Redirection hopper device of stacker

A technology of a hopper device and a stacker, which is applied in the field of stackers, can solve the problems of fast material transmission, troublesome replacement of wear-resistant linings, deviation of tapes, etc., so as to reduce the cost of wearing parts and solve deviation and damage. , Reasonable effect of structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

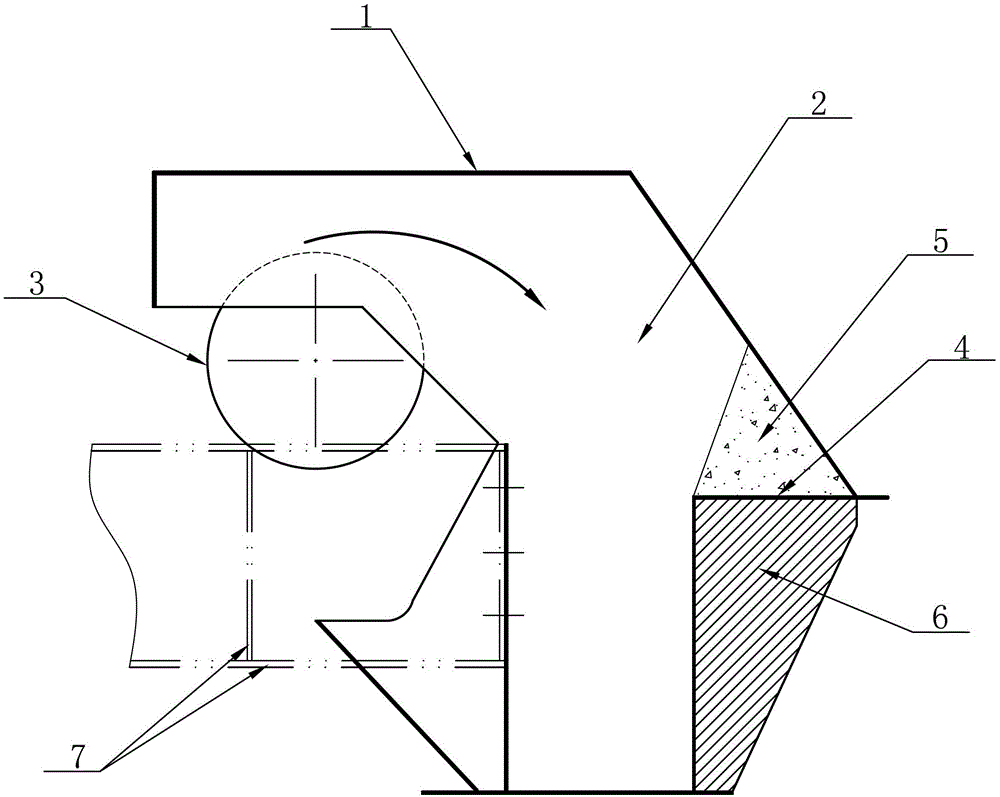

[0013] see figure 1 , a stacker redirecting hopper device disclosed in the present invention includes a hopper body 1, a material diverting channel 2 is arranged in the hopper body 1, and a driving drum 3 is arranged near the entrance of the material diverting channel 2, which is compatible with the material diverting channel 2. A material support plate 4 is fixedly arranged on the inner wall surface of the material diversion channel 2 opposite to the drive drum 3 , and the upper end surface of the material support plate 4 and the inner wall surface of the material diversion channel 2 form a stacking space 5 .

[0014] In order to make the structure of the present invention more reasonable and the work more reliable, as a preference, the material supporting plate 4 in this embodiment is arranged parallel to the upper end surface of the hopper body 1, and the side of the hopper body above the material supporting plate 4 is arranged obliquely. The angle formed by the side surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com