A single-cylinder flexible lifting mechanism for the bottom groove of an automobile body correction machine

A technology of lifting mechanism and correcting machine, which is applied in the direction of lifting frame, lifting device, etc., can solve the problems of complicated mechanism of safety leg device, increase of cylinder bore lifting pressure, slow leveling of platform, etc., and achieve simplification of protection device and increase of locking function , The effect of increasing the lifting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

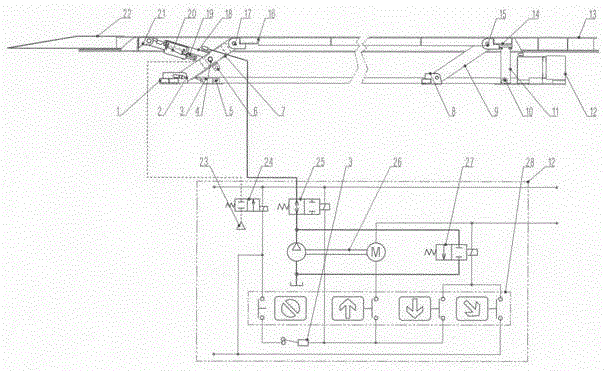

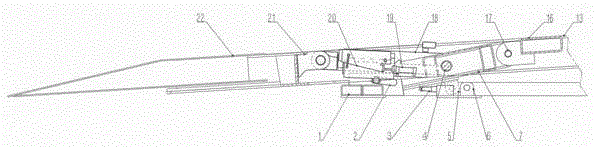

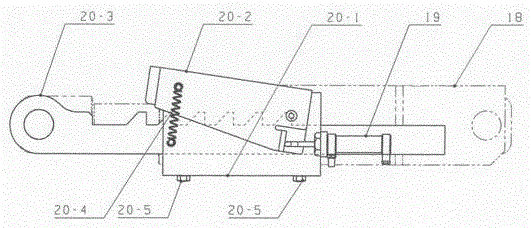

[0022] The specific embodiments of the present invention will be given below with reference to the accompanying drawings, and the present invention will be further described.

[0023] like figure 1 , the present invention comprises a base 1, a platform 13 positioned above the base 1, a front support arm 7 and a rear support arm 9 connected between the base 1 and the platform 13, and a control device 12 for controlling the lift and tilt of the platform 13 .

[0024] A first hinge support 2 and a second hinge support 8 are arranged in sequence from front to back on the base 1 . The top of the platform 13 is provided with a third hinge support 17 , a fourth hinge support 15 and a fifth hinge support 21 . Wherein the third hinge support 17 is located at the front side of the front crossbeam 16 of the platform 13 , the fourth hinge support 15 is located at the front side of the rear crossbeam 14 of the platform 13 , and the fifth hinge support 21 is located at the front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com