Stereolithography systems and methods using internal laser modulation

A technology of lasers and lasers, applied in the field of stereolithography systems and methods using internal laser modulation, capable of solving problems such as shortening the life of lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following US patents are incorporated by reference as a whole: 5,339,323; 5,840,239; 6,001,297; 6,141,369; 6,172,996; 6,215,095; 6,590,911; 6,931,035; 7,130,321, and 7,292,387.

[0034] The following non-patent references are incorporated by reference as a whole:

[0035] "Fundamental Processes," Rapid Prototyping & Manufacturing: Fundamentals of Stereolithography , Ed: P.F. Jacobs. pp. 79-110, Society of Manufacturing Engineers, Dearborn, Mich., 1992; and

[0036] "Photopolymer Photospeed and Laser Scanning Velocity," Advances in the Imaging System, Stereolithography and other RP&M Technologies, P. F. Jacobs, pp 54-56, 110-112, Society of Manufacturing Engineers, Dearborn, Mich., 1996.

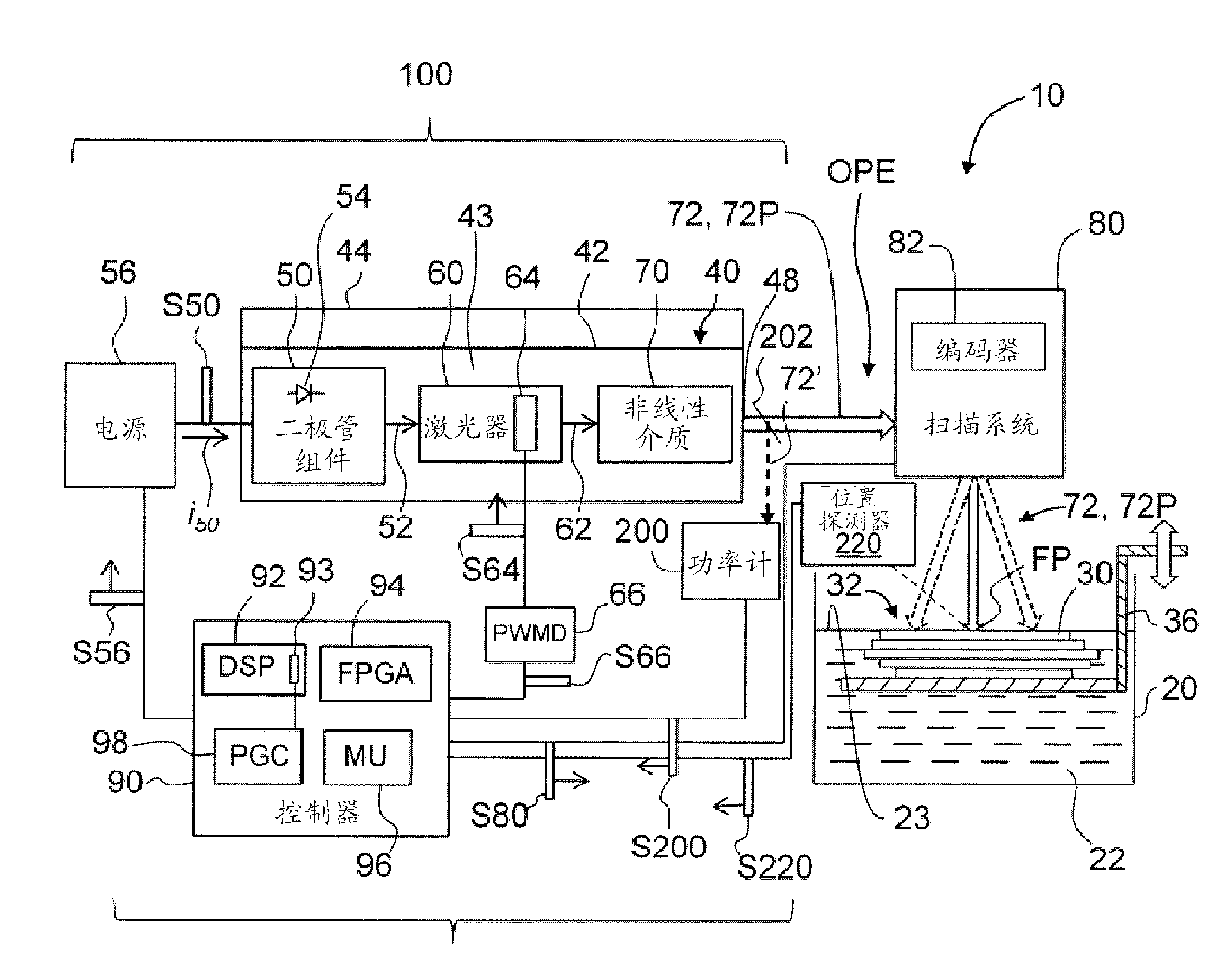

[0037] Stereolithography

[0038] Currently, stereolithography is the dominant method of rapid prototyping and manufacturing (RP&M). Stereolithography can be defined as a technique for automatically manufacturing three-dimensional objects from fluid-like building materials, which utilizes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com