Anti-erosion leveling device for frame of sea tide power generation equipment

A technology of power generation equipment and leveling devices, which is applied in the direction of ocean energy power generation, hydropower generation, mechanical equipment, etc., can solve the problems of large cost of money, mechanical friction resistance that affects the degree of mechanical wear, and long time for leveling, so as to reduce the cost of digging Empty speed, effects on solving installation and leveling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

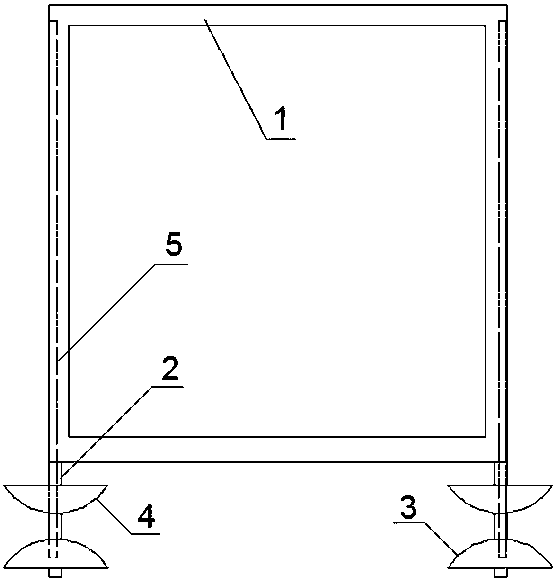

[0017] Such as figure 1 As shown, an anti-scouring and leveling device for the frame of ocean tidal power generation equipment is provided with a number of mud-in legs 2 on the outer frame 1. On each mud-in leg 2, at least one solid sinking plate 3 and an anti-scouring plate are provided from bottom to top 4. Install a high-pressure water pipe 5 on the side of the outer frame 1 where the mud leg 2 is connected. The upper end of the high-pressure water pipe 5 is provided with a connection port for connecting an external high-pressure water mechanism. The lower end of the high-pressure water pipe 5 faces the bottom of the mud leg.

[0018] The installation and leveling method of the anti-scouring leveling device of the ocean tide power generation equipment frame. When installing the ocean tide power generation equipment, insert the mud leg into the sea mud bed with the weight of the equipment, and the solid sink plate follows the mud leg and presses it into the sea mud to prevent er...

Embodiment 2

[0022] As the specific structural design of Example 1, the mud-inlet leg 2 is one of L-shaped angle steel, round hollow steel pipe, and square hollow steel pipe. When it is an L-shaped angle steel, the L-shaped right angle faces the frame.

[0023] The mud inlet leg 2 is an L-shaped angle steel, and the high-pressure water pipe is installed at the right angle of the L-shape; the mud inlet leg is a round hollow steel pipe or a square hollow steel pipe, and the high-pressure water pipe 5 is installed in the center of the circle or square through a fixing frame.

[0024] In this embodiment, the existing common materials are used to make the mud legs and the installation methods of the high-pressure water pipes. However, this example is not intended to limit the structure.

Embodiment 3

[0026] As the specific structure design of the embodiment 1, the solid sinking plate 3 and the anti-scouring plate 4 are at least a quarter circular plate, which are installed on the mud inlet leg with the connection of the mud inlet leg as the center, and are located inside the outer frame.

[0027] Preferably, the plate edge of the solid sinking plate 3 is set in a circular arc shape, which is the arc shape of the plate body toward the bottom of the inner leg; the plate edge of the anti-flush plate 4 is set in a circular arc shape, The arc is the arc from the board to the top of the mud-into-leg.

[0028] The solid sinking plate 3 and the anti-scouring plate 4 are half circular plates, which are installed on the mud inlet leg with the connection of the mud inlet leg as the center, and the quarter circular plate is located on the inner side of the outer frame and has a diameter The side is perpendicular to the direction of water flow.

[0029] In this embodiment, the structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com