Super large torque standard machine balance arm pull rod linkage lifting control mechanism

A technology of balance arm and lifting control, which is applied in the direction of calibration/testing of force/torque/power measuring instruments, measuring devices, instruments, etc. Effects of overshooting phenomenon, saving labor costs, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

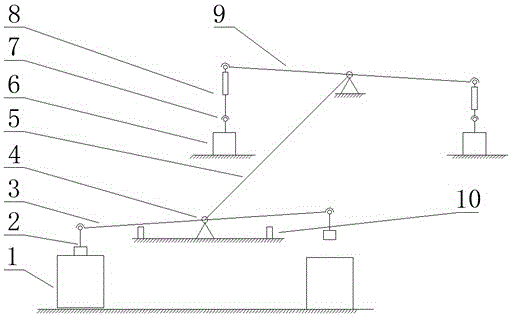

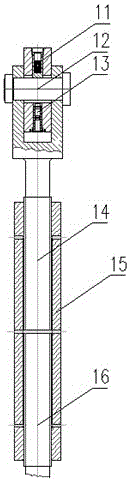

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0018] The ultra-large torque standard machine balance arm pull rod linkage lifting control mechanism of the present invention can solve the problem of leveling the ultra-large torque standard arm. In addition, the lifting speed of the pull rod designed in the present invention can be automatically adjusted according to the working conditions on site, which not only avoids the overshoot phenomenon caused by too fast speed, but also improves the working efficiency. In addition, this patented design adopts the innovative way that the lifting rod and the balance arm beam are not separated, which avoids frequent replacement of the connection link between the left and right rods of the balance arm, improves work efficiency and ensures safety. At the same time, the invention patent can realize the function of bidirectional measurement of single tooling, improve work efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com