Device and method for vacuum pressure impregnation of stator winding with frame of motor

A technology of vacuum pressure impregnation and motor stator, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators. Effect of paint space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

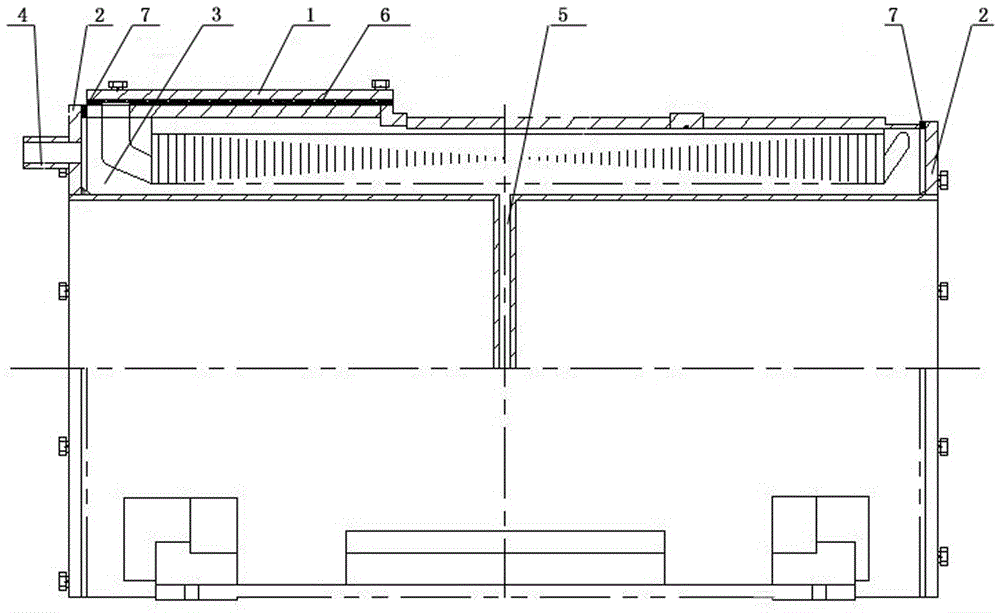

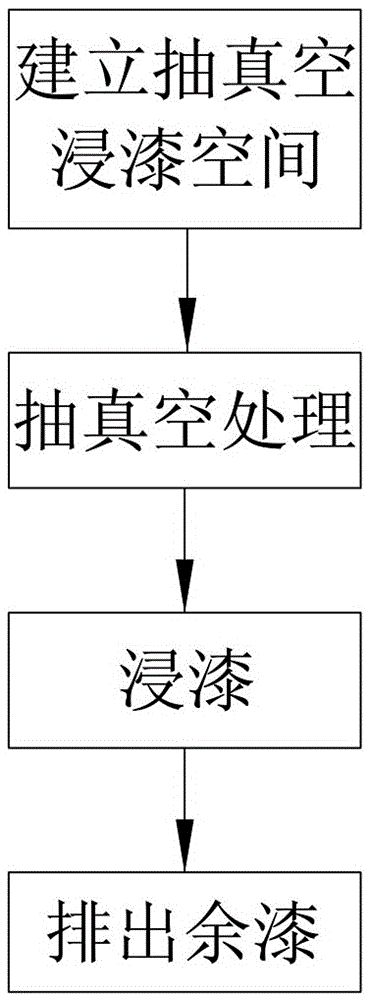

[0022] figure 1 It shows an embodiment of a vacuum pressure impregnation device for stator windings of a motor with a machine base according to the present invention. Sealing cylinder 2, sealing platen 1 at the mouth of the junction box, two sealing cylinders 2 and the motor enclose a closed vacuum immersion paint chamber 3, and at least one seal cylinder 2 is provided with a vacuum pumping paint inlet and outlet that communicates with the vacuum evacuation paint chamber 3. Interface 4. In this embodiment, the vacuuming paint inlet and outlet interface 4 is provided on the sealing cylinder 2 at the lead-out wire end of the motor stator. When using the vacuum pressure immersion paint process to process the stator winding of the motor with frame, first install the junction box mouth sealing pressure plate 1 To the junction box opening of the motor, install two sealing cylinders 2 on both ends of the motor at the same time to form a closed vacuum impregnation chamber 3, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com