as that of Embodiment 1.

[0026]

Embodiment 3

[0028] Such as Figure 6 As shown, it is the second type of LED light-emitting light pole, which includes a polygonal light pole body 5 made of aluminum profiles, and the rest of the structure is the same as that of Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap