Shielding bag

A shielding bag and shielding metal technology, applied in the field of shielding bags, can solve problems such as component damage, product failure, economic loss, etc., and achieve the effect of eliminating static electricity, facilitating observation, and solving static electricity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

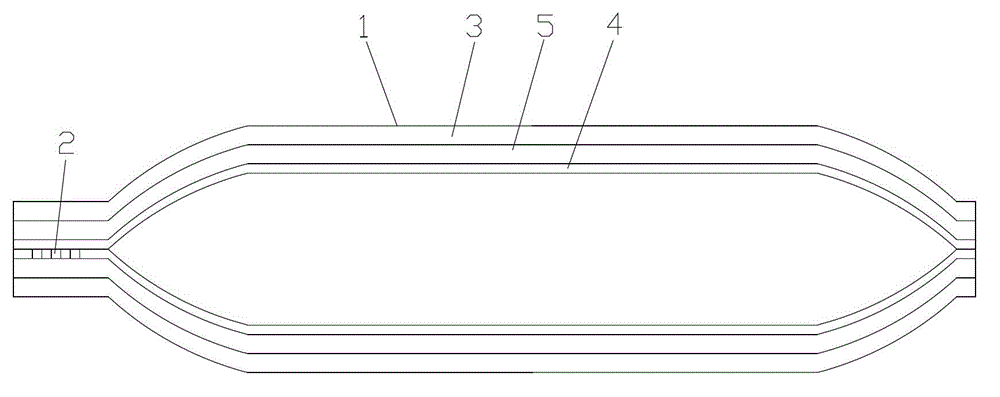

[0020] as attached figure 1 As shown in the shielding bag of the present invention, the bag body 1 is made of two pieces of shielding material heat-sealed on three sides; the bag opening of the bag body 1 is sealed by a sealing port 2; the shielding material includes Transparent base layer 3, endoplasmic layer 5 and shielding metal layer 4; said transparent base layer 3 and endoplasmic layer 5 are bonded to each other; one side of said endoplasmic layer 5 is coated with shielding metal layer 4; said transparent base layer 3 is Polyesterene; the endoplasmic layer 5 is polyethylene or polypropylene; the shielding metal layer 4 is aluminum powder.

Embodiment 2

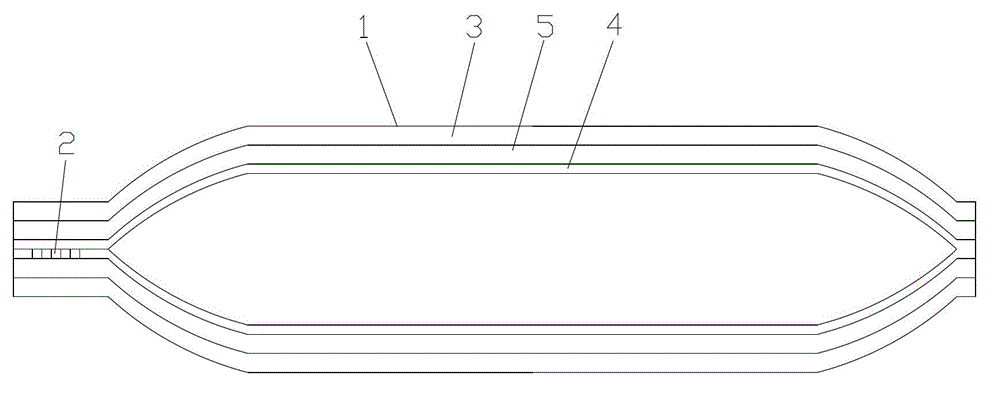

[0022] as attached figure 2 A shielding bag according to the present invention is shown, the bag body 1 is made of a piece of shielding material folded in half and then heat-sealed on both sides; the bag opening of the bag body 1 is sealed by a sealing port 2; the shielding material includes Transparent base layer 3, endoplasmic layer 5 and shielding metal layer 4; said transparent base layer 3 and endoplasmic layer 5 are bonded to each other; one side of said endoplasmic layer 5 is coated with shielding metal layer 4; said transparent base layer 3 is Polyesterene; the endoplasmic layer 5 is polyethylene or polypropylene; the shielding metal layer 4 is aluminum powder.

[0023] When the shielding bag of the present invention is used, electronic components are placed in the shielding bag, and then the mouth of the bag is sealed with a sealing opening.

[0024] In the shielding bag of the present invention, the body of the bag is made of two pieces of shielding material heat-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com