Analog measuring probe for machine tool equipment and method of operation

A technology for simulating probes and equipment, applied in the field of measuring probes, which can solve problems such as inaccurate measurement and inability of probes to work, and achieve the effect of avoiding overvoltage or undervoltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

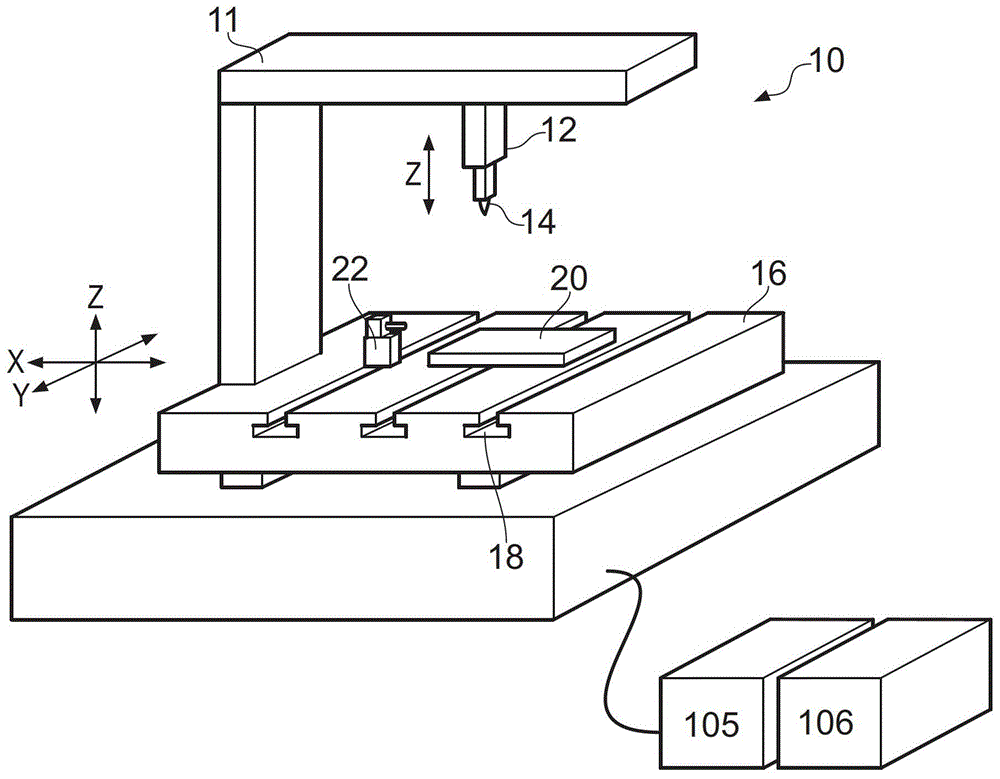

[0094] Reference figure 1 The conventional machine tool equipment 10 includes a bed 16 on which a workpiece 20 and any machine tool accessories such as a tool adjuster 22 can be installed. The machine tool 10 also includes a frame 11 supporting a spindle 12 on which a tool 14 can be mounted.

[0095] The spindle 12 and the machine bed 16 can move relative to each other along three orthogonal directions X, Y, and Z in the working space of the machine tool device 10. In this example, the mandrel 12 and the cutter 14 can move in the Z direction, and the table can move in the X and Y directions. This movement is achieved by X, Y and Z drives (not shown) controlled by the machine tool controller 105 or any suitable computer and interface. A measurement scale reading device (not shown) is provided on each of the respective X, Y, and Z axes in order to measure the relative movement of the mandrel 12 in each direction. Therefore, the mandrel 12 and the bed 16 can accurately move relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com