Tubular beams for automotive structures with improved crash performance

A crossbeam and bumper technology, applied to vehicle components, vehicle safety arrangements, bumpers, etc., can solve problems such as increasing the weight of bumpers, going against market trends, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

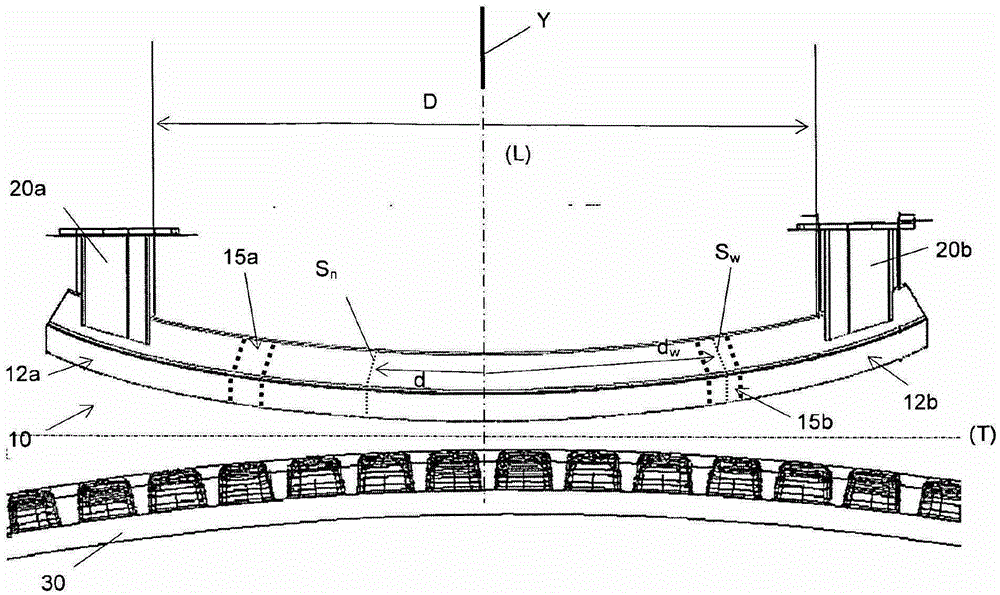

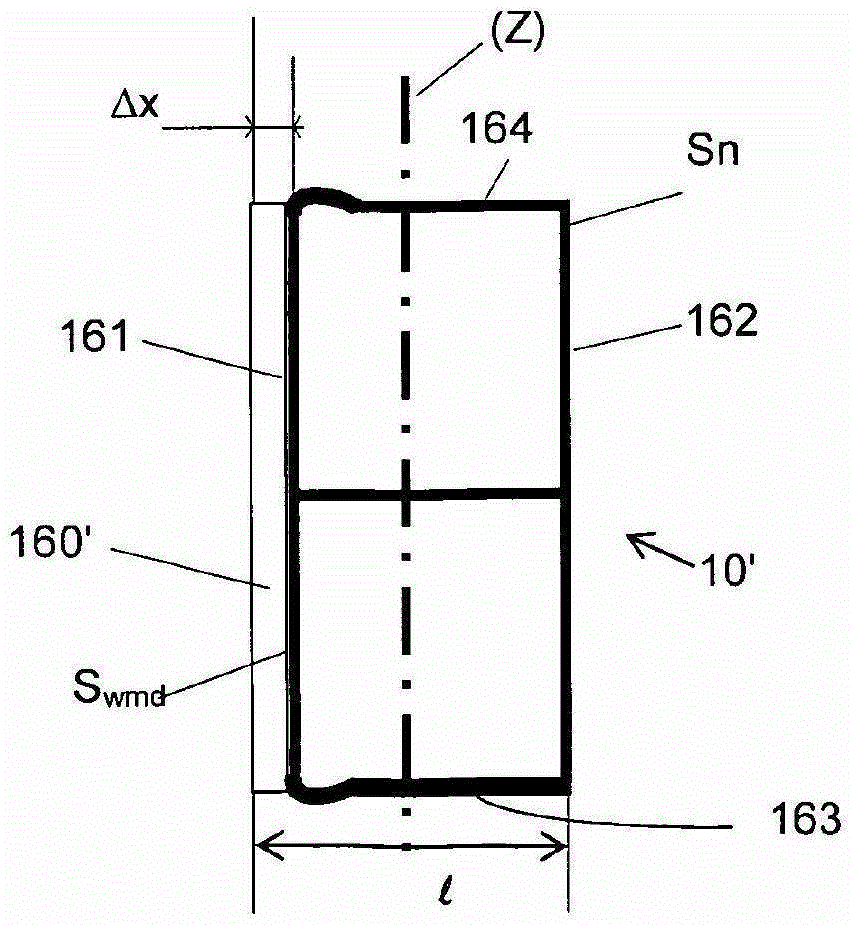

[0039] Embodiment 1: ( image 3 and Figure 4 , Figure 5 variant)

[0040] image 3 and Figure 4 A first embodiment of the invention is shown: the bumper beam (10') is made from an extruded aluminum alloy profile which has been bent to have the intended general shape of the bumper; and the weakened area has passed through the Made by plastic deformation of the front wall. The cross-section of the profile comprises a front wall (161), a rear wall (162), a top wall (164) and a bottom wall (162).

[0041] In the weakened areas (15'a and 15'b), the front wall (161) is pushed towards the bumper by: placing a punch over the entire height of said front wall; and, actuating said punch, so that it moves a distance ΔX towards the profile, creating a depression (160'). In order to obtain a continuous slight change in cross-section in the weakened area to prevent the beam from breaking suddenly in the transition zone, the indenter has a curved working surface with a radius of cur...

Embodiment 2

[0043] Embodiment 2: ( Figure 6 )

[0044] Figure 6 Another embodiment of the invention is shown: the bumper beam (10''') is made from an extruded aluminum alloy profile that has been bent to have the intended general shape of the bumper; and, the weakened area has been passed A front portion of a beam is machined and includes a front wall and portions of top and bottom walls immediately adjacent the front wall. The geometry of the machined surface emulates the recessed bracket-type shape of the first embodiment, with the difference that there is no longer a front wall (161) in the weakened area, so that the recess (160) is replaced by a hole communicating with the interior of the hollow profile ( 17) Instead.

[0045] Depending on the vehicle to be equipped with the bumper, the beam of the bumper is bent with one or more radii of curvature and the distance D between the attachment areas (12a, 12b) is approximately between 1000mm and 2000mm. The weakened area is approxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com