Shock test device

A technology of impact test and impact parts, which is applied in the field of impact test equipment, can solve the problems of low accuracy of impact test and inability to guarantee the impact of impact hammer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to solve the problem of low accuracy of the impact test, an impact test device with high accuracy is proposed. The above-mentioned impact test device will be further elaborated below through specific embodiments and accompanying drawings.

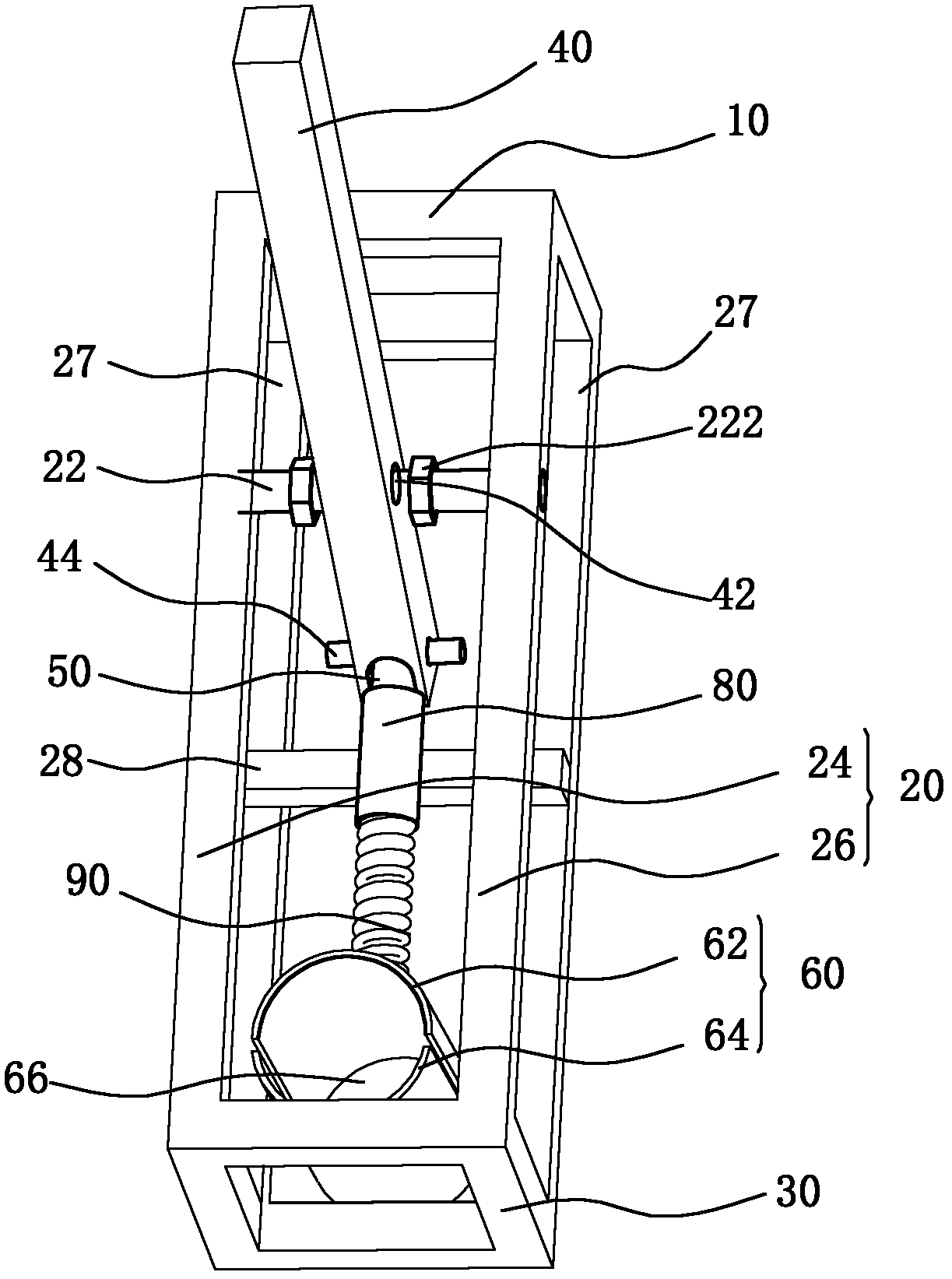

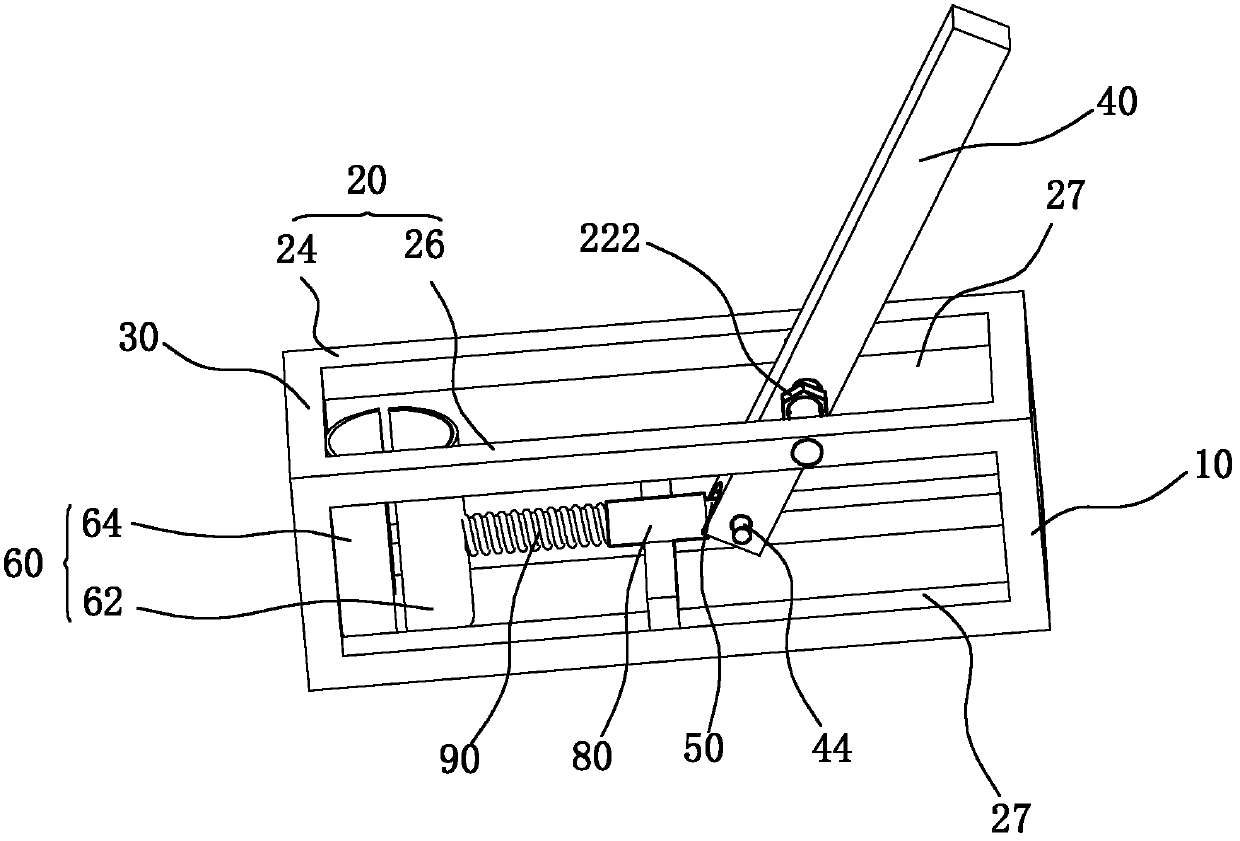

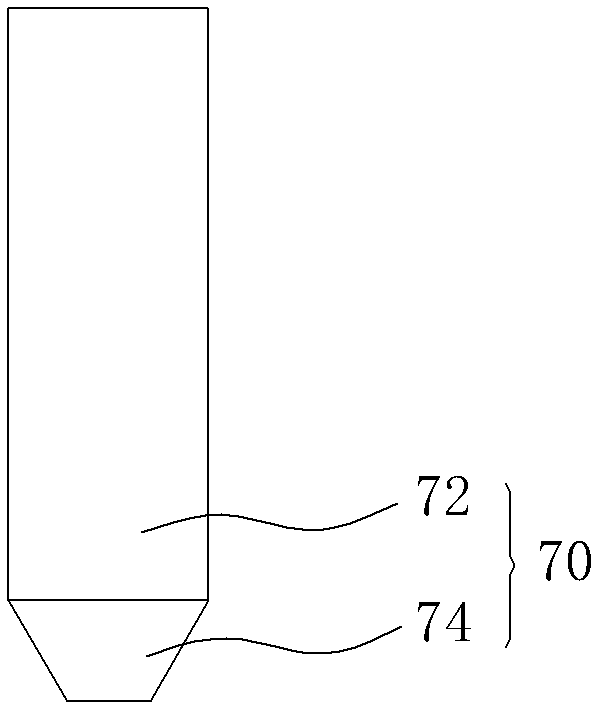

[0030] Please also refer to figure 1 , figure 2 and image 3 , The impact test device of one embodiment, the fixed base frame 10, the support member 20, the clamping base frame 30, the driving rod 40, the pull rod 50, the clamping member 60 and the impact member 70.

[0031] The fixed base frame 10 is used to carry other components of the impact test device and to fix the impact test device to a fixed object or other fixed structure, so as to perform the impact test.

[0032] The supporting member 20 is vertically fixed on the fixed base frame 10 . The support 20 is parallel to the horizontal plane. A support shaft 22 is disposed on the support member 20 . The support shaft 22 is parallel to the ground.

[0033] In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| collision energy | aaaaa | aaaaa |

| collision energy | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com