Fastener for valve core of butterfly valve

A technology of fasteners and butterfly valves, which is applied in the direction of lifting valves, valve devices, wrenches, etc., can solve the problems of heavy workload, loose closing of butterfly valves, loose butterfly valve cores, etc., and achieve simple structure, convenient operation, and prevent loosening seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

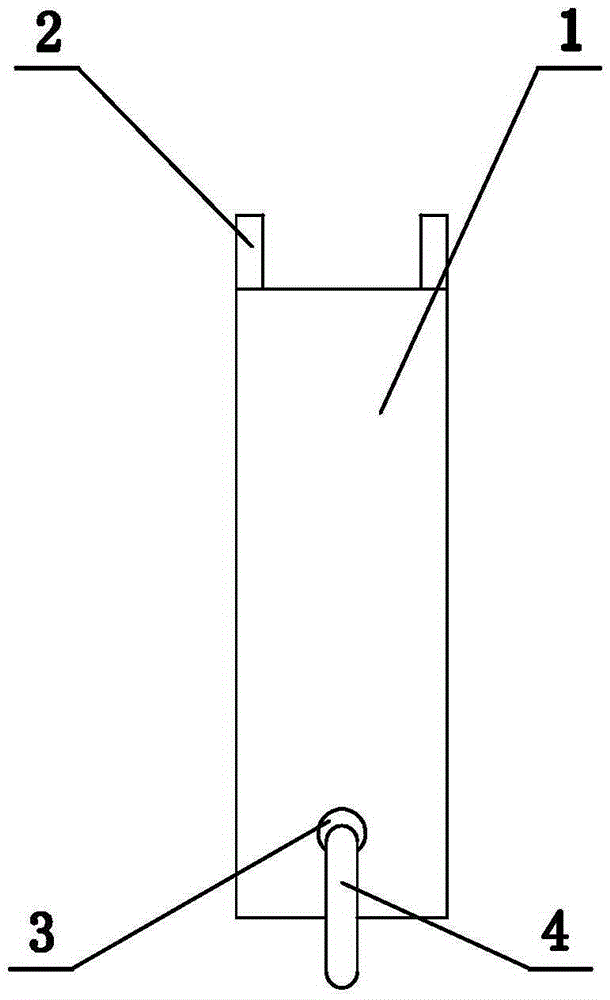

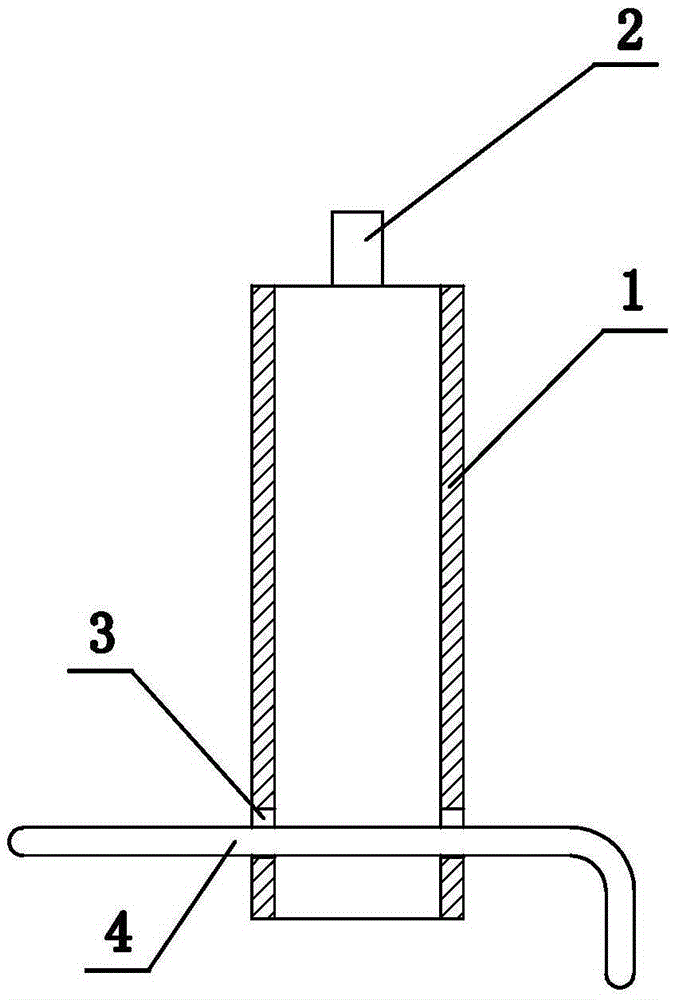

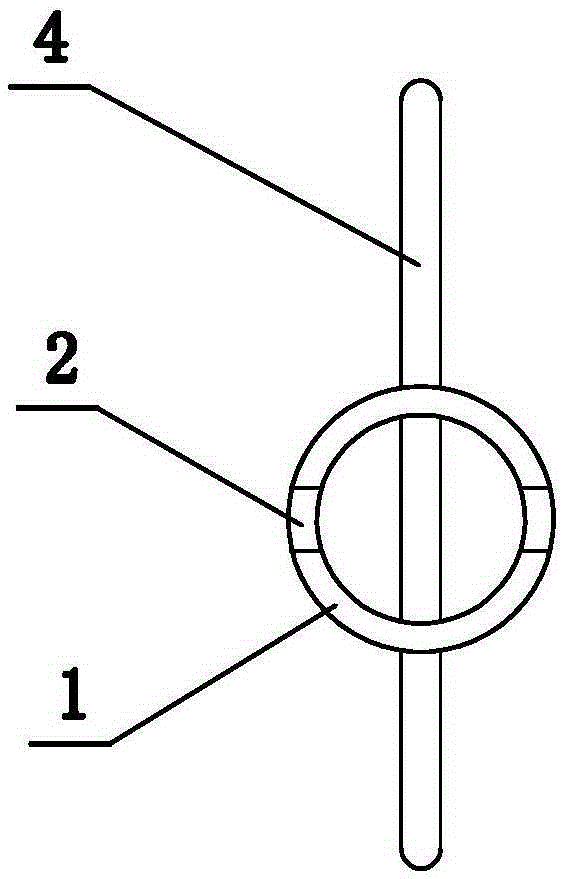

[0013] figure 1 figure 2 image 3 A butterfly valve spool fastener is introduced, the main body of which is a circular tube 1, one end of the circular tube 1 is provided with two opposite bosses 2, and the other end of the circular tube 1 is provided with a socket 3 on the wall , a lever 4 can be inserted into the jack 3. combine Figure 4 It can be seen that one end of the circular tube 1 is matched with the annular end surface of the upper end of the valve core 6 , and the two bosses 2 are matched with the two grooves on the annular end surface of the valve core 6 . According to the structure of the oil-filled butterfly valve of the current transformer or oil-invasion reactor, the round tube of this butterfly valve fastener has a length of 115mm, an outer diameter of 21mm, an inner diameter of 16mm, a tube wall thickness of 2.5mm, a boss height of 4mm, and a socket diameter of 10mm. , the above dimensional error is less than 1%.

[0014] Use as Figure 4 As shown in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com