Puller

A technology of pulling seat and screw rod, which is applied to pulling horses. It can solve the problems of low work efficiency, heavy workload, damage to the pulled objects, etc., and achieve the effect of good versatility, small workload and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

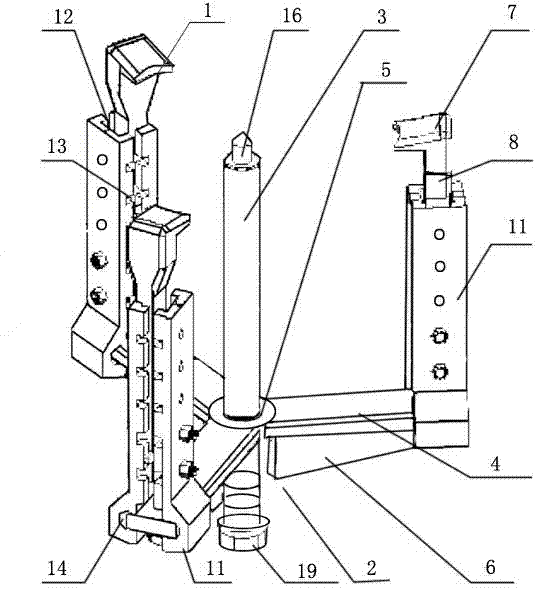

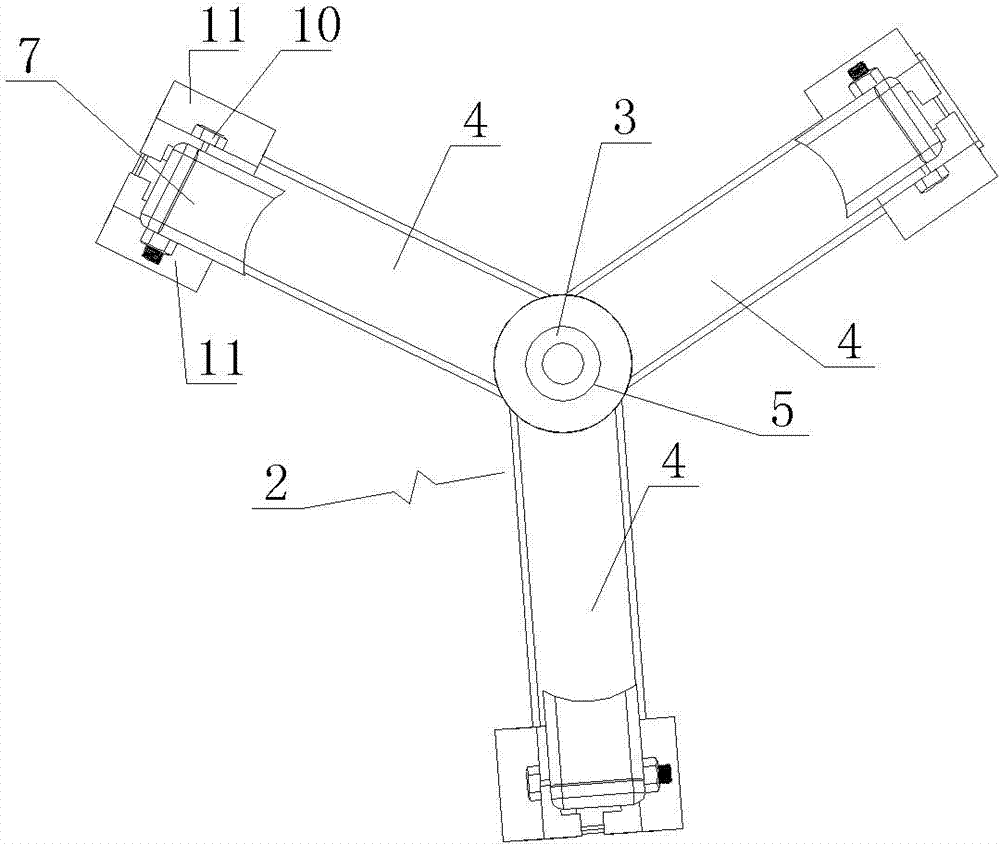

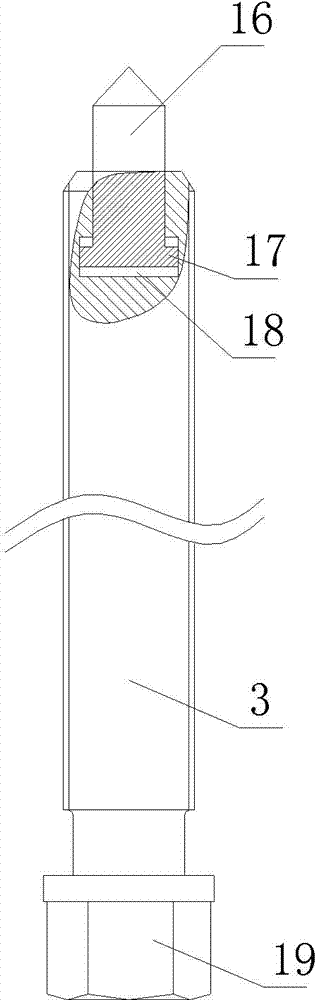

[0014] See figure 1 , figure 2 , image 3 , Figure 4 , which includes three pull feet 1, a pull seat 2, and a screw rod 3, the center of the pull seat 2 is provided with a screw rod 3, and the three pull feet 1 are evenly distributed on the pull seat 2, and the pull seat The bottom of 2 has three pedestals 4, and its center is provided with threaded hole 5, and three pedestals 4 circumferential direction are evenly distributed on the periphery of described threaded hole 5, and the bottom surface of each described pedestal 4 is provided with downward convex The positioning guide rail 6, the screw rod 3 runs through the threaded hole 5, the pull foot 1 includes the upper claw 7, the middle vertical rod 8, the bottom positioning boss 9, and the fixing bolt 10 is connected to the pair of connecting pieces 11. Form an upper vertical groove 12, a uniform longitudinal positioning groove 13, and a lower chute 14, the upper vertical groove 12 is clamped with the middle vertical ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com