Surface plating technique for polymer material product

A polymer material and surface coating technology, applied in the field of material science, can solve problems such as poor gloss and appearance, non-conforming to environmental protection, serious environmental pollution, etc., to improve smoothness and flatness, improve grades and added value, and improve The effect of acid and alkali resistance and corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

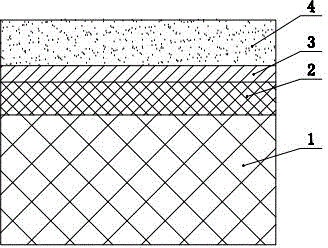

Image

Examples

Embodiment 1

[0027] The selected polymer material product is ABS polymer plastic shower head, and the specific treatment process is: (1) Clean the surface of the shower head through an ultrasonic cleaning device; (2) Epoxy resin that will be diluted by monomer polymer The polymer is covered on the surface of the cleaned shower head by spraying and immersion treatment, so as to form a 1-10 micron epoxy resin polymer primer layer on the surface of the shower head, so that the irregular or rough surface shower head can be modified into The surface is smooth and flat, and then heated by ultraviolet radiation to cure the epoxy resin polymer primer layer to form a solid-state hardened surface layer to be coated; (3) Send the above-mentioned cured products into the equipment equipped with coating components and ion sources In the vacuum chamber, vacuumize and preheat to 100 degrees. When the vacuum degree reaches 7*10e-3, enter 0.1Pa argon gas, turn on the ion source to activate and modify the sur...

Embodiment 2

[0029] The selected polymer material product is also ABS polymer plastic shower head. The specific treatment process is: (1) Clean the surface of the shower head by ultrasonic cleaning device; (2) Polyurethane resin that will be diluted by monomer polymer The polymer is covered on the surface of the cleaned shower head by spraying and immersion treatment, so as to form a 1-10 micron polyurethane resin polymer primer layer on the shower head surface, which can modify the irregular or rough surface of the shower head to the surface Clean and flat surface, and then heated by ultraviolet radiation to cure the polyurethane resin polymer primer layer to form a solid hardened surface layer to be coated; (3) send the above cured products into a vacuum equipped with coating components and ion sources In the room, vacuumize and preheat to 150 degrees. When the vacuum degree reaches 7*10e-3, introduce 0.5Pa argon gas, and turn on the ion source to activate and modify the surface of the pr...

Embodiment 3

[0031] The selected polymer material product is also ABS polymer plastic shower head. The specific treatment process is: (1) Clean the surface of the shower head by ultrasonic cleaning device; (2) Polyurethane resin that will be diluted by monomer polymer The polymer is covered on the surface of the cleaned shower head by spraying and immersion treatment, so as to form a 1-10 micron polyurethane resin polymer primer layer on the shower head surface, which can modify the irregular or rough surface of the shower head to the surface Clean and flat surface, and then heated by ultraviolet radiation to cure the polyurethane resin polymer primer layer to form a solid hardened surface layer to be coated; (3) send the above cured products into a vacuum equipped with coating components and ion sources In the room, vacuumize and preheat to 200 degrees. When the vacuum degree reaches 7*10e-3, introduce 2Pa nitrogen gas, and turn on the ion source to activate and modify the surface of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com