Fulcrum-limiting two-stage floating type flexible retention mechanism for grinding equipment

A holding mechanism, floating technology, applied in grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of uneven grinding force, poor grinding and polishing effect, and reduced surface quality, and achieve extended use. Longevity, improved flatness and smoothness, and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention is a two-stage floating flexible holding mechanism with fulcrum limit for grinding equipment, which can make the grinding head fully contact with the uneven surface at all times, effectively eliminate or reduce the uneven grinding force of the tool and the partial grinding of the tool. Improve the flatness and smoothness of the polished surface.

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

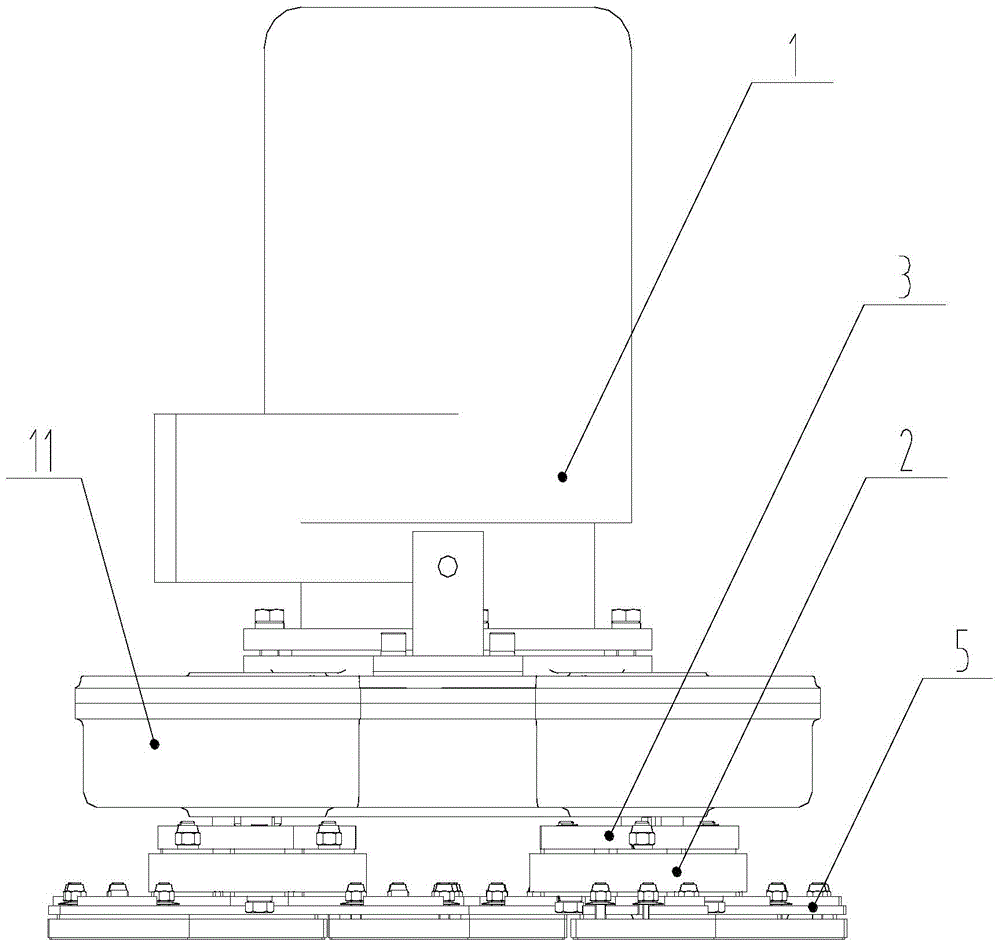

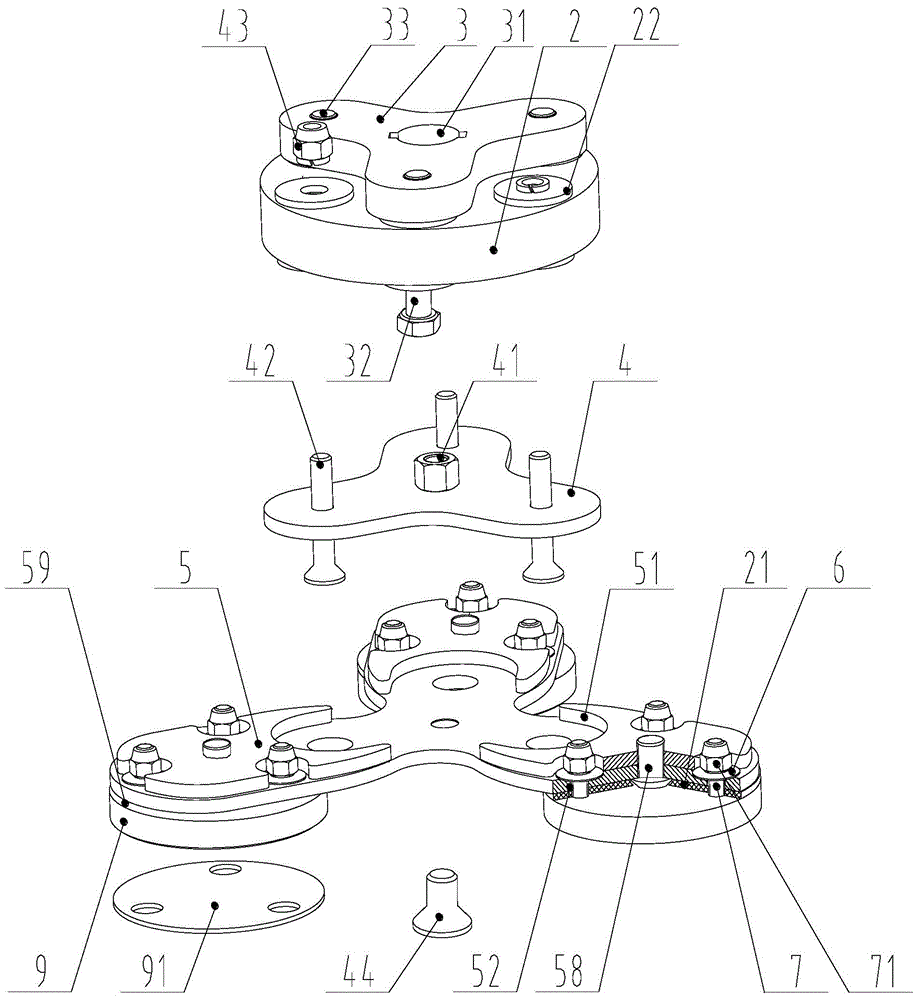

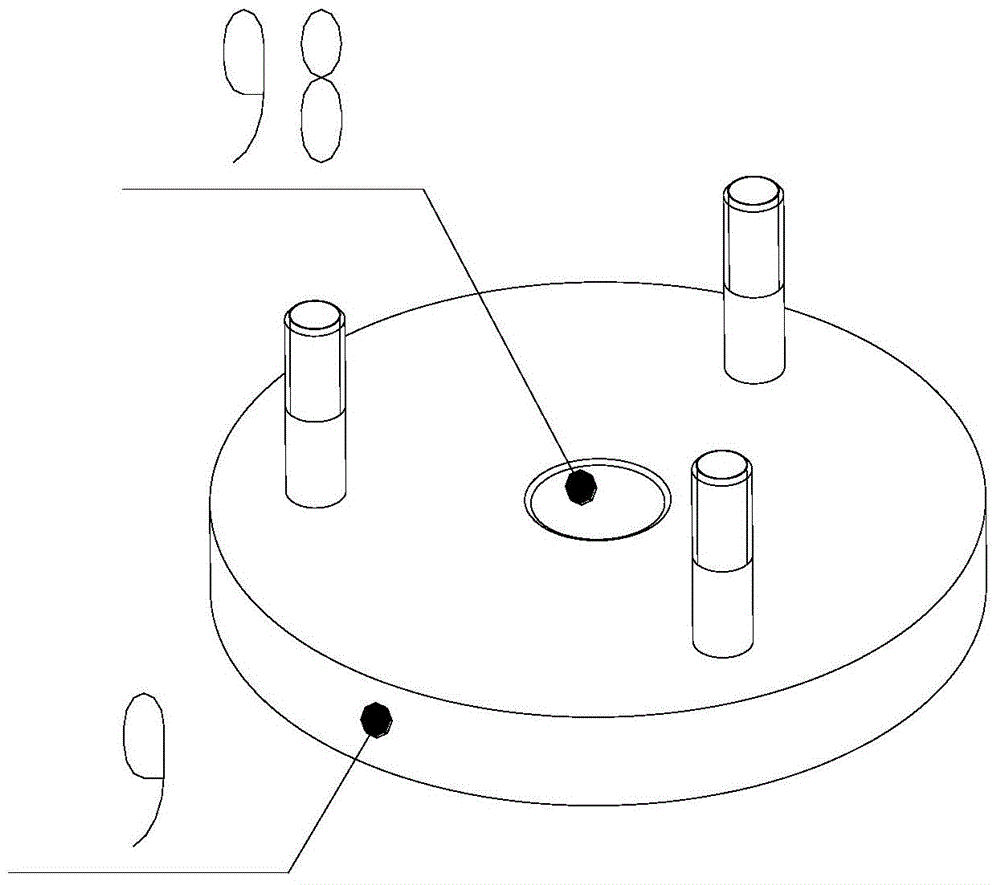

[0025] Specific examples, such as Figure 1 to Figure 4 As shown, the fulcrum limit floating flexible holding mechanism of the present invention is connected on a plurality of power output sub-shafts below the power take-off mechanism 11, driven by the power equipment 1 above the power take-off mechanism 11, the power equipment 1 is a motor, and the power The output mechanism 11 divides the power input by the motor into multiple partial powers and outputs them from the power output shafts, and then drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com