Broom head, mold for preparing broom head and broom head processing technology

A technology of broom head and mould, which is applied in cleaning carpets, floors, cleaning equipment, etc. It can solve the problems of increased cost, high cost investment, short service life, etc., and achieves improved yield and pass rate, reduced equipment investment cost, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

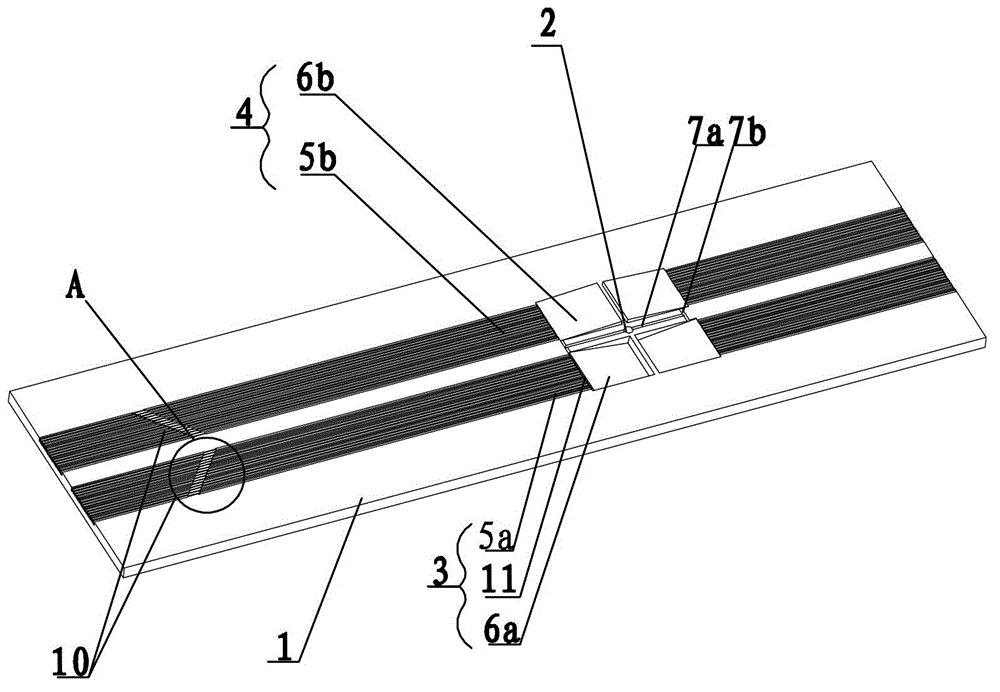

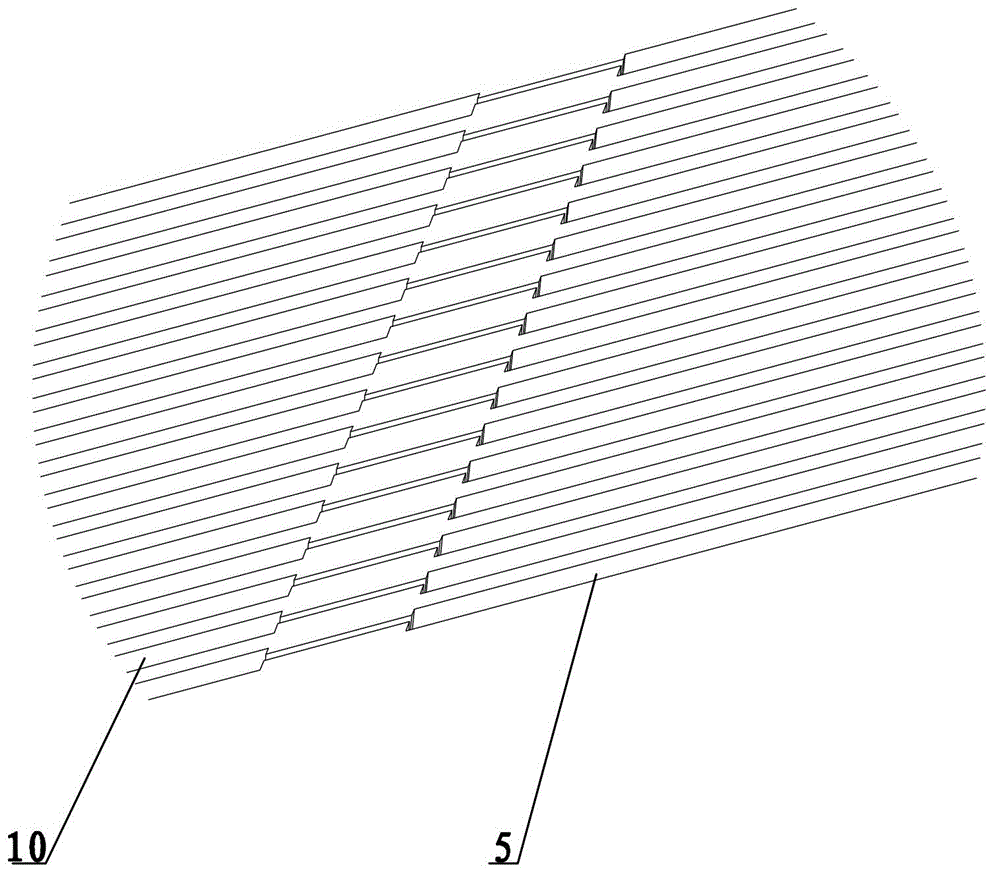

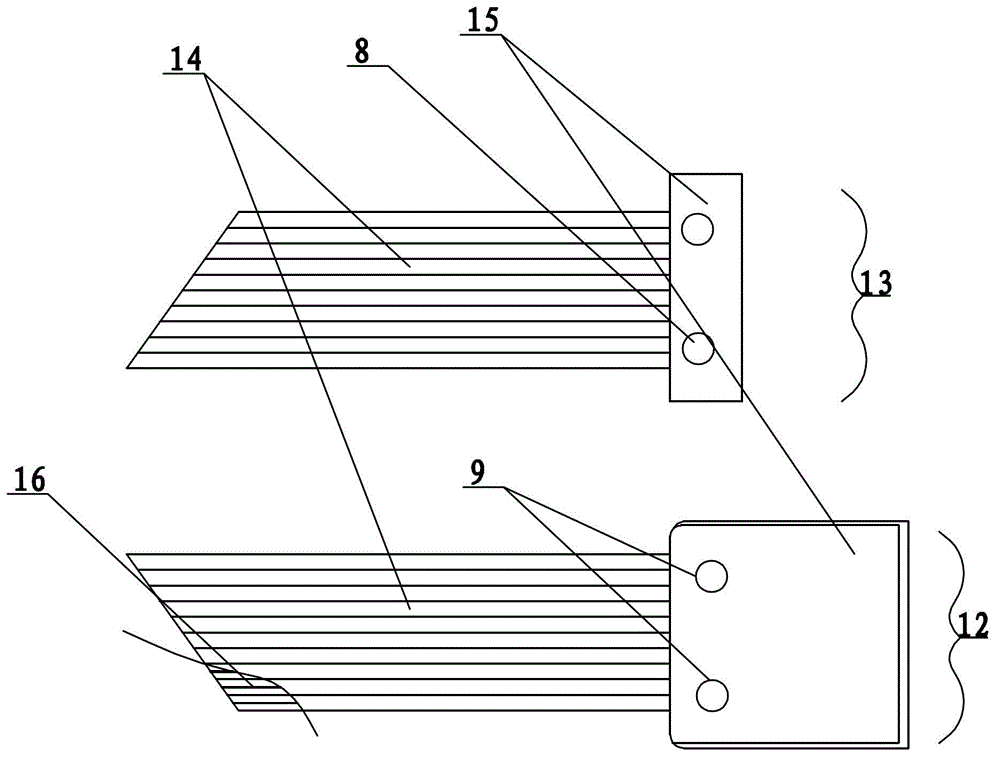

[0043] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that: in terms of the structure of the broom head mold, the injection hole 12 is located between the main mold and the secondary mold, and is located on the extension line of the transition road 11, and the injection hole Runner 7 is arranged on both sides of 12, and injection hole 12 is located in the middle of runner 7, and injection hole 12 connects the transition channel 11 of main mold and the groove 2 6b of secondary mold through the runner 7 of its two sides; In terms of processing technology, step In (3), the injection pressure of the material in the molten state is 7~10KPa, and the injection flow rate is 60~80cm 2 / s, the injection temperature is 250~300°C, and in step (4), the cooling time for cooling and solidification molding is 20~30s; in terms of the structure of the broom head, the reinforcing rib 16 is made of nylon, and the length of the reinforci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com