Explosion-proof flashlight hydrostatic pressure testing apparatus

A technology for testing devices and flashlights, applied to measuring devices, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of inability to quickly fix and disassemble the shell of explosion-proof flashlights, low test efficiency, etc., to improve static Hydrostatic test efficiency, solution to test inefficiency, fast fixing and dismantling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

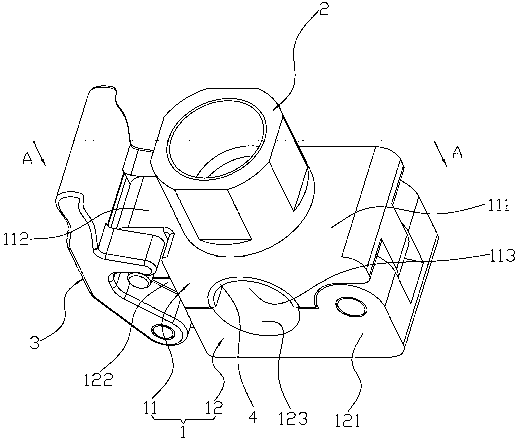

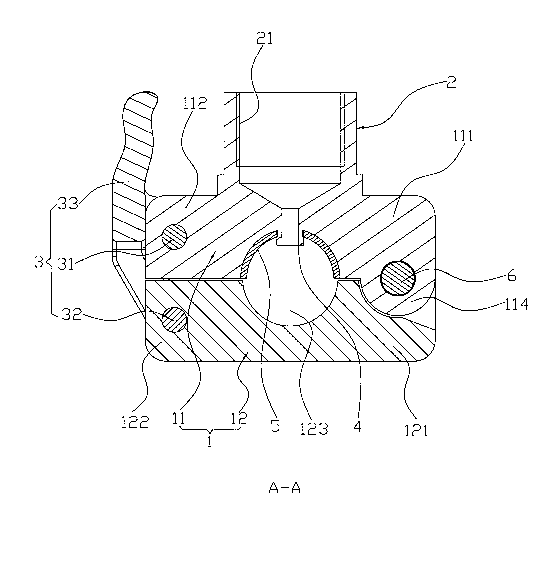

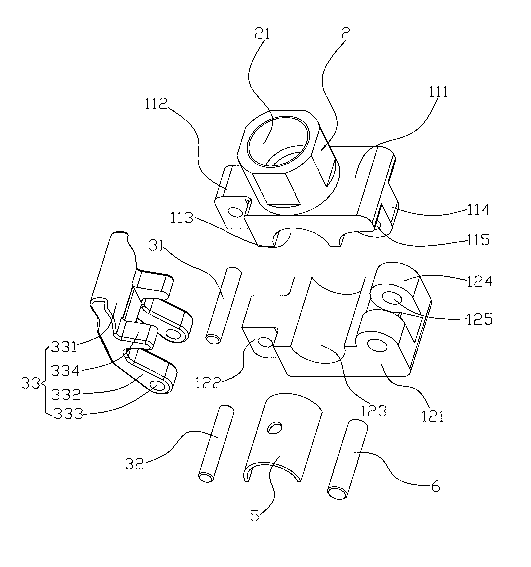

[0025] Such as figure 1 As shown, an explosion-proof flashlight hydrostatic pressure testing device provided by an embodiment of the present invention includes a compression device 1 for compressing an explosion-proof flashlight, a joint 2 connected to the compression device 1, and a pressure pump connected to the joint 2 3;

[0026] The pressing device 1 includes an upper pressing block 11 connected with the joint 2 and a lower pressing block 12 matched with the upper pressing block 11; upper circular arc grooves 113 are correspondingly opened at the joints of the upper pressing block 11 and the lower pressing block 12 and the lower arc groove 123, the upper arc groove 113 is connected with the joint 2, the upper arc groove 113 and the lower arc groove 123 cooperate to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com