Fixed polishing machine

A polishing machine, fixed technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve problems affecting production efficiency, polishing machine affecting polishing quality, etc., to increase smoothness and flatness , Avoid multiple processing and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

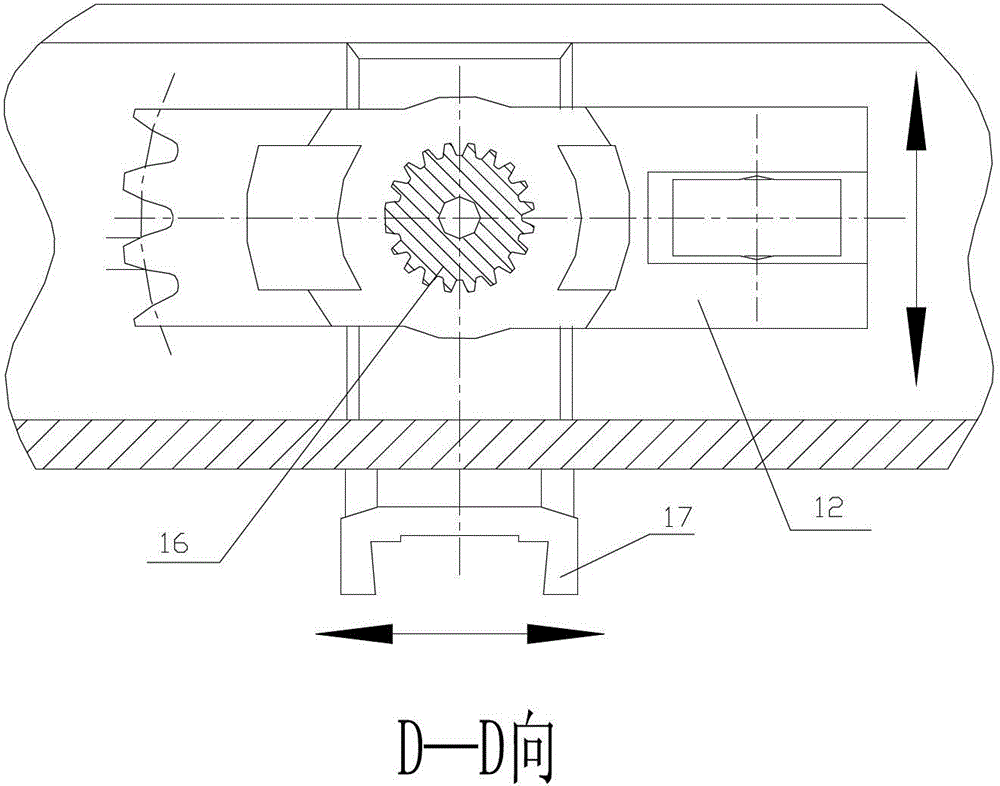

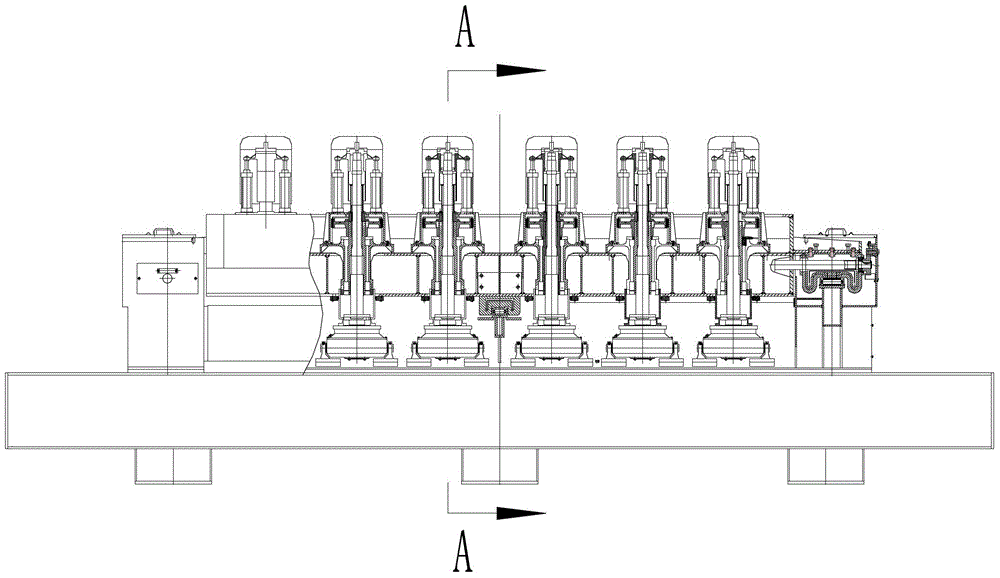

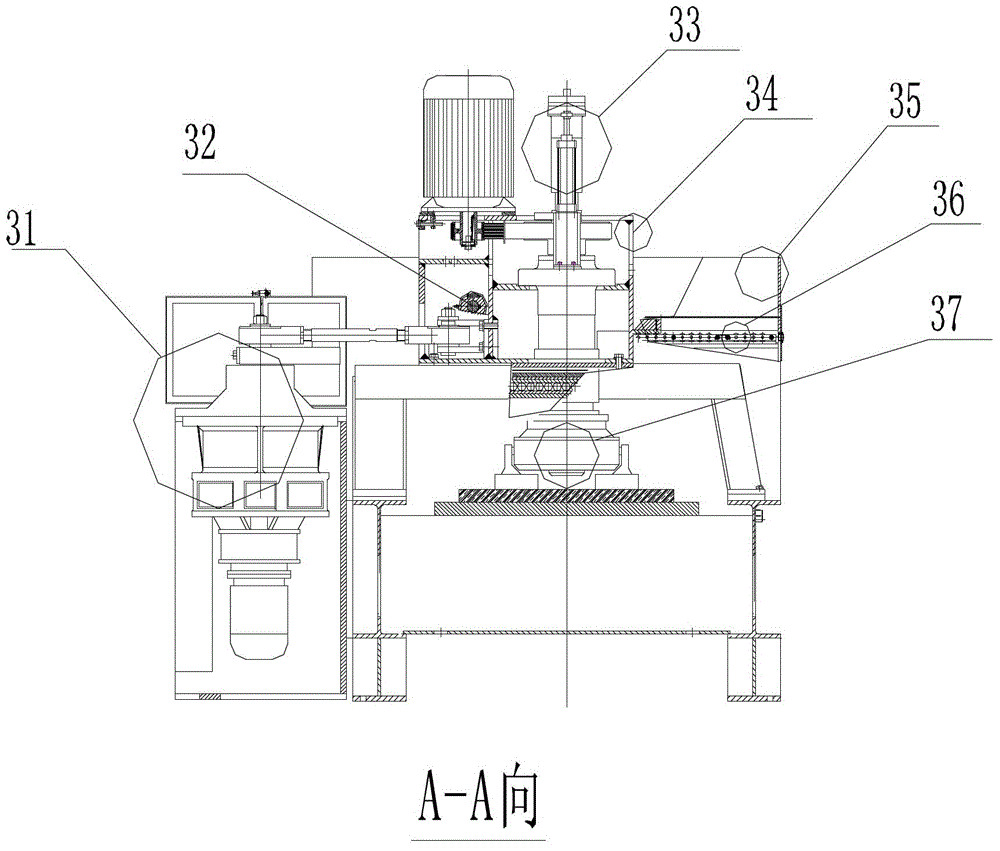

[0016] A fixed polishing machine includes a base 27 , a polishing device 21 , a support base 23 and a beam 22 . Such as Figure 2B As shown, the base 27 includes a workbench for processing materials 28 below 800 mm. The support base 23 is fixed on the front and rear sides of the base 27 . The beam 22 is located on the upper part of the base 1 and is fixed on the supporting base 23 . The polishing device 21 is fixed on the crossbeam 22. The polishing device 21 includes a grinding disc 24 with an outer diameter greater than 800mm, a motor 30 that drives the grinding disc to rotate, and an upper assembly 28 that connects the motor and the grinding disc. The grinding disc 24 also includes a processing part located at the bottom of the grinding disc—a grinding block 26, the grinding block 26 is fixed on the grinding block seat 25 through a V-shaped bayonet; On the spline shaft that can rotate on the outside.

[0017] Such as Figure 2A As shown, multiple groups of mold throwin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com