Processing device based on non-Newtonian fluid shear thickening mechanism polishing method

A non-Newtonian fluid, thickening mechanism technology, used in surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high cost, poor polishing effect, poor quality control of workpiece edge polishing, etc. Strong processing capacity, cost reduction, control of processing dwell time and the effect of positive pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further illustrate the present invention below in conjunction with accompanying drawing

[0024] Referring to the attached picture:

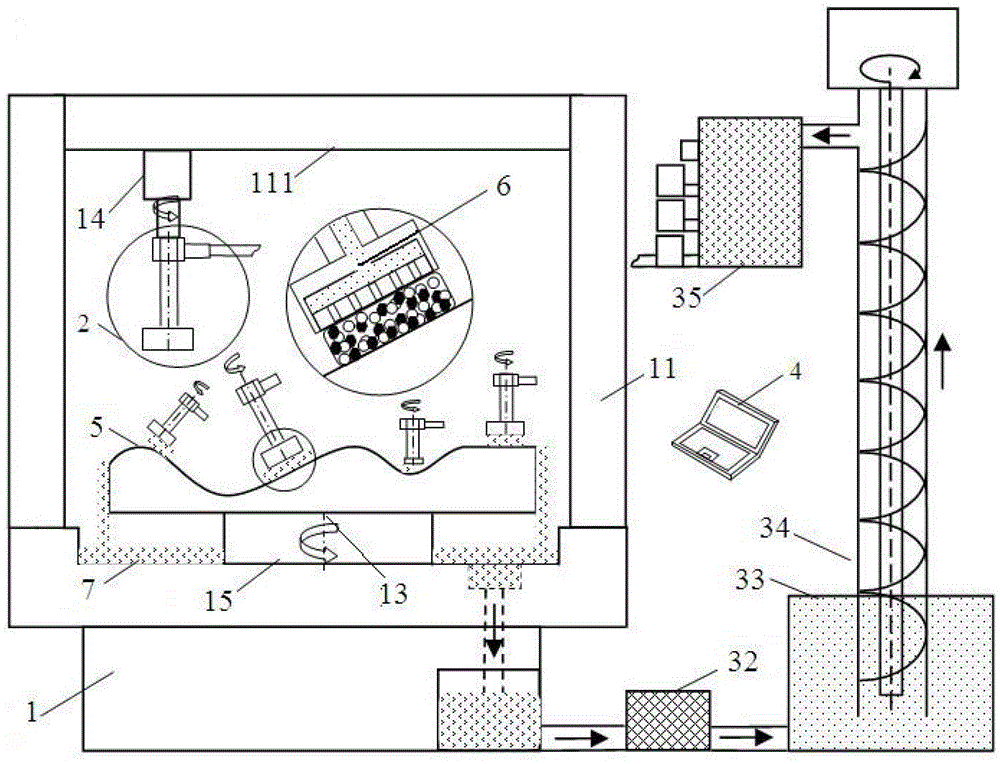

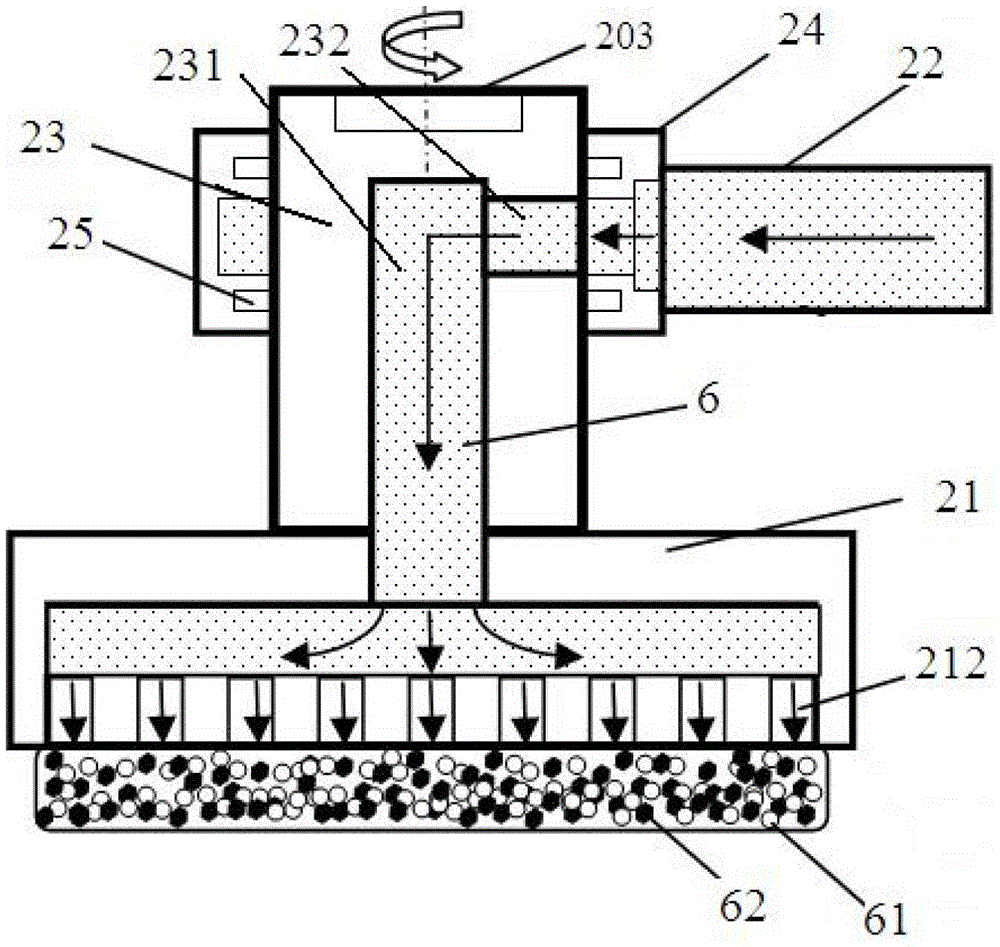

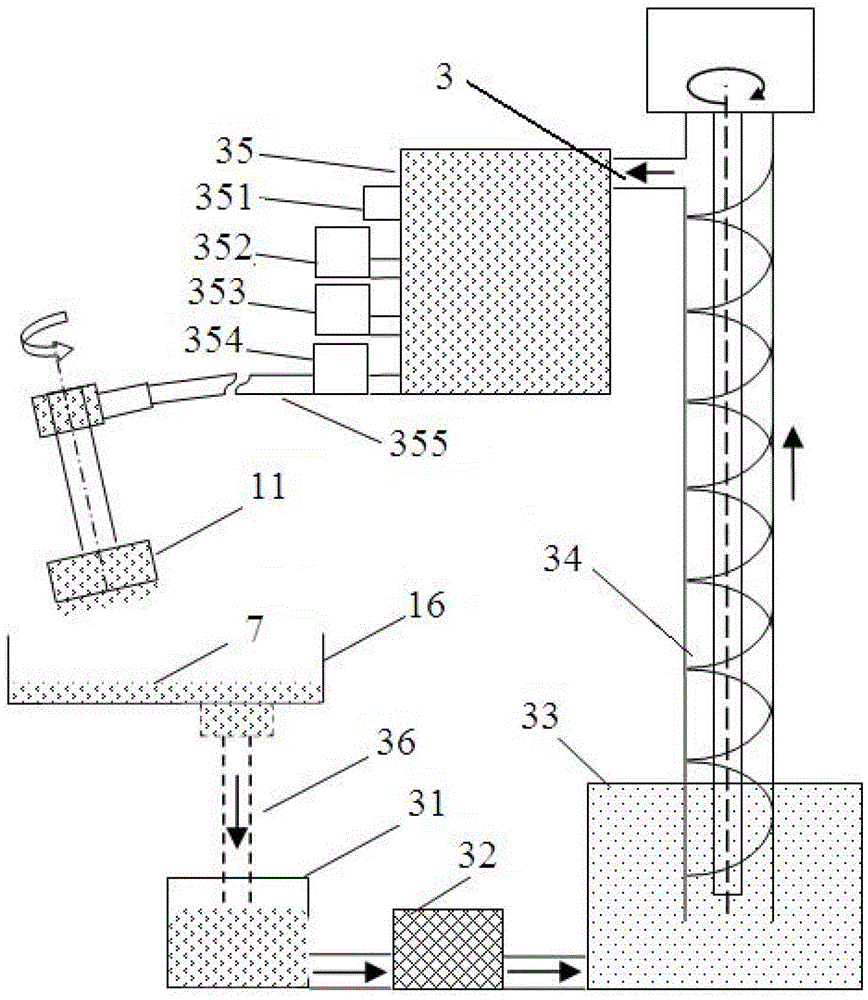

[0025] The processing device based on the non-Newtonian fluid shear thickening mechanism polishing method according to the present invention includes a workbench 1, a polishing tool system 2, an abrasive liquid circulation device 3, and a computer control module 4. The polishing tool 2 is installed on the On the gantry 11 on the above-mentioned workbench 1, the inlet of the described abrasive liquid circulation device 3 communicates with the abrasive material return port 12 provided on the above-mentioned workbench 1, and the described workbench 1, polishing tool 2, abrasive The liquid circulation device 3 is respectively connected with the computer control module 4 .

[0026] The workbench 1 has workpiece fixtures for clamping workpieces of various sizes, and has a plurality of degrees of freedom. Under the control of the computer control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com