High-temperature superconducting cable alternating current tolerance testing system and method

A high-temperature superconducting and testing system technology, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as complex body structure and difficulty in meeting the testing requirements for the operation performance of high-temperature superconducting cables, and achieve simple system structure, Meet the detection requirements, easy to achieve the effect

Active Publication Date: 2013-09-25

STATE GRID CORP OF CHINA +2

View PDF7 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, considering that high-temperature superconducting cables have a more complex body structure and stronger current-carrying capacity than conventional power cables, the AC withstand voltage test system for conventional

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

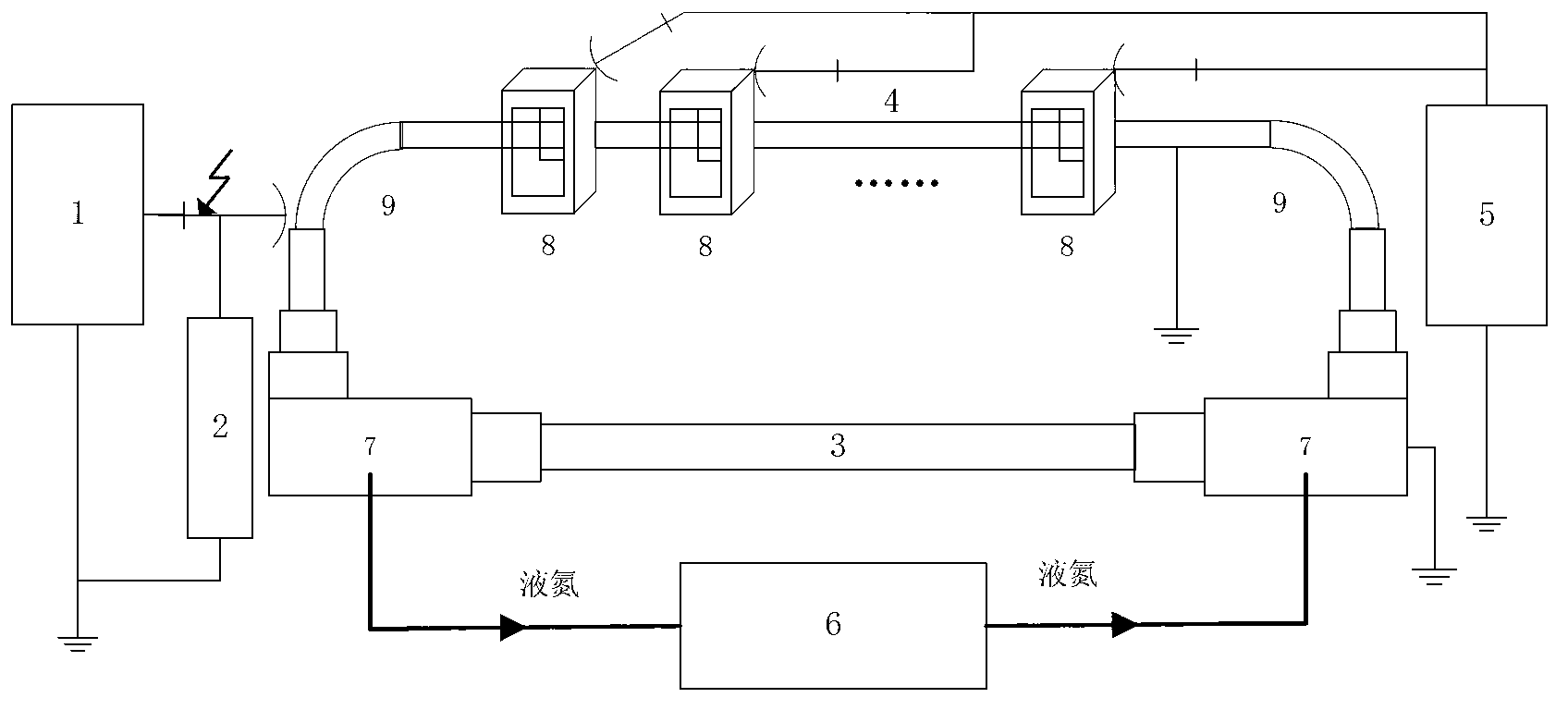

The invention relates to a high-temperature superconducting cable high-voltage testing system and method, in particular to a high-temperature superconducting cable alternating current tolerance testing system and method. A conventional power cable is connected with a tested high-temperature superconducting cable in an end-to-end mode to form a closed loop. A transformer is used as a voltage source to lift the voltage to ground of a superconducting cable wire core. A current booster is used as a current source to form a large current in an induction mode in a whole closed loop through a conventional power cable section according to the mutual inductance principle. Given that the cables are large capacitive load, a compensation reactor is arranged to balance the capacitive current in the loop, so that the voltage source works under an underloading situation far below the nominal output, the number of the front ends of the current booster is reasonably arranged, and accordingly long-time operation of the whole testing system is guaranteed, and a high-temperature superconducting cable long-time high-voltage large-current alternating current tolerance test is carried out. The whole system is simple in structure and easy to implement, and cost is saved.

Description

technical field [0001] The invention relates to a high-temperature superconducting cable high-voltage test system and a test method thereof, in particular to a high-temperature superconducting cable AC withstand test system and a test method thereof. Background technique [0002] As a new type of power transmission technology, high-temperature superconducting cable transmission technology has significant advantages such as large transmission capacity, low loss, small footprint, energy saving and environmental protection, and has become one of the important development directions of power transmission technology in the 21st century. In recent years, with the increasing maturity of superconducting application research, high-temperature superconducting cable transmission technology is gradually entering the stage of engineering application. The withstand test is one of the important test items of high-voltage equipment. The AC withstand test of high-temperature superconducting ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01R31/00

Inventor 侯经洲魏斌陈盼盼赵勇青高超

Owner STATE GRID CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com